Methods for preparing compact silicon nitride ceramic material and compact special-shaped silicon nitride ceramic material by virtue of aqueous tape casting

A technology of water-based tape casting and silicon nitride ceramics, which is applied in the field of preparing silicon nitride ceramic materials, can solve the problems of low density of dense special-shaped silicon nitride ceramic materials, small size of sintered blocks, and low density. Superior processing performance, high strength and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

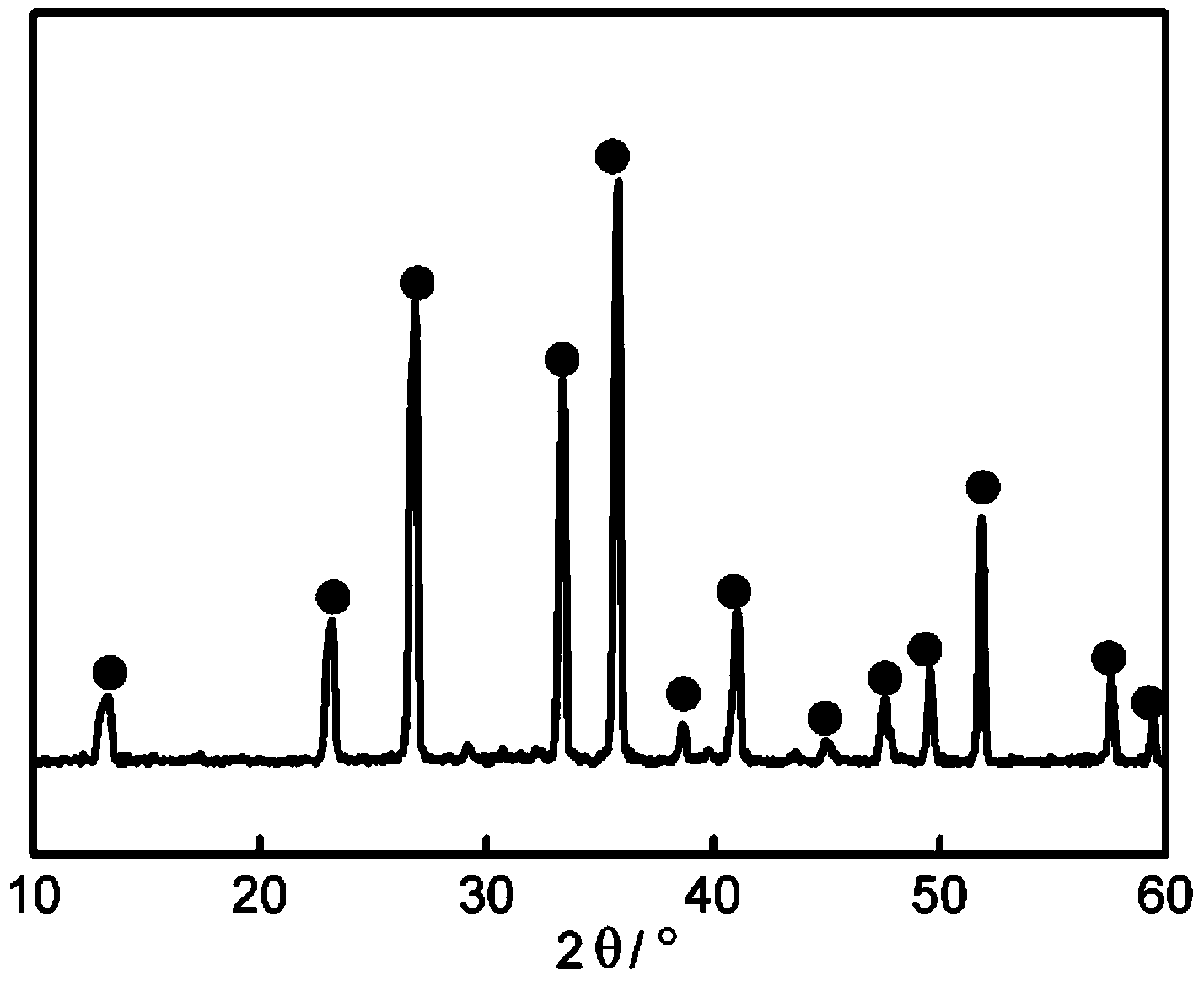

[0052] Embodiment 1: This embodiment is a method for preparing dense silicon nitride ceramic materials by water-based tape casting, which is completed according to the following steps:

[0053] 1. Adding sintering aids: First, use absolute ethanol to mix silicon nitride powder and sintering aids powder, stir for 20h-24h at a stirring speed of 300r / min-350r / min, and then stir at a temperature of 50 Dry at ℃~80℃ for 10~12 hours, then mechanically pulverize and sieve to obtain silicon nitride / sintering aid powder;

[0054] The silicon nitride powder described in step 1 accounts for 90% to 95% of the total mass of the silicon nitride powder and the sintering aid powder;

[0055] The sintering aid powder described in step 1 accounts for 5% to 10% of the total mass of the silicon nitride powder and the sintering aid powder;

[0056] The volume ratio of the total mass of the silicon nitride powder and sintering aid powder described in step 1 to absolute ethanol is 1g:(10mL-15mL);

...

specific Embodiment approach 2

[0074] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass ratio of the polyvinyl alcohol solution described in step 2 to the silicon nitride / sintering aid powder is (0.06-0.08):1. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

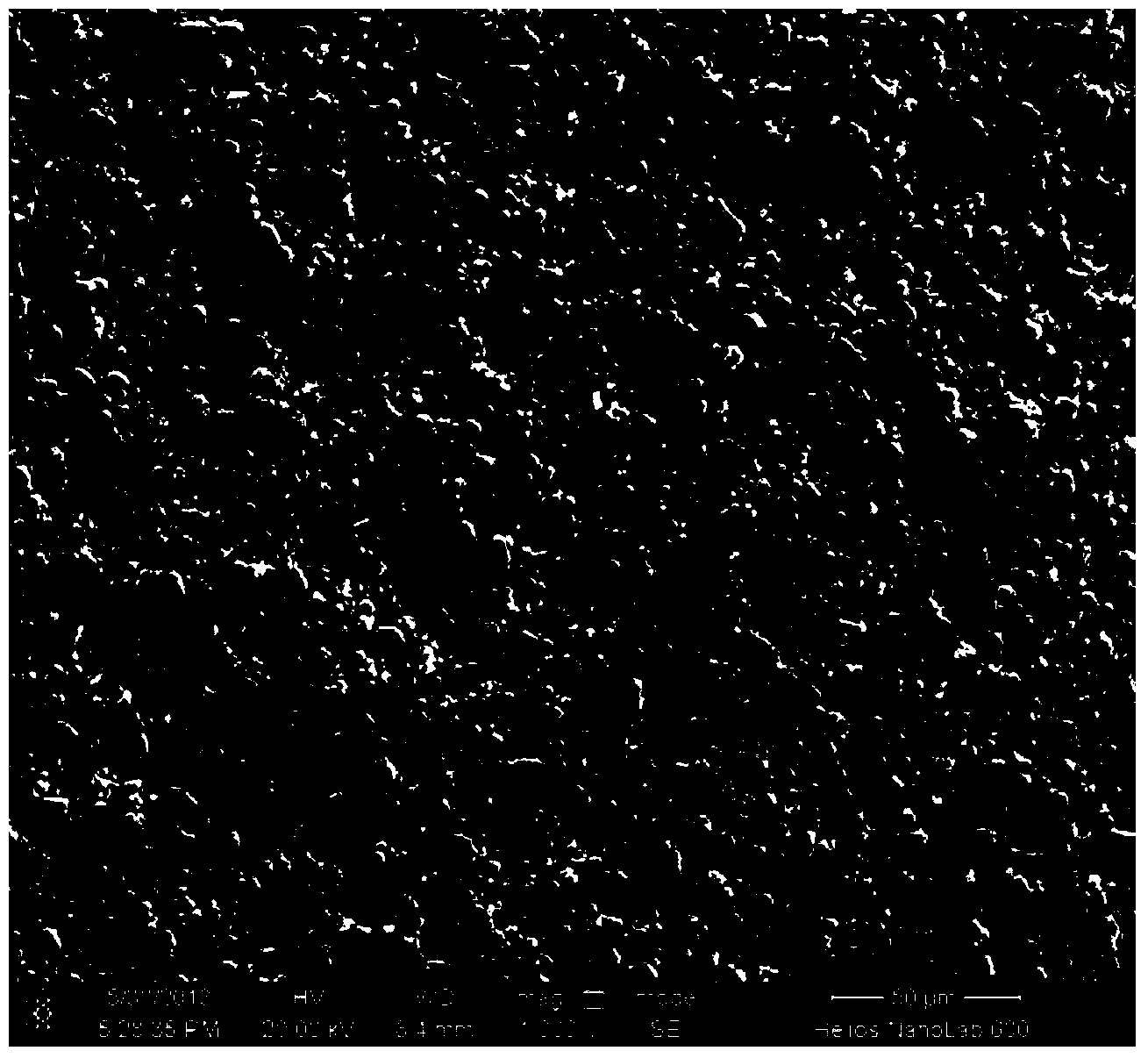

[0075] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 3, the slurry is poured on the glass substrate for tape casting, and the speed of the scraper during the tape casting process is 15cm / min~20cm / min, drying the flow-cast slurry at room temperature for 16h-20h, peeling off the glass substrate to obtain a silicon nitride ceramic green tape with a thickness of 200μm-300μm. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com