Adhesive and application thereof in field of electrochromism

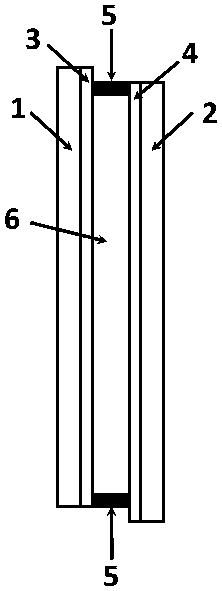

A technology of electrochromic devices and composite adhesives, applied in adhesives, instruments, optics, etc., can solve problems such as electrolyte leakage, poor stability of epoxy resin against moisture and heat, and failure of bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

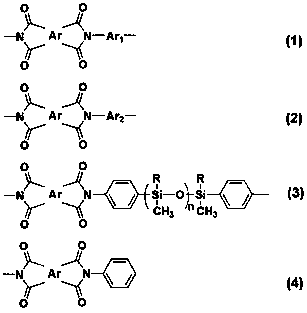

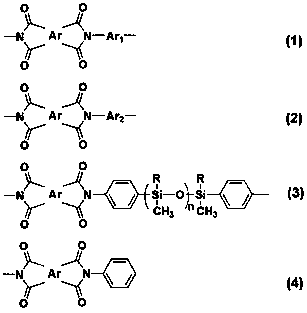

[0060] Preparation of polyimide-siloxane resin containing cyanate groups:

[0061] (1) Dissolve 3,3′,4,4′-diphenylsulfide tetracarboxylic anhydride (20mmol) in a mixed solvent of N,N-dimethylacetamide and tetrahydrofuran (volume 150mL, volume ratio 1 / 1), then add aminophenyl-terminated polydimethylsiloxane (2 mmol) with a molecular weight of 1995 g / mol, stir at room temperature for 3 hours, and extract tetrahydrofuran under reduced pressure;

[0062] (2) Add 4,4'-diaminodiphenyl ether (8.5mmol) and 3,5-bis(4-aminophenoxy)phenol (8.5mmol) to the solution obtained in step (1), and stir at room temperature for 5 hours ; Then add aniline (2mmol), stir at room temperature for 5 hours, then add water-carrying agent xylene (30 mL), and react at 180 ºC for 10 hours;

[0063] (3) Add cyanogen chloride (8.5 mmol) and triethylamine (10 mmol) to the solution obtained in step (2) under an ice-water bath, and react at room temperature for 1 hour;

[0064] (4) Add the solution obtained in...

Embodiment 2

[0069] Preparation of polyimide-siloxane resin containing cyanate groups:

[0070] (1) Dissolve 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl]hexafluoropropane dianhydride (20 mmol) in a mixture of N,N-dimethylformamide and tetrahydrofuran Solvent (150mL, volume ratio 2 / 1), then add aminophenyl-terminated polymethyltrifluoropropylsiloxane (3mmol) with a molecular weight of 2100g / mol, stir at room temperature for 5 hours, and extract tetrahydrofuran under reduced pressure;

[0071] (2) Add 4,4'-diaminodiphenyl ether (4mmol) and 3,5-bis(4-aminophenoxy)phenol (12mmol) to the solution obtained in step (1), and stir at room temperature for 5 hours; then Add aniline (2 mmol), stir at room temperature for 5 hours, then add water-carrying agent o-dichlorobenzene (40 mL), and react at 200 ºC for 5 hours;

[0072] (3) Add cyanogen chloride (12 mmol) and triethylamine (15 mmol) to the solution obtained in step (2) under an ice-water bath, and react at room temperature for 1 hour;

[0073] (4)...

Embodiment 3

[0078] Preparation of polyimide-siloxane resin containing cyanate groups:

[0079] (1) Dissolve 3,3′,4,4′-benzophenone tetracarboxylic anhydride (20mmol) in a mixed solvent of N-methylpyrrolidone and tetrahydrofuran (150mL, the volume ratio is 2 / 1), and then add the molecular weight 2100g / mol aminophenyl-terminated polymethyltrifluoropropylsiloxane (3mmol), after stirring at room temperature for 5 hours, extract tetrahydrofuran under reduced pressure;

[0080] (2) Add 3,3',5,5'-tetramethyl-4,4'-diaminodiphenylsulfide (8mmol) and 3,5-bis(4-amino Phenoxy)phenol (8mmol), stirred at room temperature for 5 hours; then added aniline (2mmol), stirred at room temperature for 5 hours, then added water-carrying agent xylene (30 mL), reacted at 180ºC for 10 hours;

[0081] (3) Add cyanogen chloride (8 mmol) and triethylamine (10 mmol) to the solution obtained in step (2) under an ice-water bath, and react at room temperature for 1 hour;

[0082] (4) Add the solution obtained in step (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com