Organic light emitting diode panel and device and preparation, short-circuit detection and short-circuit reparation method of organic light emitting diode panel

A technology of organic light-emitting panel and organic light-emitting layer, which is applied in the direction of measuring device, circuit, measuring electricity, etc., can solve the problem of production line being polluted and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Such as Figure 2a-2dAs shown, the present invention discloses an organic light-emitting OLED panel, comprising: a substrate 10 ; and a plurality of adjacent light-emitting units located on the substrate 10 . In the figure, only two adjacent light emitting units are shown, that is, the first light emitting unit 11 and the second light emitting unit 22 , other light emitting units are not shown. The organic light-emitting OLED panel further includes a third electrode 31 located between adjacent light-emitting units (ie, the first light-emitting unit 11 and the second light-emitting unit 22 ). Of course, since only two adjacent light emitting units are shown in the figure, a third electrode may also be provided between the second light emitting unit and the adjacent light emitting unit (not shown in the figure). It also includes a connection wire M for connecting the first light emitting unit 11 and the second light emitting unit 22 .

[0072] refer to Figure 2d The f...

Embodiment 2

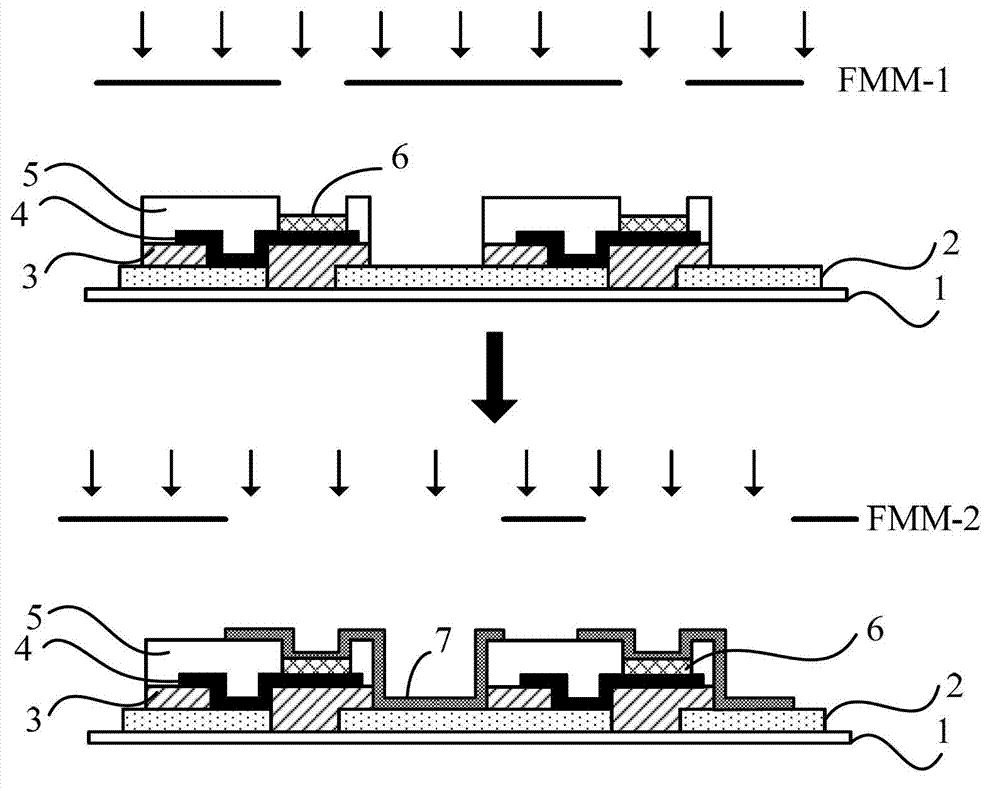

[0079] On the basis of the above-mentioned embodiments, Embodiment 2 of the present invention discloses a method for preparing an organic light-emitting OLED panel. The preparation process is as follows: Figure 2a-2d shown. Its specific preparation process is:

[0080] providing a substrate 10;

[0081] Such as Figure 2a , 2a’ As shown, a first conductive layer (not shown in the figure) is sequentially formed on the substrate 10, and the first conductive layer is patterned to form at least two adjacent first electrodes 120, 220 (in this embodiment, only two adjacent second electrodes as an example, but not limited thereto), the third electrode 31 located between the adjacent first electrodes 120, 220, and the third electrode 31 connected to one of the adjacent first electrodes 120, 220 The connection line M of the first electrode, the third electrode includes a first edge A1 extending from the bottom edge N of the third electrode 31;

[0082] Such as Figure 2b As show...

Embodiment 3

[0087] On the basis of the above embodiments, the present invention discloses another embodiment, such as Figures 3a-3e As shown, the present invention discloses an organic light-emitting OLED panel, including: a substrate 110 ; and a plurality of adjacent light-emitting units located on the substrate 110 . In the figure, only two adjacent light-emitting units, ie, the first light-emitting unit 101 and the second light-emitting unit 201 , are shown, and other light-emitting units are not shown. The organic light-emitting OLED panel further includes a third electrode 112 located between adjacent light-emitting units (ie, the first light-emitting unit 101 and the second light-emitting unit 201 ). Of course, since only two adjacent light emitting units are shown in the figure, a third electrode 212 may also be provided between the second light emitting unit and the adjacent light emitting unit (not shown in the figure).

[0088] Wherein the first light-emitting unit 101 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com