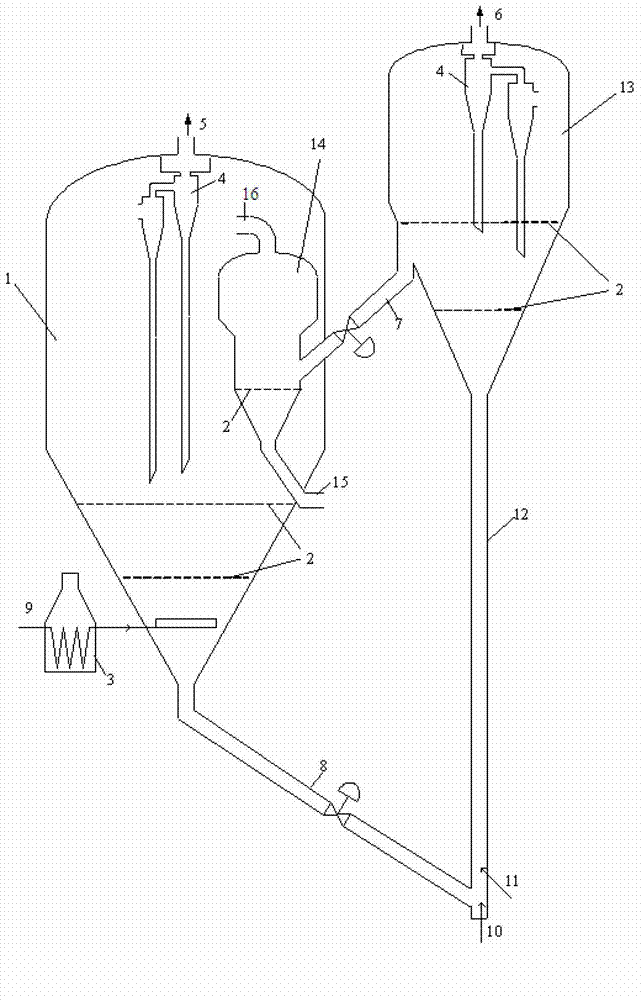

Continuous reaction regeneration device utilizing vulcanization catalyst to perform alkane dehydrogenation

A technology for alkane dehydrogenation and reaction regeneration, which is applied in catalyst regeneration/reactivation, physical/chemical process catalyst, catalyst activation/preparation, etc. , The effect of reducing heat dissipation loss and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The feed rate of the propane raw material is 5kg / h, and the raw material contains hydrogen sulfide, and its content is 0.5wt% in terms of sulfur. After the raw material is preheated by the heating furnace, it enters the reactor through a ring pipe equipped with multiple nozzles. There are two layers of distribution plates inside, and the opening ratio is 45%. The reaction temperature is 590°C, and the axial superficial gas velocity under the actual reaction conditions in the reactor is 0.5m / s; the reacted catalyst then enters the regenerator, and the temperature in the regenerator is controlled at 750°C, and the supplementary fuel of the catalyst For diesel, the temperature of the regenerator is controlled by the amount of diesel, and the average residence time of the catalyst in the regenerator is 9 minutes. Then the regenerated catalyst enters the pre-sulfurizer built into the reactor through the regenerated inclined pipe, with an average residence time of 5 minutes. ...

Embodiment 2

[0057] The raw material of this embodiment contains isobutane, and its composition is as shown in Table 1. During the dehydrogenation reaction, the reaction temperature is 560 ° C, and the axial superficial gas velocity in the reactor is 0.35m / s. In addition to the above differences, See embodiment 1 for other technological processes and process parameters. The product distribution after catalytic dehydrogenation is shown in Table 2, the conversion rate of isobutane is 65.59wt%, and the selectivity of isobutene is 84.51wt%.

Embodiment 3

[0059] Propane (composition in the propane raw material is as shown in Table 1) the feed rate of raw material is 5kg / h, contains hydrogen sulfide in the raw material, and its content is 1.0wt% in sulfur, raw material is preheated to 400 ℃ through heating furnace, passes The loop pipe with multiple nozzles enters the reactor, and two layers of distribution plates are arranged in the reactor, and the opening ratio is 45%. The reaction temperature is 650°C, and the axial superficial gas velocity under the actual reaction conditions in the reactor is 0.02m / s; the reacted catalyst then enters the regenerator, and the temperature in the regenerator is controlled at 550°C, and the supplementary fuel of the catalyst For diesel, the temperature of the regenerator is controlled by the amount of diesel, and the average residence time of the catalyst in the regenerator is 9 minutes. Then the regenerated catalyst enters the built-in presulfurizer of the reactor through the regenerated incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com