Preparation method and use method of a lithium ion battery

A lithium-ion battery and lithium titanate technology, which is applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve problems such as potential safety hazards and achieve high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

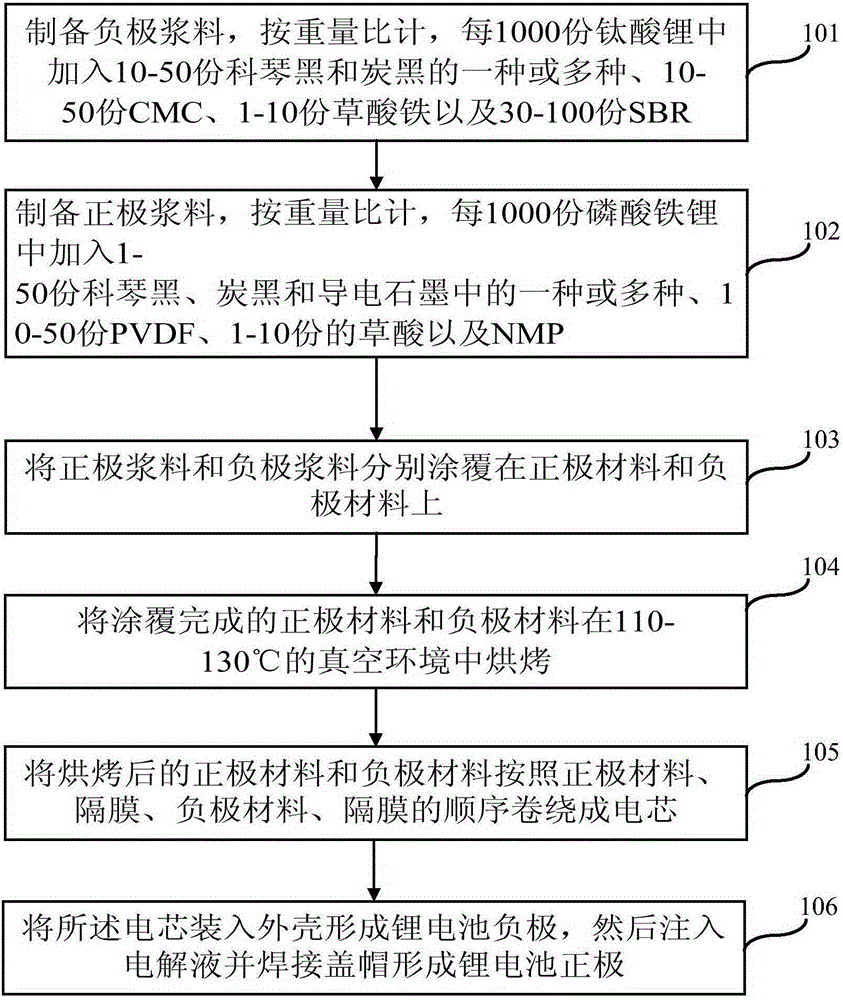

[0024] Such as figure 1 Shown, a kind of preparation method of lithium ion battery comprises the steps:

[0025] 101. Prepare the negative electrode slurry by adding 10-50 parts of one or more of Ketjen black and carbon black, 10-50 parts of CMC, 1-10 parts of iron oxalate and 30-100 copies of SBR;

[0026] 102. Prepare positive electrode slurry by adding 1-50 parts of one or more of Ketjen black, carbon black and conductive graphite, 10-50 parts of PVDF, 1-10 parts of lithium iron phosphate per 1000 parts of lithium iron phosphate by weight ratio parts of oxalic acid and NMP;

[0027] 103, coating the positive electrode slurry and the negative electrode slurry on the positive electrode material and the negative electrode material respectively;

[0028] 104, baking the coated positive electrode material and negative electrode material in a vacuum environment at 110-130°C;

[0029] 105, winding the baked positive electrode material and negative electrode material into a bat...

Embodiment 2

[0045] This embodiment provides a method for using a lithium-ion battery produced according to the method for preparing a lithium-ion battery in the above-mentioned embodiments, and the lithium-ion battery is used to replace alkaline dry batteries and is used in electronic products.

[0046] At present, the initial voltage of alkaline dry batteries produced in China is basically 1.66V, and the termination discharge voltage is zero V. However, as long as the adaptive voltage of domestic ordinary household electronic products is controlled between 1.2V and 1.6V, it is completely consistent with the voltage of alkaline dry batteries, and the termination voltage of the lithium-ion battery is controlled at 1.2V, which has better performance than alkaline dry batteries. Potential and voltage range advantage, it is a safer and more reliable new environmentally friendly battery to replace alkaline batteries for household electronic products and electric toys.

[0047]The lithium-ion b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com