Preparation method and failure analysis method for transmission electron microscope (TEM) sample

A technology of samples and failure points, which is applied in the field of TEM sample preparation, can solve the problems that cannot be achieved, and abnormal areas cannot be found.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

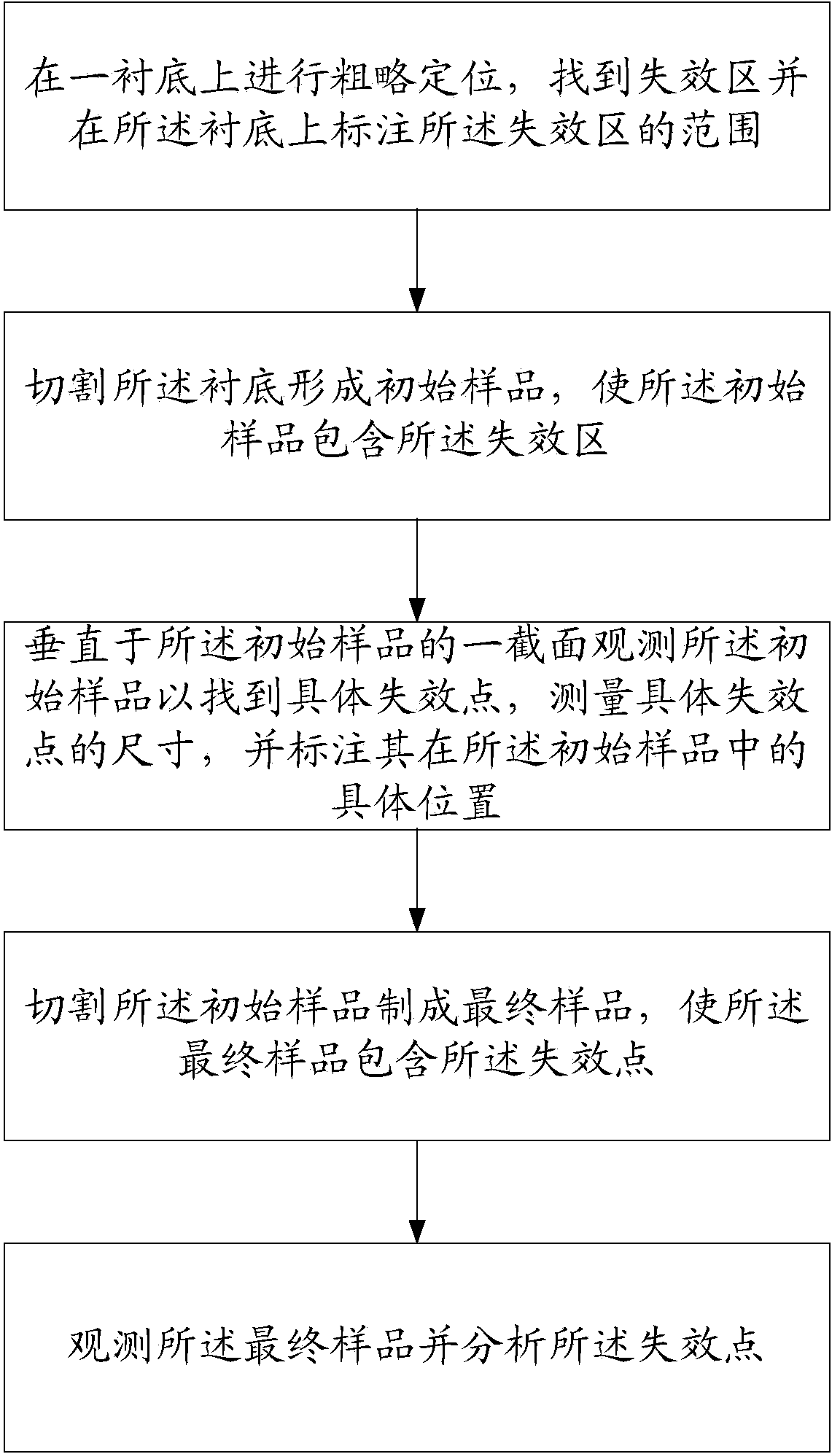

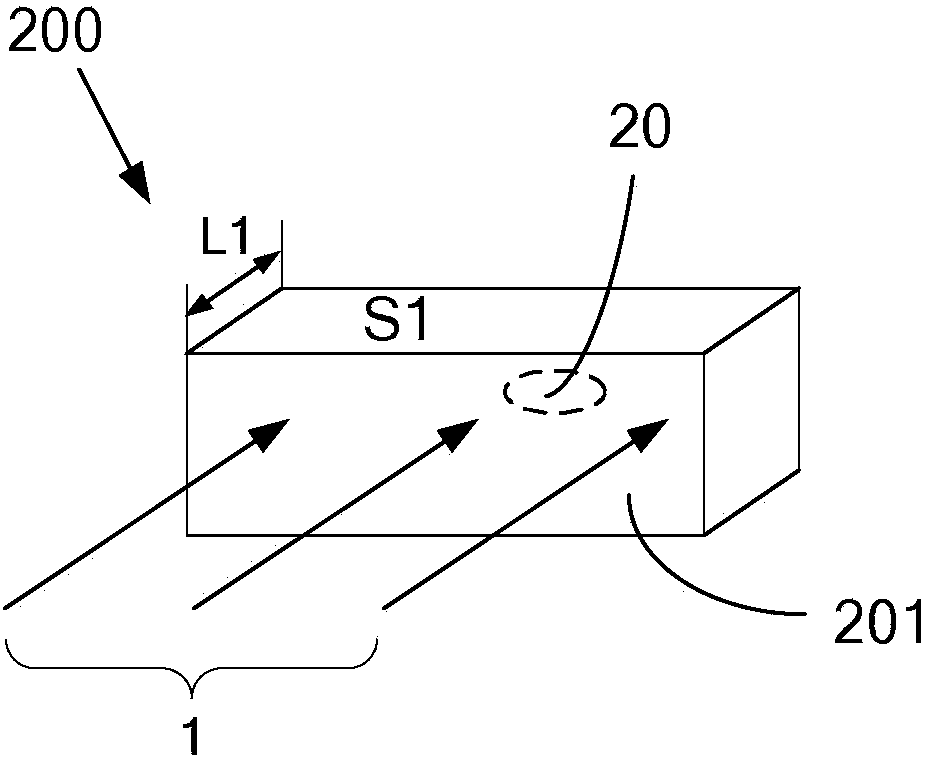

[0029] The preparation method and failure analysis method of the TEM sample provided by the present invention include the following steps:

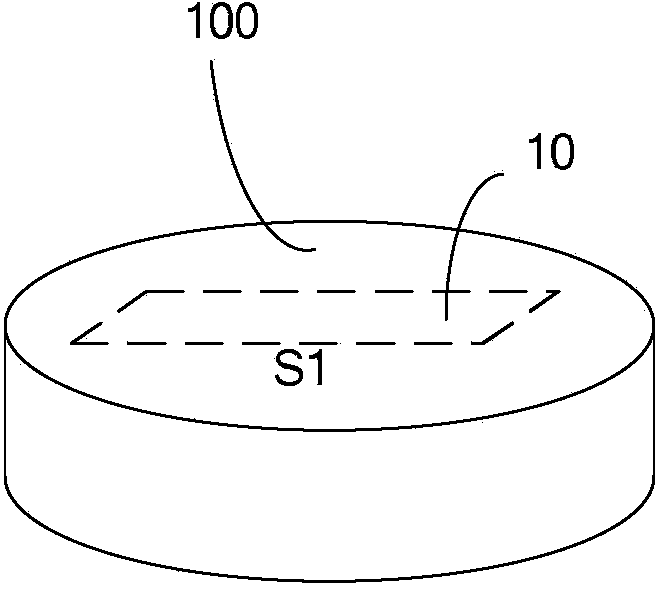

[0030] S1: Perform rough positioning on the substrate 100, find the failure area 10 and mark the range of the failure area 10 on the substrate 100.

[0031] Such as figure 1 As shown, the substrate 100 is a semiconductor substrate, which may be monocrystalline silicon, polycrystalline silicon, or amorphous silicon, or silicon, germanium, silicon germanium compound, gallium arsenide, etc., and the semiconductor substrate 100 may also have an epitaxial layer Or the silicon structure on the insulating layer, or other semiconductor materials, which are not listed here. In the substrate 100, there are a plurality of completed semiconductor devices to be inspected.

[0032] The rough positioning of the substrate 100 is intended to find the problematic semiconductor device and the approximate failure area in the device, that is, the failure area 10. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com