A method for dyeing anionic dyes used in the production of two-layer organic tanned leather

An anionic dye and leather technology, applied in the field of leather processing technology, can solve the problems of inactivation, etc., and achieve the effect of good washability, good humidity and heat stability, uniform and rich color tone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

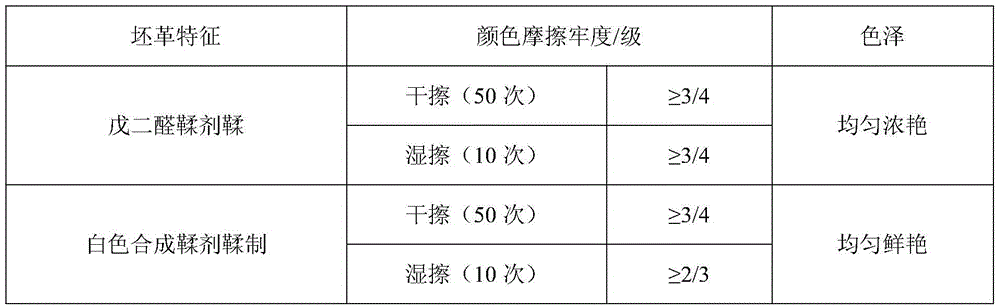

Image

Examples

Embodiment 1

[0018] Example 1 Pigskin two-layer brown shoe lining dyeing tanned with glutaraldehyde

[0019] After the tanning is completed, squeeze water, drop lightly for 10 minutes, cut it to a thickness of 1.0 mm, and weigh it as 100%.

[0020] Into the drum, wash with 150% normal temperature water for 10min, pH is ~ 6.0. Rinse with 0.2%~0.3% oxalic acid for 20min, measure pH to be 4.2~4.5, drain.

[0021] Add 60°C water into the drum to achieve a liquid ratio of 1.5, the internal temperature is 50°C, rotate for 10 minutes, and the pH of the bath solution is measured to be 4.3.

[0022] Add 4% sodium carboxymethyl cellulose, rotate for 30min; add 1% sodium perborate, rotate for 30min, drain; add 60℃ water into the drum, adjust the liquid ratio 1.5, inner temperature 50℃, add 2% direct dark brown (domestic commercial dyes), rotate for 30min, the dyeing rate is 90%. Add 6% sulfated vegetable oil and 6% synthetic oil (domestic commercial leather fatliquor), emulsification at 60°C) and ...

Embodiment 2

[0023] Example 2 Dyeing of two-layer gray glove leather of cowhide tanned with modified glutaraldehyde

[0024] After the tanning is completed, squeeze water, drop lightly for 10 minutes, shave evenly to a thickness of 0.8 mm, and weigh as 100%. Into the drum, wash with 150% normal temperature water for 10 min, pH is ~ 6.5. Rinse with 0.3% oxalic acid for 20min, measure pH to be 4.2, drain.

[0025] Add 60°C water into the drum to achieve a liquid ratio of 1.5, the internal temperature is 50°C, rotate for 10 minutes, and the pH of the bath solution is measured to be 4.1.

[0026] Add 4% soluble corn starch, rotate for 30min; add 1% cerium ammonium sulfate, rotate for 30min, drain; then add 60 ℃ water into the drum, adjust the liquid ratio 1.5, the inner temperature is 50 ℃, add 2% direct dark brown (domestic Commercial dyes), rotating for 30min, the dyeing rate is 90%. Add 6% sulfated vegetable oil and 6% synthetic oil (domestic commercial leather fatliquor), emulsify at 60...

Embodiment 3

[0027] Example 3 Dyeing of thin pigskin two-layer light black lining leather tanned with glutaraldehyde and white synthetic tanning agent

[0028] First tanned with glutaraldehyde, and then re-tanned with white synthetic tanning agent. After the tanning is completed, squeeze water, lightly drop for 10 minutes, shave evenly to a thickness of 1.0 mm, and weigh as 100%. Into the drum, wash with 150% normal temperature water for 10min, pH=3.8. Rinse with 0.2%~0.3% baking soda for 20min, measure pH to 4.2, drain.

[0029] Add 55°C water into the drum to achieve a liquid ratio of 1.5, the internal temperature is 45°C, rotate for 10 minutes, and the pH of the bath solution is measured to be 4.3.

[0030] Add 4% sodium carboxymethyl cellulose, rotate for 30min, add 1% sodium perborate, rotate for 30min, drain; add 55°C water into the drum, adjust the liquid ratio to 1.5, the inner temperature is 45°C, add 1% direct dark brown With 1% acid black dye (domestic commercial dye), rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com