Label fabric prepared from regenerative nylon grains

A technology of nylon particles and trademark cloth, which is applied in the field of trademark cloth, can solve the problems of the environmental protection of the substrate of the trademark tape and the overall preparation process to be improved, and achieve the effects of high refractive index, good compatibility and good heat reflection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

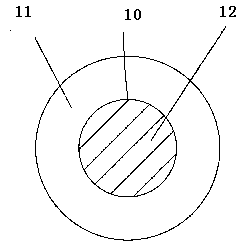

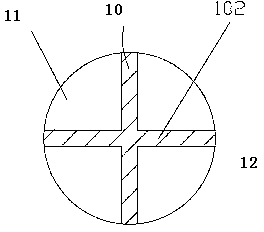

[0043] The regenerated nylon particle composition is PA66, and the spinning melting temperature of the regenerated nylon particle PA66 is 280°C; the yarn denier number after spinning is 30D.

[0044] Weaving of base fabric 1: single-strand yarns spun from regenerated nylon particles are used as warp yarns, with a density of 40 strands / cm; multi-strand synthetic fiber yarns are used as weft yarns; base fabric heat-setting finishing temperature is 120°C-160°C ℃. Heat setting adopts continuous section setting, specifically adopts the method of heating up and then cooling down. The continuous section shaping is specifically to use 8 ovens, the temperature is 120°C, 140°C, 160°C, 160°C, 160°C, 160°C, 150°C, 140°C, and the residence time in each oven is 10s.

[0045] In the glue layer 2 coated on the upper and lower sides of the base cloth 1, the rubber materials on both sides of the glue layer are the same, and the viscosity is 1200ps, and the composition is as follows in part...

Embodiment 2

[0055] The regenerated nylon particle composition is PA66, and the spinning melting temperature of the regenerated nylon particle PA66 is 330°C; the yarn denier number after spinning is 40D.

[0056] Weaving of base fabric 1: single-ply yarns spun from regenerated nylon particles are used as warp yarns with a density of 50 yarns / cm; multi-ply synthetic fiber yarns are used as weft yarns. Heat setting adopts continuous segmental shaping, specifically adopts the method of heating up and then cooling down, and the temperature is controlled at 120-160°C. The continuous section shaping is specifically to use 8 ovens, the temperature is 120°C, 140°C, 160°C, 160°C, 160°C, 160°C, 150°C, 140°C, and the residence time in each oven is 15s.

[0057]In the glue layer 2 coated on the upper and lower sides of the base cloth 1, the rubber materials on both sides of the glue layer are the same, and the viscosity is 1200-1800cps, which is composed of:

[0058] Methanol 60 parts

[0059] Calci...

Embodiment 3

[0067] The regenerated nylon particle composition is PA66, and the spinning melting temperature of the regenerated nylon particle PA66 is 300°C; the yarn denier number after spinning is 50D.

[0068] Weaving of the base fabric 1: the single-ply yarn spun from regenerated nylon particles is used as the warp yarn, and the density is 45 yarns / cm; the multi-ply synthetic fiber yarn is used as the weft yarn. Heat setting adopts continuous segmental shaping, specifically adopts the method of heating up and then cooling down, and the temperature is controlled at 120-160°C. The continuous section shaping is specifically to use 8 ovens, the temperature is 120°C, 140°C, 160°C, 160°C, 160°C, 160°C, 150°C, 140°C, and the residence time in each oven is 20s.

[0069] In the glue layer 2 coated on the upper and lower sides of the base cloth 1, the rubber materials on both sides of the glue layer are the same, and the viscosity is 1200-1800cps, which is composed of:

[0070] Methanol 50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com