Special putty for spray coating polyurea elastomer and preparation method thereof

A technology of putty and active diluent, applied in the direction of filling slurry, etc., can solve the problem of not being able to significantly improve the adhesion of substrates and special primers, and achieve the effect of good matching and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

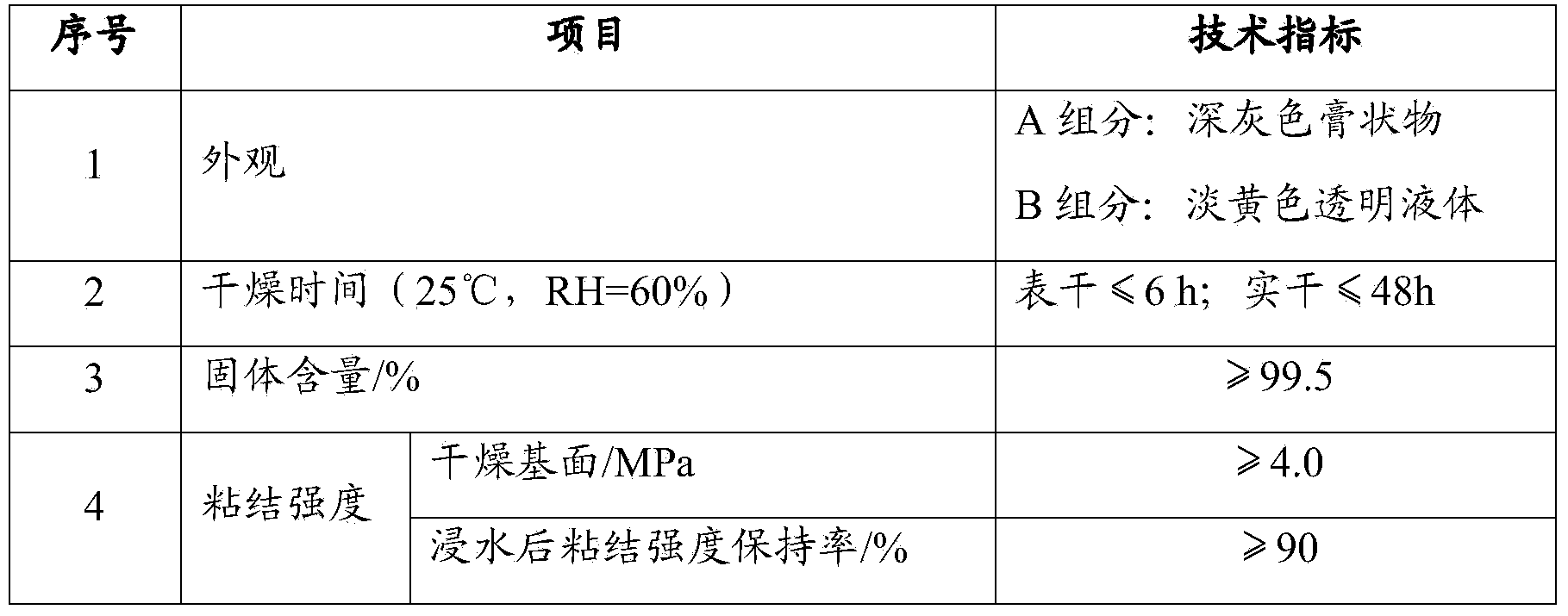

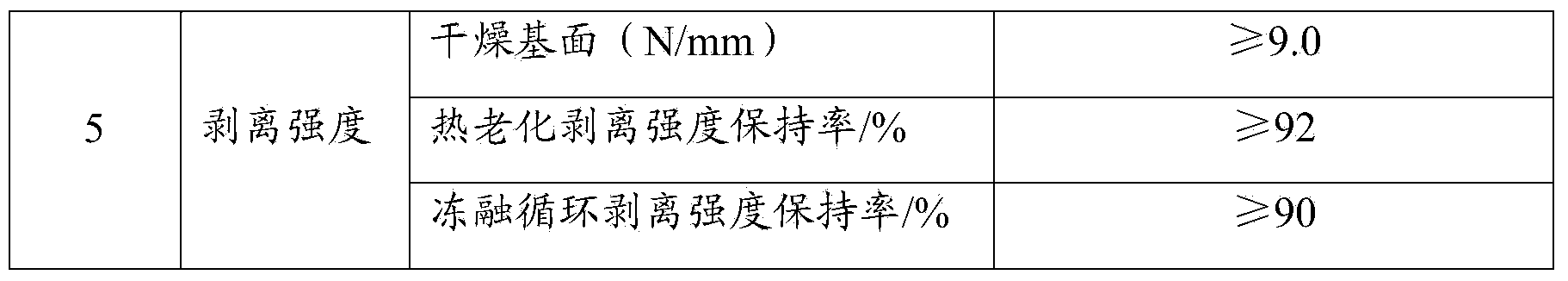

Image

Examples

preparation example Construction

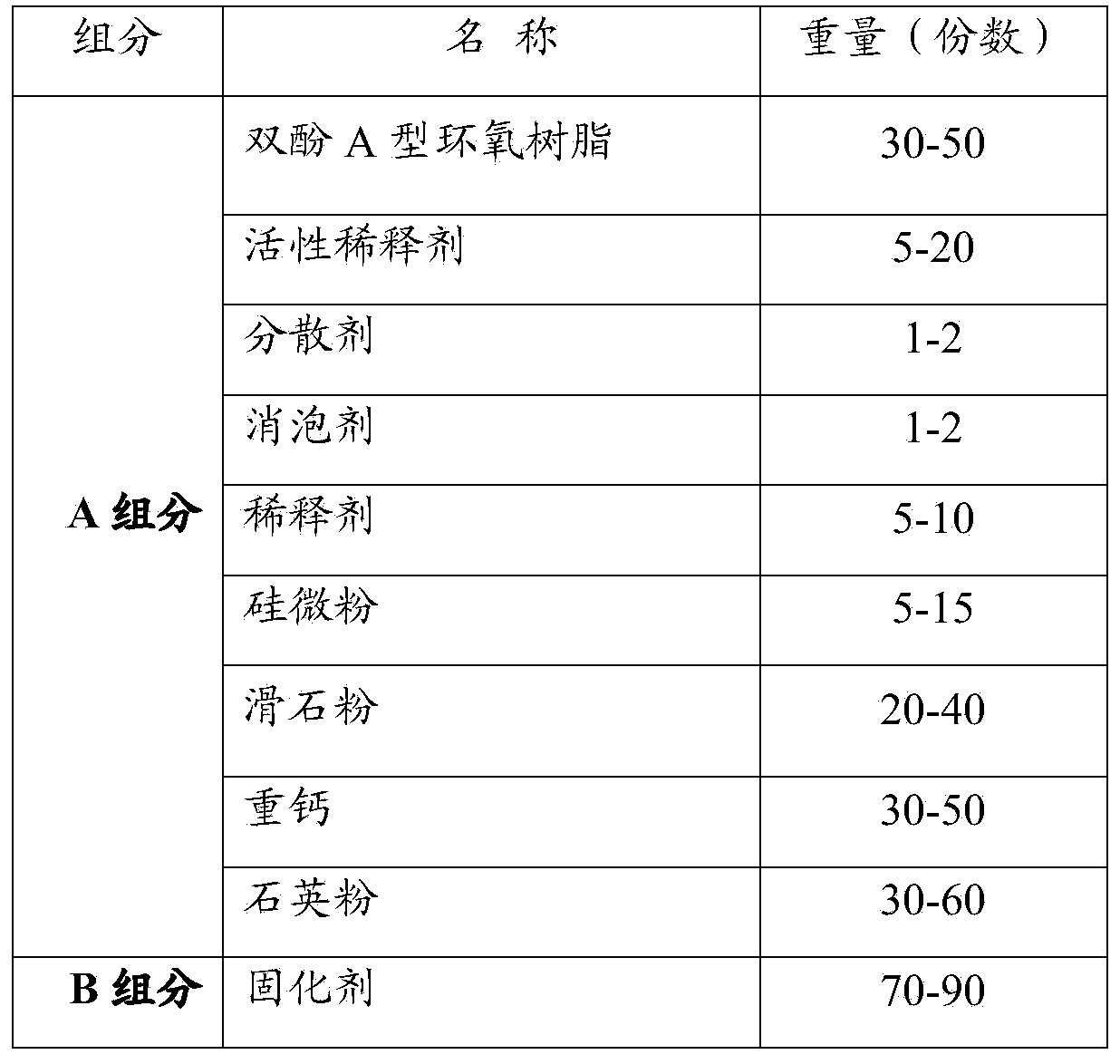

[0035] The preparation method of putty of the present invention comprises the following steps:

[0036] 1) Preparation of component A

[0037] Add bisphenol A type epoxy resin, reactive diluent, diluent, and additives into the mixing tank according to the weight ratio, and disperse at a high speed for 15-30 minutes in the mixing tank, and the speed is controlled at 500-800r / min; then add silicon micropowder, Talc powder, heavy calcium, quartz powder, after each filler is added and stirred for 10-15 minutes, the next filler can be added. After all the addition is complete, stir for 20-30 minutes to obtain component A;

[0038] 2) Preparation of component B

[0039] Add 2 parts of curing agent and curing accelerator into the stirring tank according to the weight ratio and stir evenly to obtain component B;

[0040] When in use, components A and B are mixed and stirred uniformly according to a specific ratio to obtain the putty.

Embodiment 1

[0043] A special putty for spraying polyurea elastomer of the present embodiment, its preparation method comprises the following two steps:

[0044] (1) Preparation of component A

[0045] According to the weight ratio, add 40 parts of E51 epoxy resin, 5 parts of AGE, 10 parts of diluent, 1 part of dispersant, and 1 part of defoamer into the mixing tank, stir for 15-30min, and control the speed at 500-800r / min ; Then add 5 parts of silicon micropowder, 20 parts of talc powder, 50 parts of heavy calcium and 40 parts of quartz powder in turn. After each filler is added and stirred for 10-15 minutes, the next filler can be added. After all the addition is complete, stir for 20-30 minutes to obtain component A.

[0046] (2) Preparation of component B

[0047] According to the weight ratio, add 85 parts of D400 and 15 parts of AEP into the mixing tank, and stir evenly to obtain component B.

[0048] When in use, mix evenly according to the ratio of A:B to 8:1 by weight, and the ...

Embodiment 2

[0054] A special putty for spraying polyurea elastomer of the present embodiment, its preparation method comprises the following two steps:

[0055] (1) Preparation of component A

[0056] According to the weight ratio, add 30 parts of E44 epoxy resin, 10 parts of BGE, 10 parts of diluent, 2.0 parts of dispersant, and 1.0 part of defoamer into the mixing tank, stir for 15-30min, and control the speed at 500-800r / min ; Then add 15 parts of silicon micropowder, 20 parts of talc powder, 40 parts of heavy calcium, and 60 parts of quartz powder in sequence. After each filler is added and stirred for 10-15 minutes, the next filler can be added. After all the addition is complete, stir for 20-30 minutes to obtain component A.

[0057] (2) Preparation of component B

[0058] According to the weight ratio, add 90 parts of D230 and 10 parts of AEP into the mixing tank, and stir evenly to obtain component B.

[0059] When using, mix evenly according to the weight ratio A:B of 10:1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com