Device and method for manufacturing aerated concrete block through impact and tensile hole drilling and cutting grooving

A technology of air-entrained concrete and hole drawing, which is applied in the direction of manufacturing tools and ceramic molding machines, etc., which can solve the problems of large fluctuations in the quality of tie rib grooves, poor dusty environment, and high labor costs, and achieve low efficiency and improved efficiency. The effect of high construction environment and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

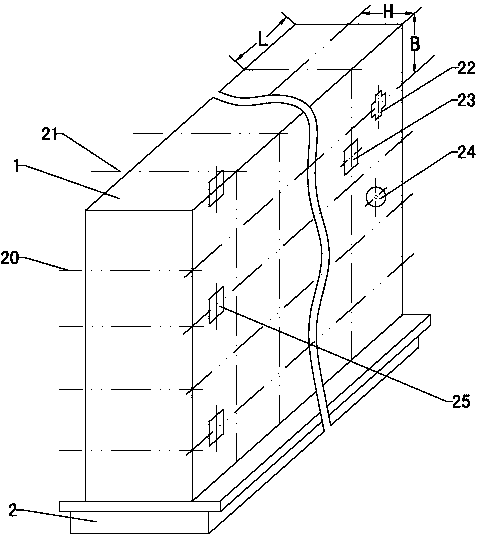

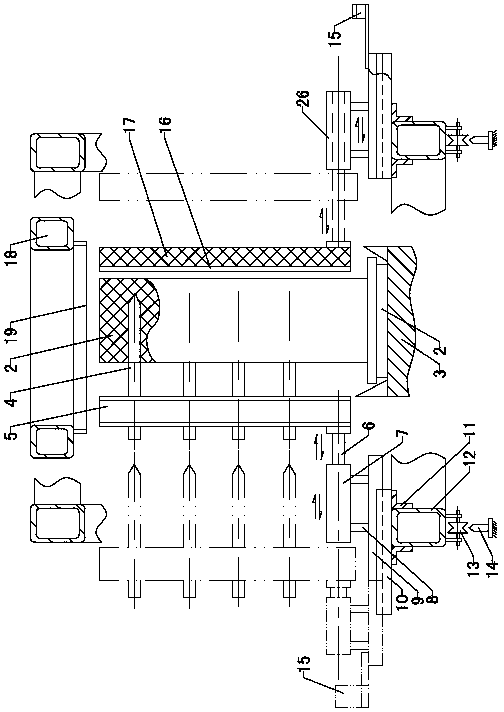

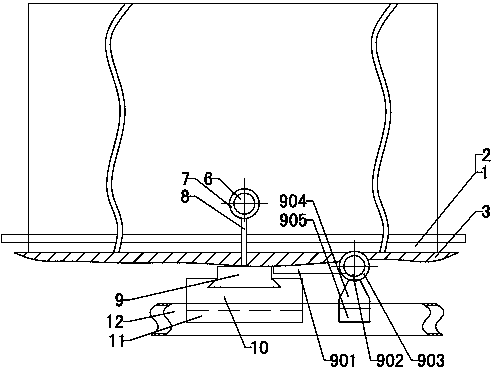

[0029] Refer to attached Figure 1~5 : In the present embodiment, block size is long 600mm, high 240mm, wide 200mm; Groove is in the middle position of the top surface of block, and its axis is consistent with the length direction of 600mm of block, and its section is deep 7mm, wide 14mm , the bottom fillet R=2,5mm; the nominal size of the embryo body is: 4200mm long, 1200mm high, 600mm wide; on the flip cutting machine production line, a punching and pulling hole forming device is added to make the block.

[0030] A device for punching and drawing holes and cutting into grooves to prepare aerated concrete blocks, including a cutting table 3 and an embryo body carrier plate 2 laid on the top of the cutting table 3, and longitudinal cutting units are arranged on the left and right sides of the embryo body 1, and on the embryo body 1, a horizontal cutting unit is set above, and a punching and drawing device that can move forward and backward in parallel is arranged on both sides...

Embodiment 2

[0051] combined with Figure 1~5 : In this embodiment, the size of the block is 600mm long, 300mm high, and 200mm wide (see figure 1 The right end of the mesoderm 1), the groove is on the side of the block, the cross section is a semi-circular arc with R=30mm, the width is 60mm, the depth is 70mm, and the mouth has a rectangular step with a width of 90mm and a depth of 12mm.

[0052] This embodiment is similar to Embodiment 1, the difference is:

[0053] 1. The layout and cutting plan of the blocks on the embryo body 1 is as follows: in the direction of the embryo body 4200 mm, the length of the block is obtained by cross-cutting the separation surface 21; in the direction of the embryo body 600 mm, the Longitudinal separation surface 20 obtains the height of 300mm of block; in the direction of embryo body 1200mm, obtains the 200mm width of block by longitudinal separation surface 20 (see figure 1 The right end of mesoembryo body 1), the groove is in the middle of the side...

Embodiment 3

[0058] to combine Figure 1~5 , in this embodiment, the size of the block is 600mm long, 240mm high, and 200mm wide; Fillet R=2.5mm; On the production line of the embryo body whose nominal size is 4200mm long, 1200mm high, and 600mm wide, the block is made by installing a punching and pulling hole forming device on the production line using a flip cutting machine.

[0059] It is basically the same as Embodiment 1, except that the punching and drawing hole II 23 is set on the cross-cutting separation surface 21, and the position of the fixed punching and drawing tool 4 on the tool holder 5 is changed correspondingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com