Total station tunnel deformation remote monitoring system and establishing method thereof

A remote monitoring and deformation monitoring technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problem of inability to realize rapid and efficient sharing and release of information, limited selection of measuring instruments and improvement of accuracy, and construction interference Major problems, to achieve the effect of ensuring normal processing and release, short measurement time, and convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

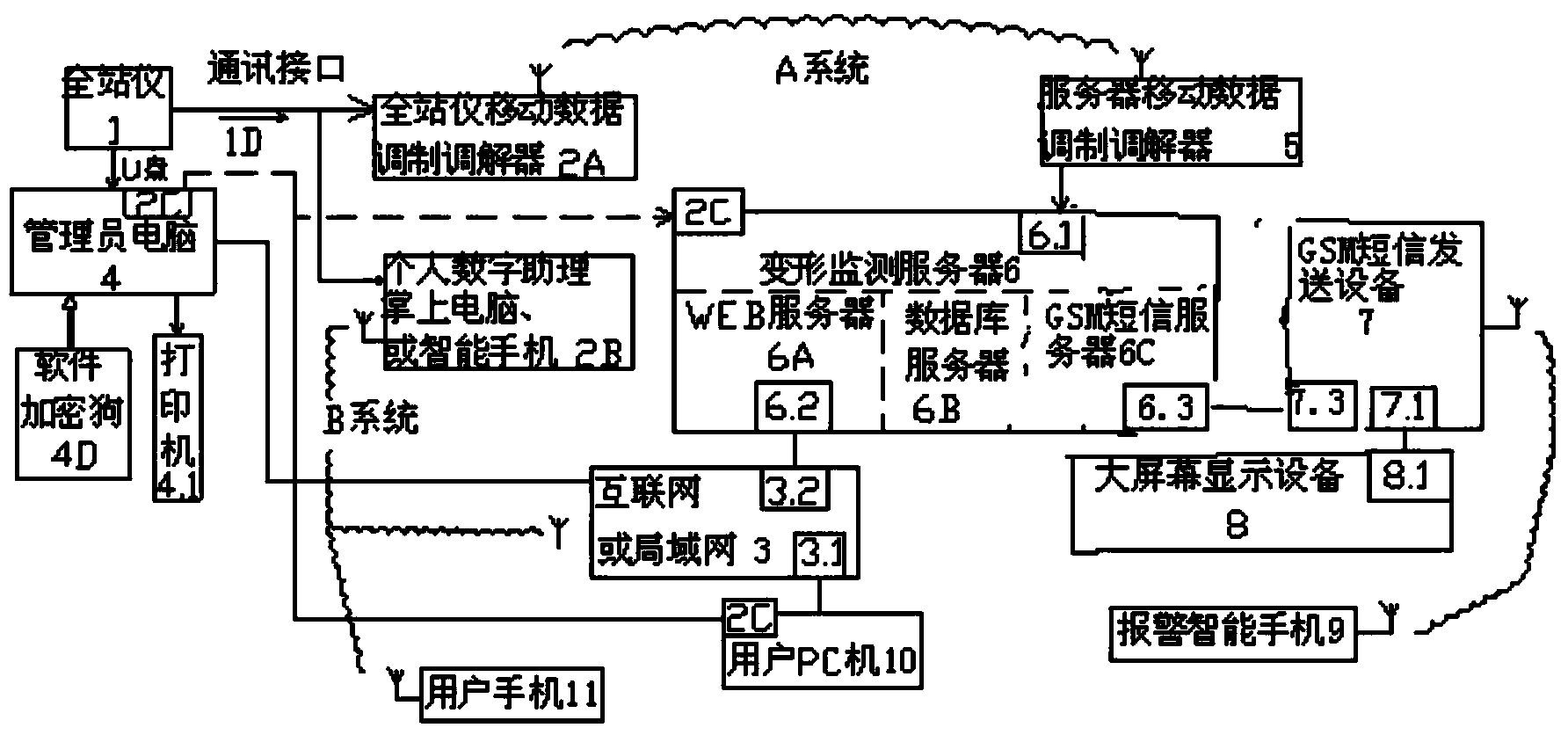

[0021] The total station tunnel deformation remote monitoring system of this embodiment includes the following parts:

[0022] 1) see figure 1 , The data acquisition part of this embodiment selects the high-precision automatic collimation total station 1. The total station is composed of power supply, angle measurement system, distance measurement system, data processing part, operating system, communication interface, display screen and keyboard. The existing total station is a commercially available product, and will not be described in detail here.

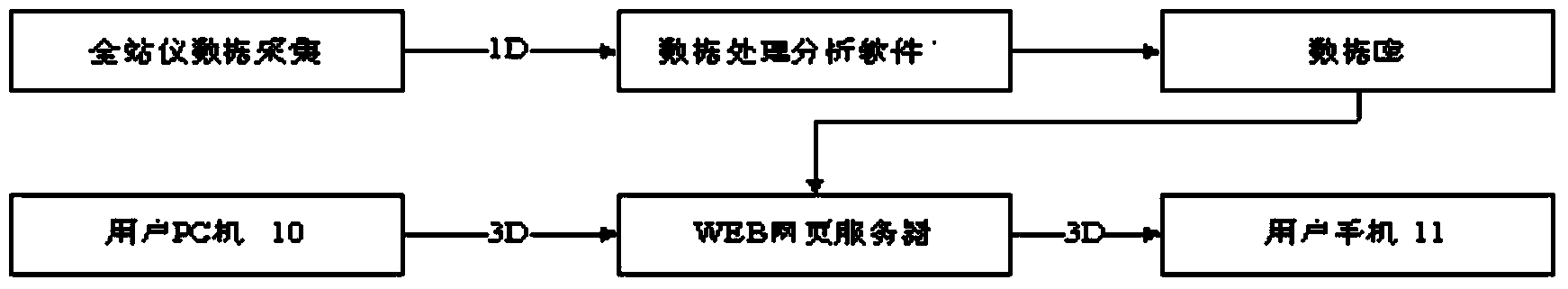

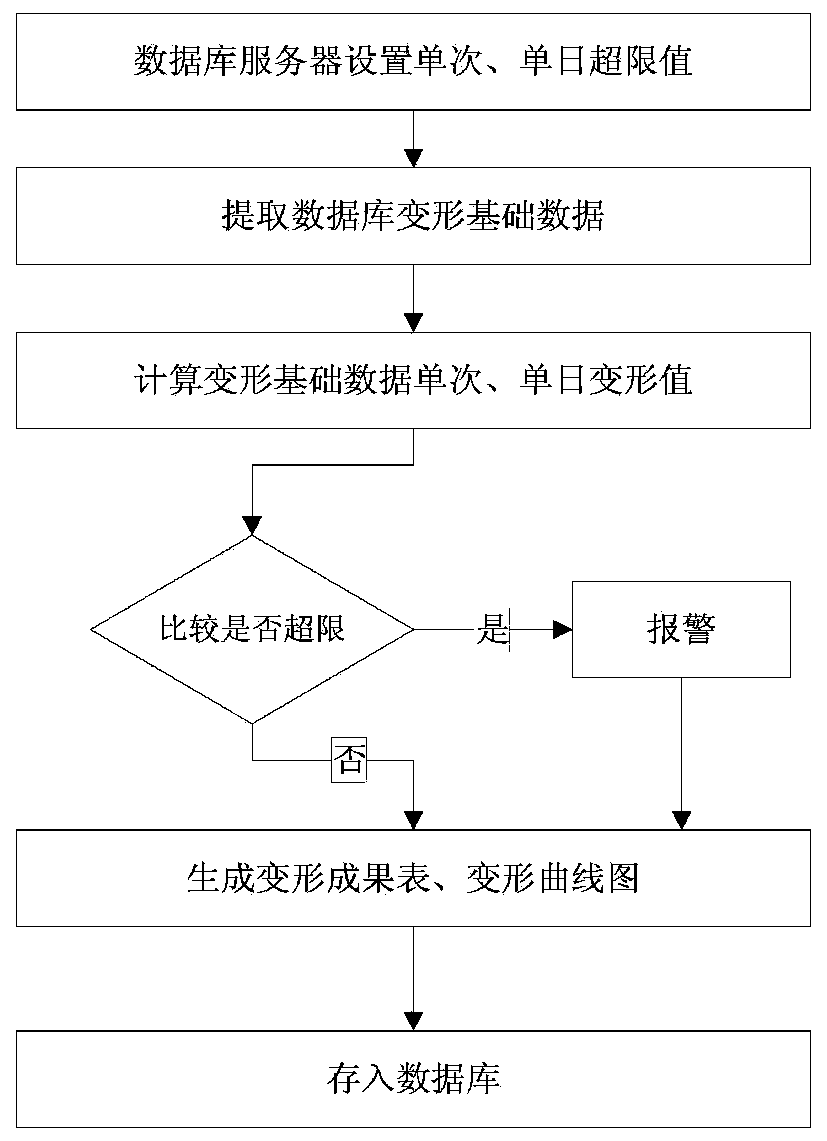

[0023] 2) see figure 1 , the present embodiment is provided with the mobile data modem 2A of the total station at the communication interface of the total station 1 for transmitting and collecting deformation basic data 1D, i.e. the GSM data MODEM, and it is wired with the communication interface. Present embodiment is provided with artificial intelligence mobile phone 2B and manual introduction system 2C simultaneously. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com