Method for preparing oversized neodymium iron boron material

A super-sized, neodymium-iron-boron technology, applied in magnetic materials, inductor/transformer/magnet manufacturing, permanent magnets, etc., can solve problems such as product performance and production efficiency limitations, and achieve shortened labor cycle, improved labor efficiency, and high cost performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

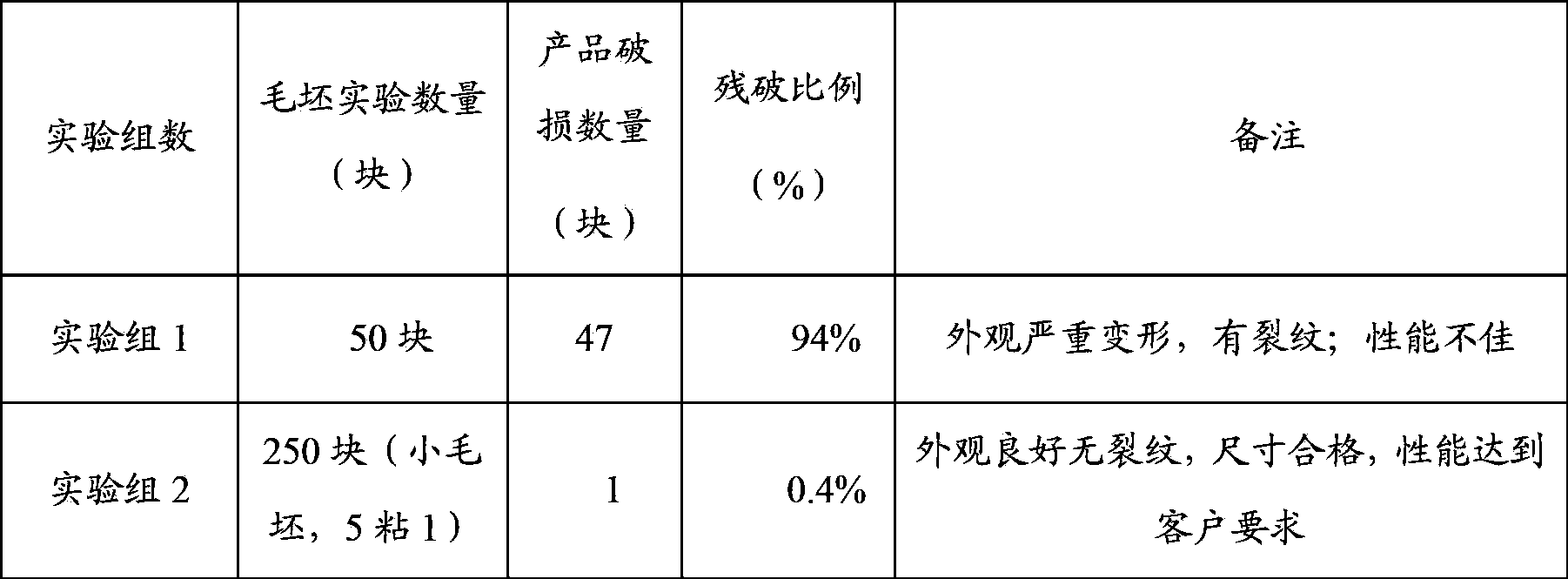

[0028] Now take a large blank with a specification of 50*50*192 (the performance of this specification is N50, which is high performance) pressed by a conventional method and a small blank with a size of 50*50*39.9 bonded and fixed according to the method of the present application as an example, and the following comparison is made test:

[0029] After smelting, powder making, molding, and sintering processes, a total of 50 super-sized blanks are pressed and formed by conventional methods in this field, each with a size of 50*50*192. After sintering, observe its appearance, measure its size and record relevant data. Statistics, as experimental group 1;

[0030] According to the method steps provided by the present invention, the forming part is pressed according to the orientation direction of the decomposed blank specification of 39.9mm, that is, the single piece of the decomposed blank is a small blank with a specification of 50*50*39.9, and the appearance is observed after...

Embodiment 2

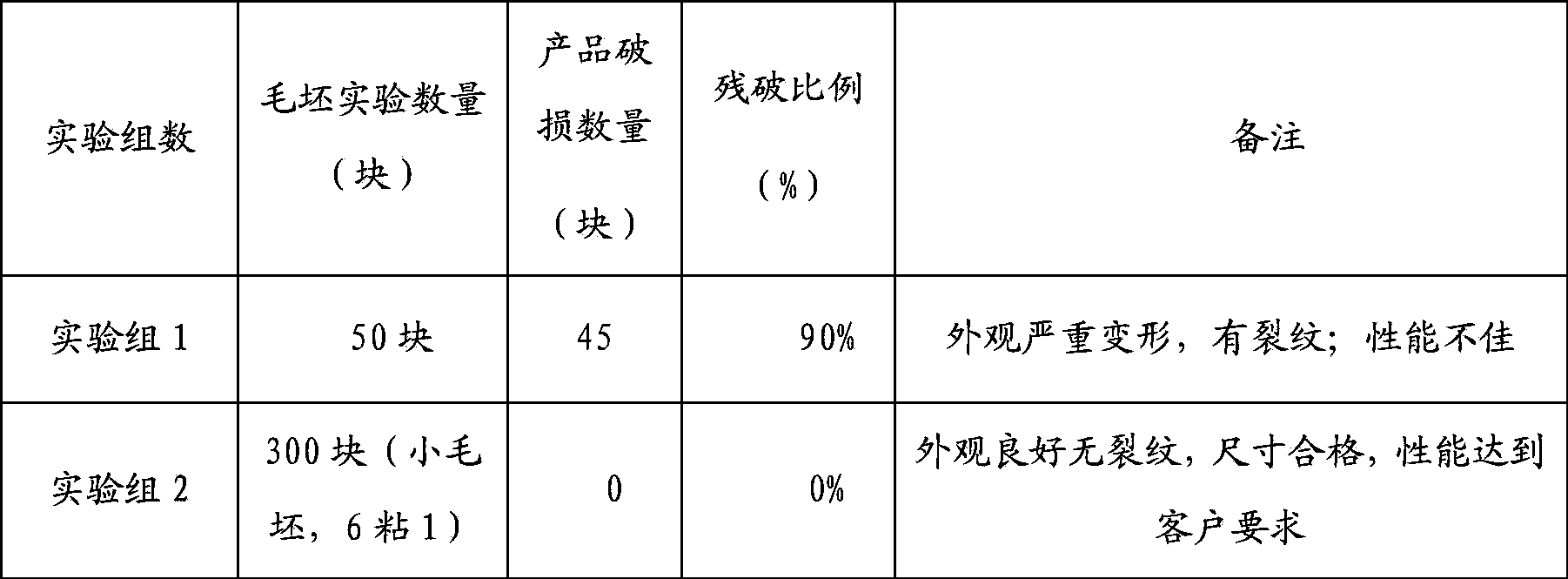

[0034] Now take a large blank with a specification of 50*50*229 (the performance of this specification is N45, low performance) pressed by a conventional method and a small blank with a size of 50*50*39.6 bonded and fixed according to the method of the present application as an example, and the following comparative test is done :

[0035] After smelting, powder making, molding, and sintering processes, a total of 50 super-sized blanks are pressed and formed by conventional methods in this field. Statistics, as experimental group 1;

[0036] According to the method steps provided by the present invention, the forming part is pressed according to the orientation direction of the decomposed blank specification of 39.6 mm, that is, the single piece of the decomposed blank is a small blank with a specification of 50*50*39.6. Record relevant data and make statistics. Then, under the condition of the same orientation direction, select the single-piece small blanks with the most rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com