Alignment type automatic de-molding ultraviolet nano impressing device and method

A technology of nanoimprinting and automatic demoulding, which is applied in the direction of optics, optomechanical equipment, instruments, etc., can solve the problems of small demoulding force, etc., and achieve the effects of reducing the generation of bubbles, less graphic replication defects, and easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the drawings and embodiments.

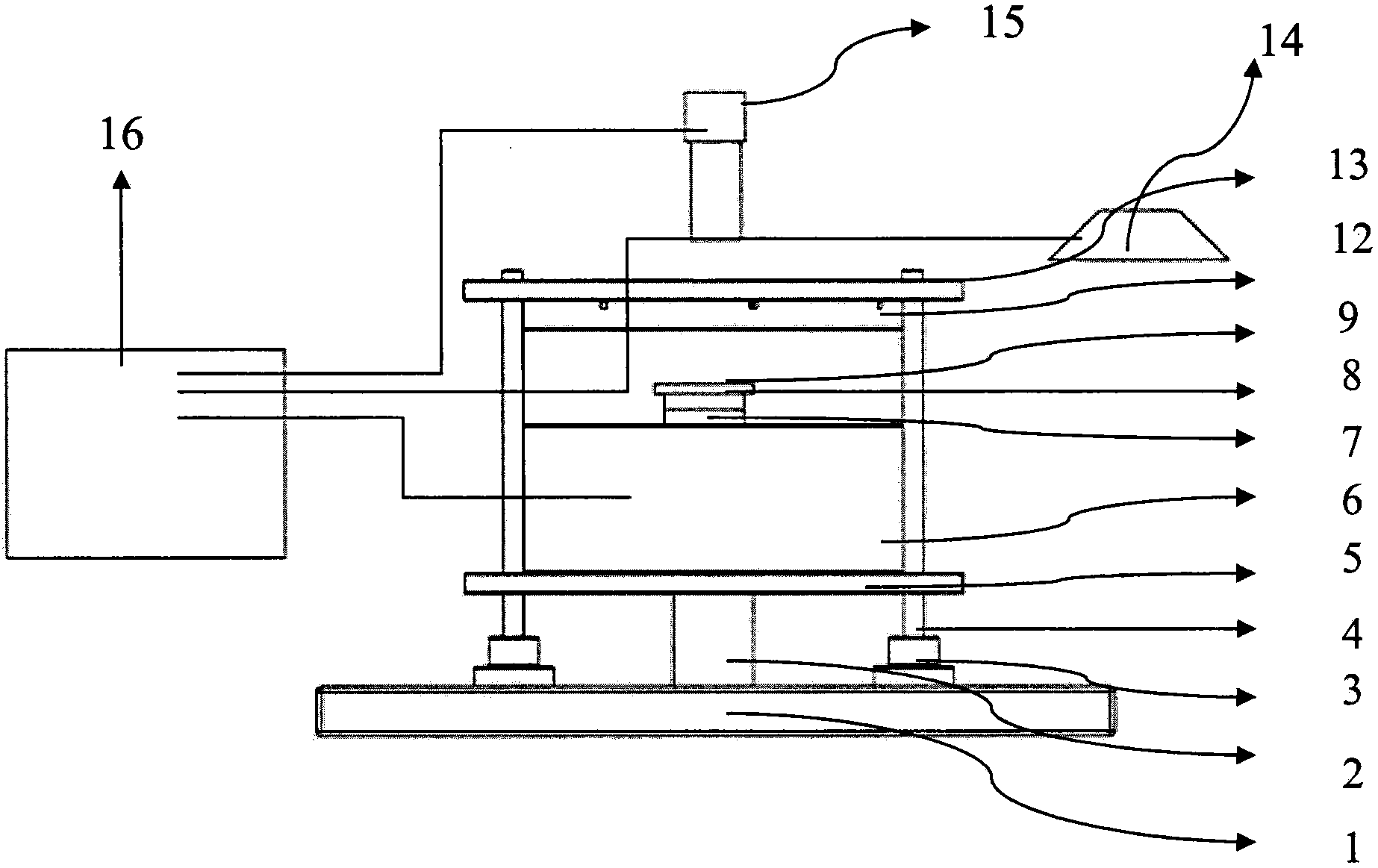

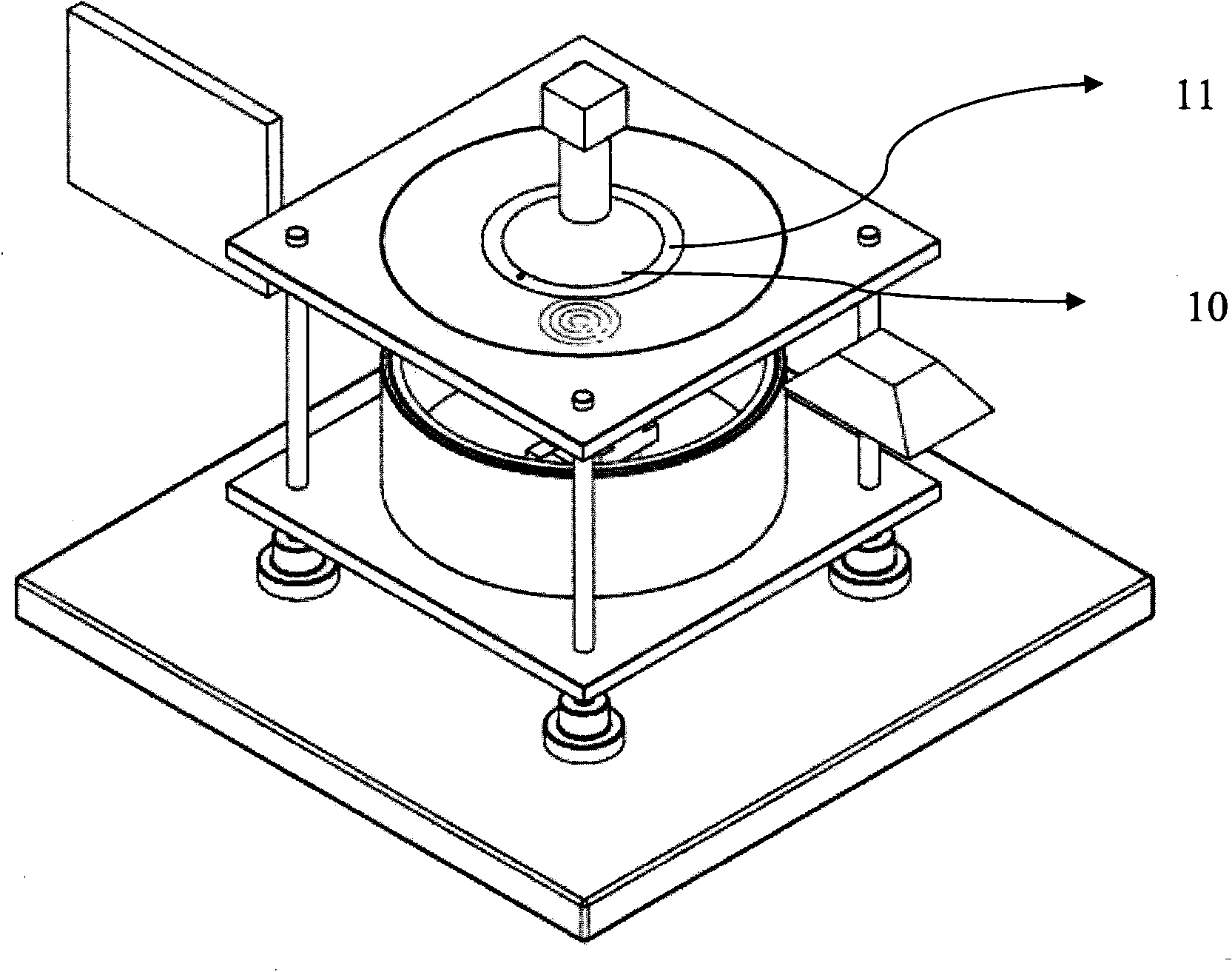

[0045] Such as Figure 1a-1b As shown, the embossing device of the present invention mainly includes: a marble shock absorber 1, a Z-axis platform 2, a directional guide rod base 3, a directional guide rod 4, a lower cavity fixed base plate 5, a lower cavity 6, an XYZT four-axis platform 7, a base Fixed platform 8, coated with anti-etching agent wafer 9, imprint template 10, imprint head 11, upper cavity 12, imprint head support base 13, ultraviolet light source 14, alignment mechanism 15, control System 16; wherein, the Z-axis platform 2 and the directional guide rod base 3 are fixed on the marble shock absorber 1, the guide rod 4 is connected to the directional guide rod base 3, and the other end of the Z-axis platform 2 is connected to the fixed bottom plate 5 of the lower chamber by the guide The rod 4 guides the Z axis, the XYZT four-axis platform 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com