Shelf stable, brewed beverage concentrates and methods of making the same

A technology for concentrates and beverages, applied in tea flavors, coffee flavors, food science, etc., can solve the problems of increasing processing and melting costs and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A non-aqueous fluid coffee concentrate composition "A" (100% by weight) was prepared by spoon stirring spray-dried soluble coffee powder (Robusta; 33% by weight) in NAL (propylene glycol; 67% by weight). The mixture was then heated in a microwave oven at full power for a total of 1 minute to a temperature of 180°F while moving the mixture every 10 seconds and stirring with a spoon to effectively dissolve or disperse all of the coffee in the NAL.

[0071] A comparative non-aqueous coffee concentrate composition "B" (100% by weight) was prepared by spoon stirring the same spray-dried soluble coffee powder (Robusta; 33% by weight) in distilled water (67% by weight). The mixture was then heated in a microwave oven at full power to a temperature of 180°F, followed by stirring with a spoon for 1 minute to dissolve all coffee solids in the water.

[0072] The two coffee concentrates were stored at 37 °C for 30 days in 20 mL capped glass vials under air headspace. Concentrates...

Embodiment 2

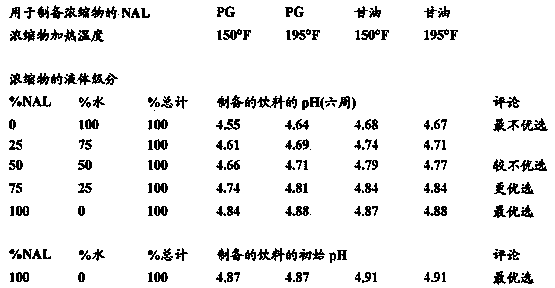

[0074] Non-aqueous fluid coffee concentrate "A" (100% by weight) was prepared by spoon stirring spray-dried soluble coffee powder (Robusta; 33% by weight) in NAL (propylene glycol; 67% by weight). The mixture was then heated in a microwave oven to a temperature of 200°F and held at that temperature for 10 minutes while stirring with a spoon to dissolve or disperse all of the coffee in the NAL.

[0075] Comparative non-aqueous fluid coffee concentrate "B" (100% by weight) was prepared by spoon stirring spray-dried soluble coffee powder (Robusta; 33% by weight) in NAL (1,3-propanediol; 67% by weight) . The mixture was then heated in a microwave oven to a temperature of 200°F and held at that temperature for 10 minutes while stirring with a spoon to dissolve or disperse all of the coffee in the NAL.

[0076] The two coffee concentrates were stored at 37 °C for 10 days in 20 mL capped glass vials under air headspace. The product was removed from storage and added individually to...

Embodiment 3

[0078] Fluid non-aqueous coffee concentrate "A" (100% by weight) was prepared as follows: At room temperature, in NAL (caprylic / capric triglycerides, NEOBEE M-5™, available from Stepan Co., Northfield, IL; 67% Spray-dried soluble coffee powder (Robusta; 33% by weight) was manually agitated in 2 wt. %, and the mixture was subsequently subjected to high-shear mixing using a rotor-stator type mixer (Heidolph: Silent Crusher-M, at 50,000 rpm) to Grinds and disperses coffee in a smooth and homogeneous suspension.

[0079] Fluid coffee concentrate "B" (100% by weight) was prepared by spoon-stirring spray-dried soluble coffee powder (Robusta; 33% by weight) in distilled water (67% by weight) at room temperature. The mixture was then mixed using a rotor-stator type mixer (Heidolph: Silent Crusher-M at 50,000 rpm) to grind and dissolve all coffee solids in a smooth homogeneous solution.

[0080]Store both concentrates at 37 °C for 30 days in 20 mL capped glass vials under air headspac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com