Solar cell and module group thereof

A technology of solar cells and hole groups, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems that the quality of the passivation layer is greatly affected and the function of the passivation layer is affected, so as to improve the current collection effect and improve the hole filling rate , good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and embodiments. It should be noted that in the following description, similar elements are denoted by the same numerals.

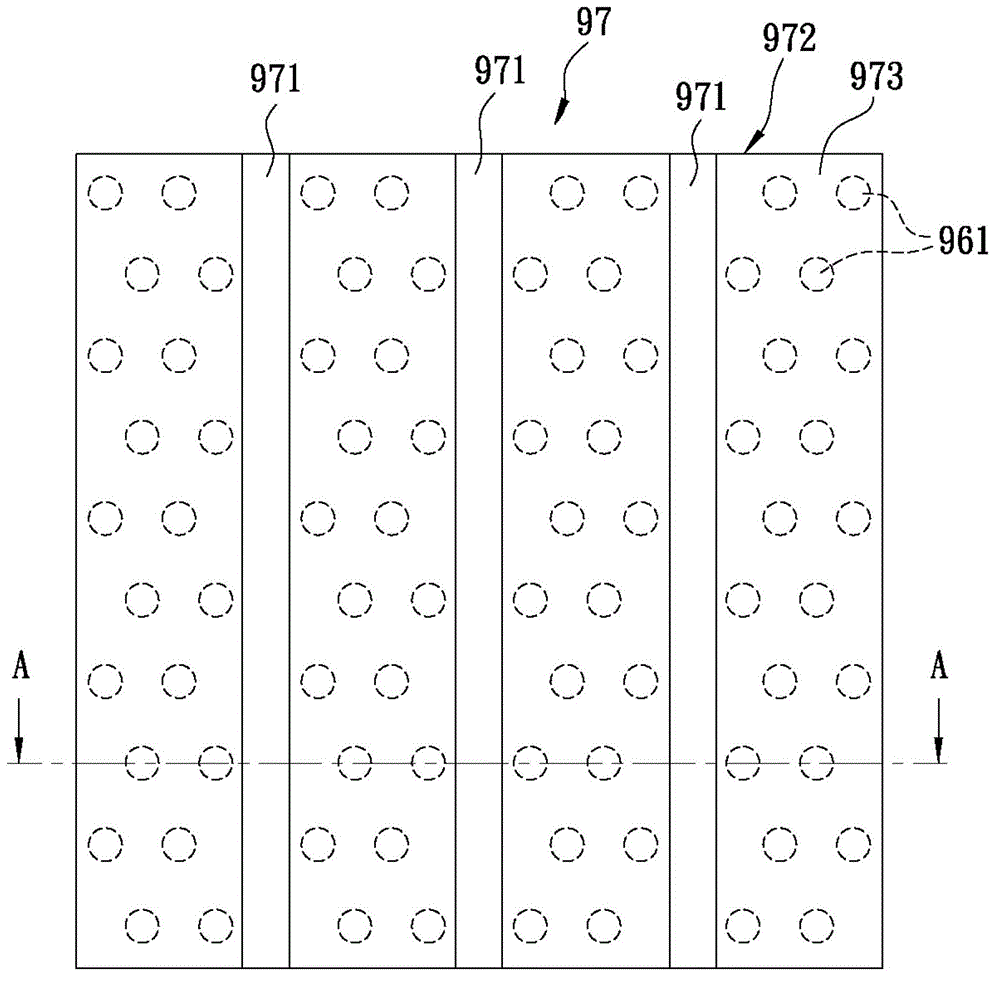

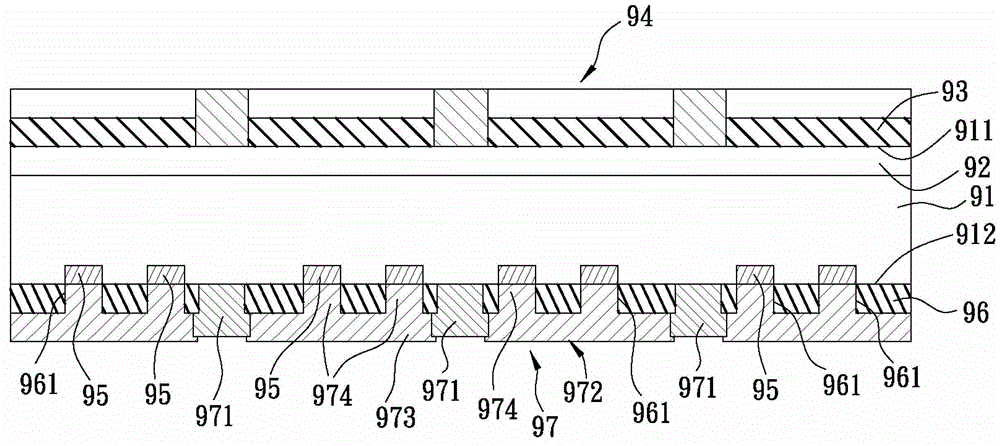

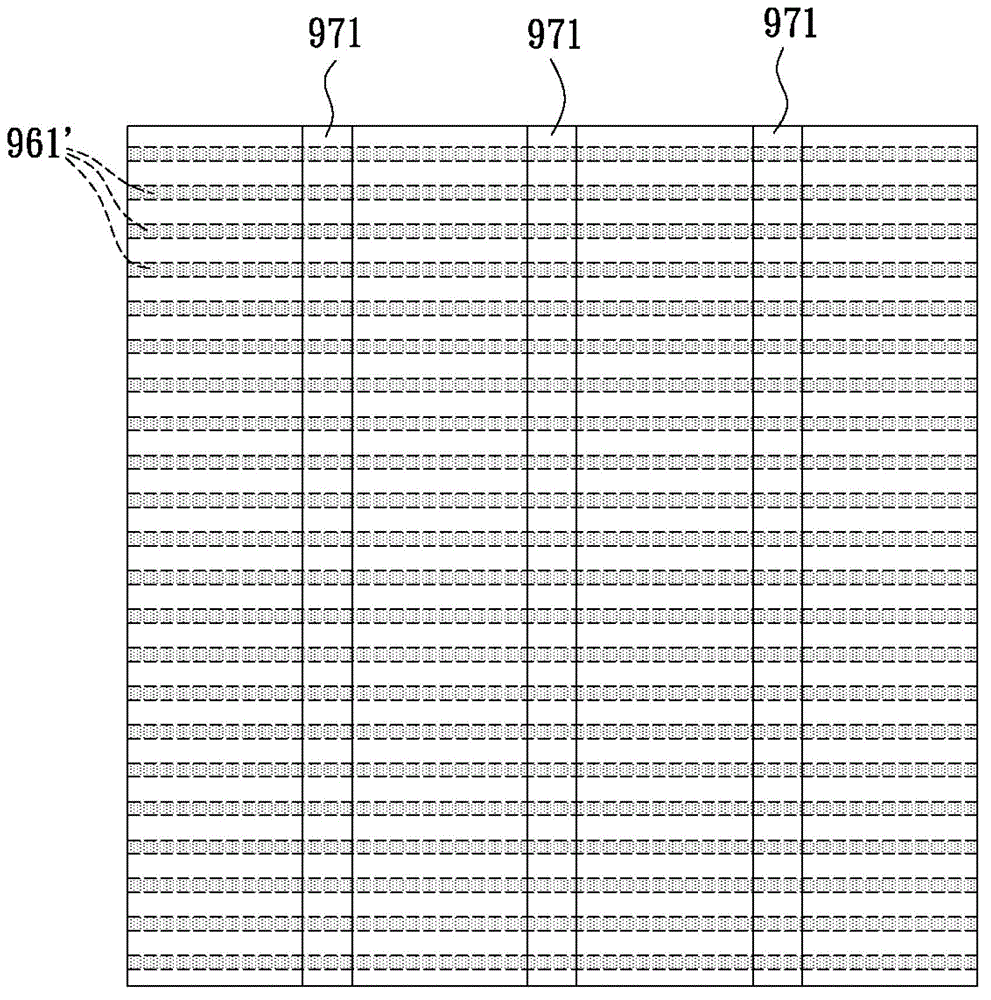

[0027] refer to Figure 4 , Figure 5 The first preferred embodiment of the solar cell module of the present invention includes: a first plate 1 and a second plate 2 arranged up and down oppositely, and a plurality of arrays are arranged between the first plate 1 and the second plate 2 solar cells 3 , and at least one packaging material 4 located between the first plate 1 and the second plate 2 and wrapping around the plurality of solar cells 3 .

[0028] The implementation of the first plate 1 and the second plate 2 is not particularly limited, glass or plastic plates can be used, and the plate on the side of the light-receiving surface of the battery must be light-transmissive. The material of the packaging material 4 is, for example, light-perme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com