Binder for monolithic refractory material and preparation method thereof

A technology of refractory materials and binders, which is applied in the field of binder preparation, can solve the problems of low thermal strength and poor slag resistance, and achieve the effects of improving performance, reducing the risk of bursting, and saving baking costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

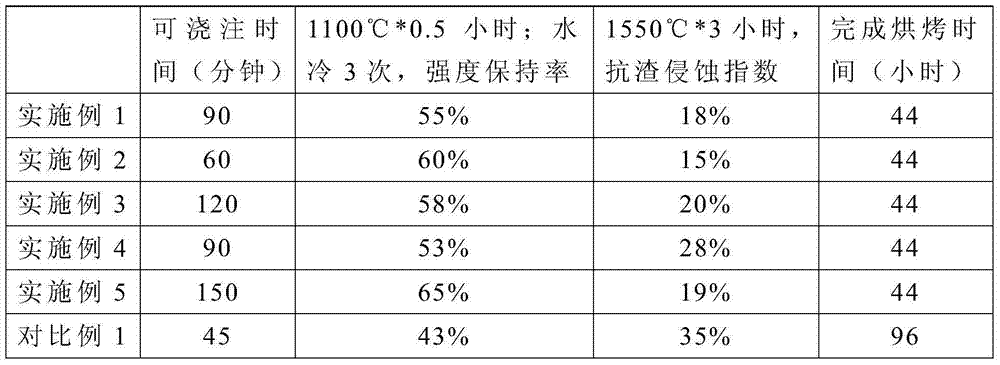

Examples

Embodiment 1

[0020] The mass fraction is 50% of aluminum oxide and 40% of magnesium oxide and 10% of the activator by ball mill grinding for 30 minutes, the mass fraction of metasilicate in the activator mixture is 80%, polycarboxylic acid in the activator mixture The mass fraction of silicon is 10%, and the mass fraction of elemental silicon in the activator mixture is 10%; obtain a binder for amorphous refractories with a median particle size of 8 microns and a 90 micron sieve of 2.5%.

Embodiment 2

[0022] The mass fraction is 60% of aluminum oxide and 35% of magnesium oxide and 5% of the activator by ball mill grinding for 30 minutes, the mass fraction of metasilicate in the activator mixture is 60%, polycarboxylic acid in the activator mixture The mass fraction of silicon is 30%, and the mass fraction of elemental silicon in the activator mixture is 10%; obtain a binder for amorphous refractories with a median particle size of 5 microns and a 90 micron sieve of 1%.

Embodiment 3

[0024] The mass fraction is 40% of aluminum oxide and 40% of magnesium oxide and 20% of the activator by ball mill grinding for 30 minutes, the mass fraction of metasilicate in the activator mixture is 40%, polycarboxylic acid in the activator mixture The mass fraction of silicon is 40%, and the mass fraction of elemental silicon in the activator mixture is 20%; obtain a binder for amorphous refractories with a median particle size of 14 microns and a 90 micron sieve of 4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com