Method for monitoring biological treatment oxygen uptake rate of sewage and controlling aeration quantity

A sewage biological treatment, oxygen absorption rate technology, applied in the direction of sustainable biological treatment, aerobic process treatment, flow control using electrical devices, etc., can solve the problems of low measurement frequency, increased equipment investment, small measurement value, etc., to avoid The effect of excessive aeration, excellent control effect and accurate aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: sequence batch (SBR) activated sludge method

[0035] The specific steps are as follows:

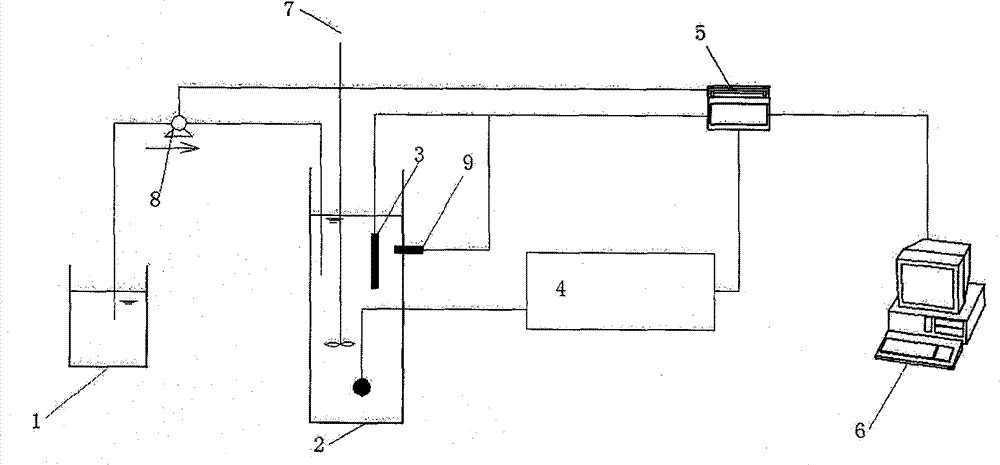

[0036] Step 1: Measure the oxygen transfer coefficient K of aeration and oxygenation under different air flow q (0, 30, 40, 60, 80, 120L / h) and temperature changes L a(d -1 ) and the saturated dissolved oxygen concentration Osat (mg / L), to obtain the oxygen transfer coefficient K L The quantitative relationship between a and gas supply q and temperature T.

[0037] Determination of oxygen transfer coefficient K L The quantitative relationship between a and gas supply q is as follows:

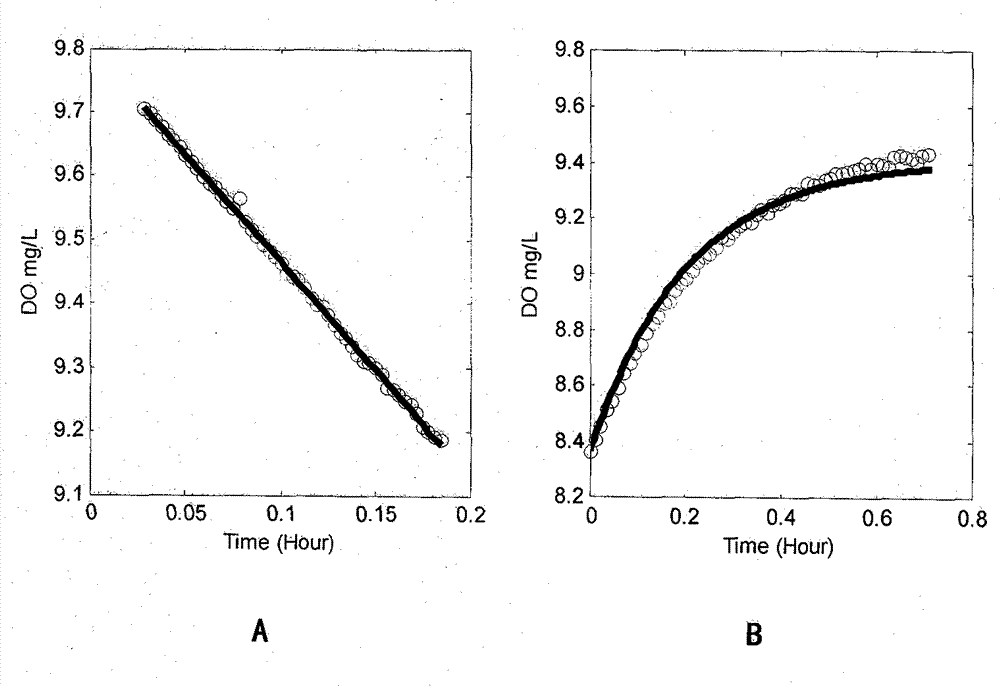

[0038] 1) Continuously aerate the activated sludge in the reactor for more than 12 hours, so that the sludge is in an endogenous respiration state, and keep the sludge concentration stable during the measurement process, so as to avoid the impact of the sludge concentration on K L a and the impact of Osat;

[0039] 2) Stop the aeration for 15 minutes, use the computer data acquis...

Embodiment 2

[0052] Embodiment 2: continuous activated sludge process

[0053] The specific steps are as follows:

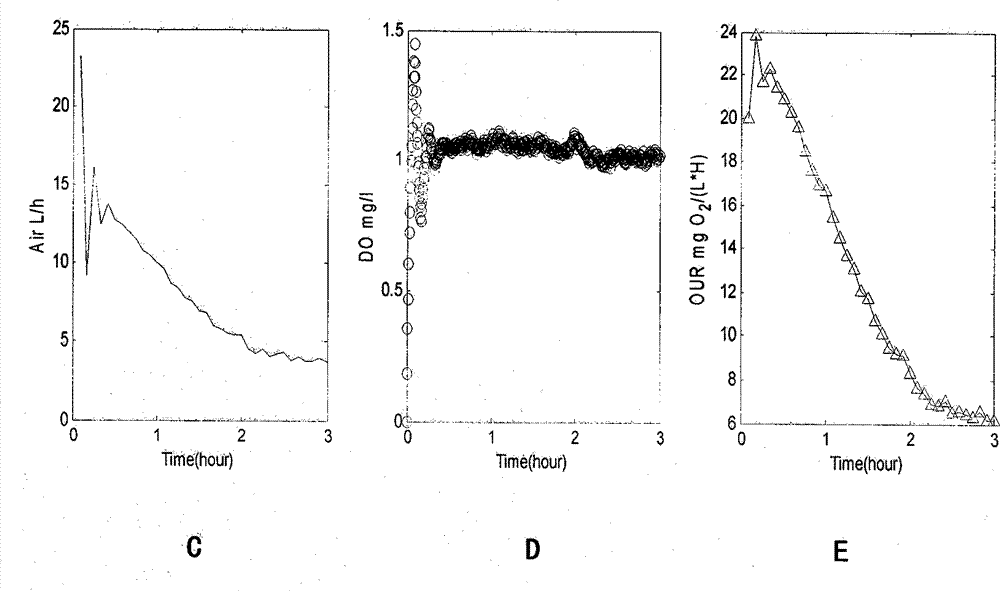

[0054] Step 1: Transform the reactor in the SBR implementation case to make it continuously feed water, change the feed water flow rate, make the residence time (HRT) of the continuous reactor be 8 hours, and set up a sedimentation tank with a residence time of 4 hours, the sedimentation tank The sludge reflux ratio is 2. The influent flow is continuously changed based on the 8-hour average residence time to simulate the fluctuation of sewage volume within a day. Oxygen transfer coefficient K in the continuous reactor L The relationship between a and gas supply q is the same as that of SBR reactor, see formula (4).

[0055] Step 2: Estimate the 5-minute period online (T 1 ) within OUR. Provide air flow q to the reactor 1 =10L / h, in the next 5 minutes, use the computer data acquisition system to record the dissolved oxygen concentration at a frequency of once every 10 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com