A method of treating sludge compost conditioner by blasting technology to improve its physical and chemical properties

A technology of technical treatment and physical and chemical properties, applied in the field of physical and chemical modification of sludge composting conditioners, can solve the problems of increasing the cost of sludge composting, prolonging the cycle of sludge composting, and difficulty in recycling, etc., achieving far-reaching social significance and economic value, The effect of speeding up the recycling process and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for treating compost conditioners with high-pressure blasting technology to improve their physical properties, including the steps of raw material processing, blasting treatment, and application in composting, the specific steps are as follows:

[0027] (1) Process the raw material into a 1-2cm square conditioner;

[0028] (2) Put the conditioning agent into the blasting reaction kettle, start the blasting machine, control the reaction pressure to 3amt, hold the pressure for 30-60s, blast the time for 0.005-0.02s, and then blast;

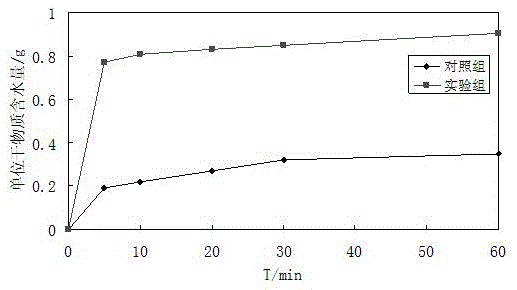

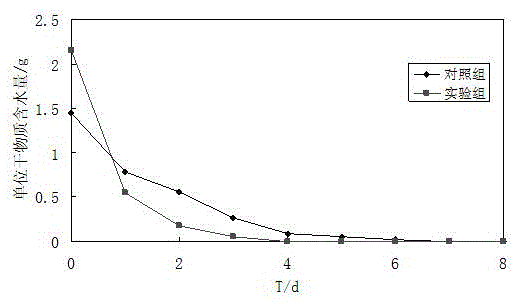

[0029] (3) Apply the blasting conditioner and the remaining sludge to the compost at a ratio of 1:3, and observe its water absorption performance. After the composting is completed, the conditioner is screened out and placed in a cool place to measure its water loss performance. The interval is 24h.

Embodiment 2

[0031] A method for treating compost conditioners with high-pressure blasting technology to improve their physical properties, comprising the steps of preparation of raw materials, processing of raw materials, blasting treatment, application in composting, etc. The specific steps are as follows:

[0032] (1) Process the raw material into a 1-2cm square conditioner;

[0033] (2) Put the conditioning agent into the high-pressure reactor, start the high-pressure blasting machine, control the reaction pressure to 4amt, hold the pressure for 30-60s, blast the time for 0.005-0.02s, and then blast;

[0034] (3) Apply the blasting conditioner and the remaining sludge to the compost at a ratio of 1:3, and observe its water absorption performance. After the composting is completed, the conditioner is screened out and placed in a cool place to measure its water loss performance. The interval is 24h.

Embodiment 3

[0036] A method for treating compost conditioners with high-pressure blasting technology to improve their physical properties, comprising the steps of preparation of raw materials, processing of raw materials, blasting treatment, application in composting, etc. The specific steps are as follows:

[0037] (1) Process the raw material into a 1-2cm square conditioner;

[0038] (2) Put the conditioning agent into the high-pressure reaction kettle, start the high-pressure blasting machine, control the reaction pressure to 5amt, hold the pressure for 30-60s, and blast the blasting time for 0.005-0.02s, and then blast;

[0039] (3) Apply the blasting conditioner and the remaining sludge to the compost at a ratio of 1:3, and observe its water absorption performance. After the composting is completed, the conditioner is screened out and placed in a cool place to measure its water loss performance. The interval is 24h.

[0040] Through the above-mentioned examples, compared with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com