LED epitaxial layer, growth method thereof and LED chip

A technology of LED chip and growth method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low luminous efficiency of LED chips, achieve the effects of inhibiting lateral growth, improving luminous efficiency, and increasing the number of quantum dots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

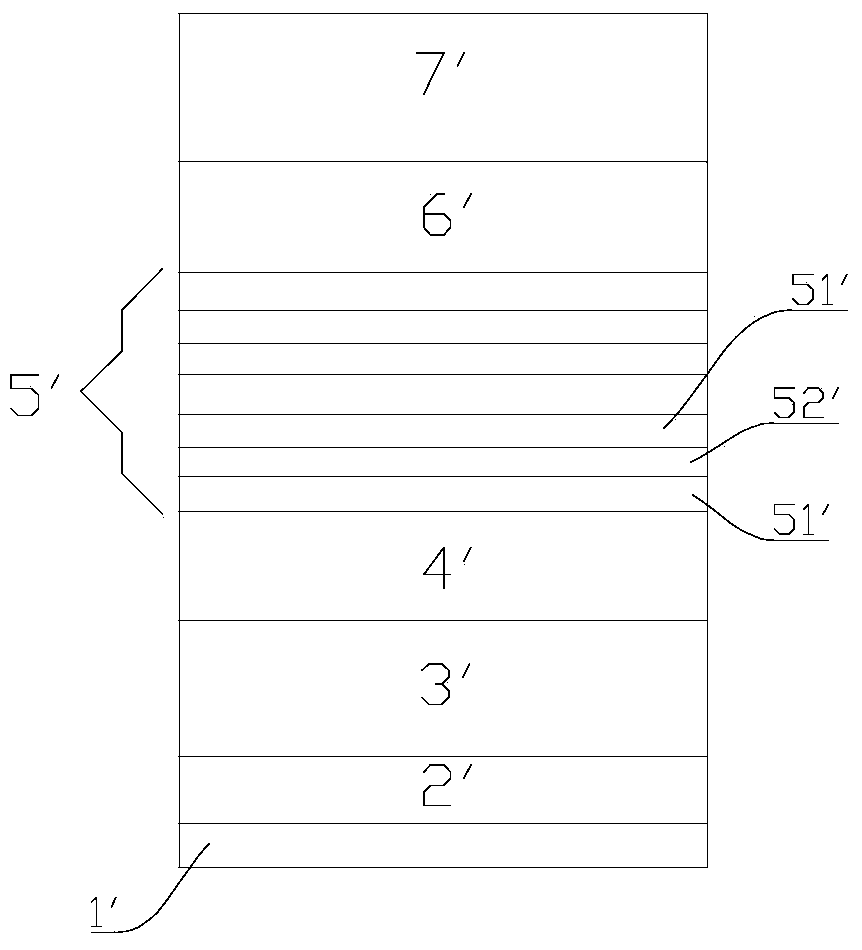

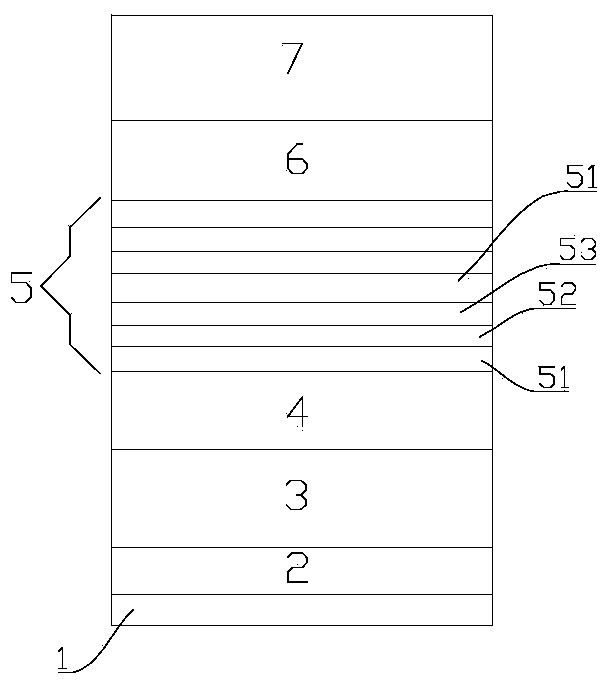

[0032] The LED epitaxial layer of example 2 is as image 3 shown. The difference between Example 2 and Example 1 is that a unit structure of the MQW layer 5 is a Mg-doped layer 53 disposed on the top surface of the N-type confinement layer 4 . The InGaN layer 51 is disposed on the top surface of the Mg-doped layer 53 . GaN layer 52 is provided on the top surface of InGaN layer 51 .

example 3

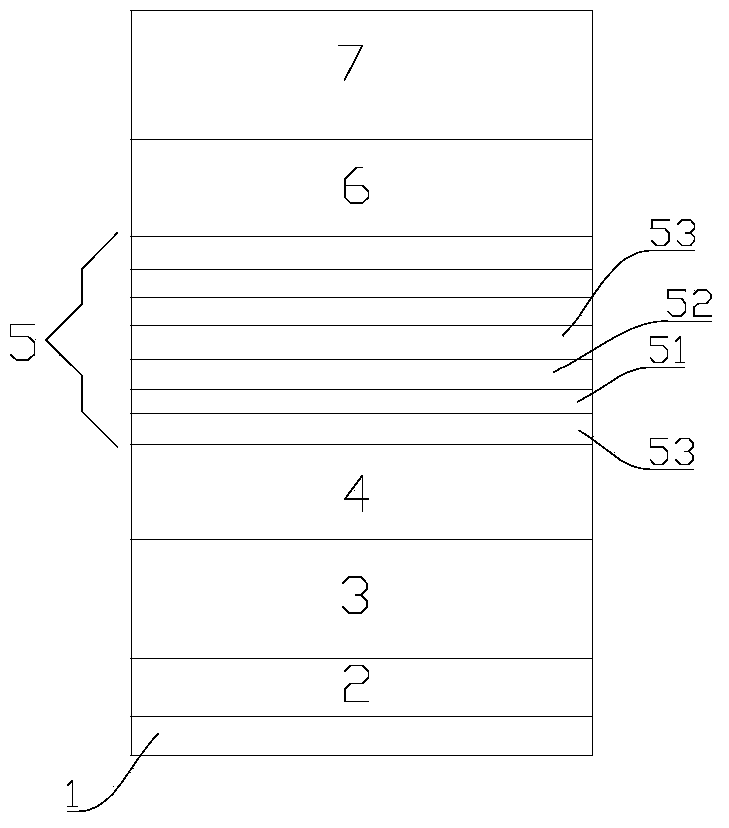

[0033] The LED epitaxial layer of example 3 is as Figure 4shown. The difference between Example 3 and Example 1 is that a unit structure of the MQW layer 5 is an InGaN layer 51 disposed on the top surface of the N-type confinement layer 4 . A magnesium-doped layer 53 is provided on the top surface of the InGaN layer 51 . GaN layer 52 is disposed on top of magnesium-doped layer 53 .

[0034] Most preferably, the magnesium-doped layer 53 in the structural unit is grown on the top surface of the N-type confinement layer 4 , the InGaN layer 51 is grown on the top surface of the magnesium-doped layer 53 , and the GaN layer 52 is grown on the top surface of the InGaN layer 51 . At this time, the luminous efficiency of the LED epitaxial layer increases the most.

[0035] The structures mentioned in Examples 1-3 can increase the number of quantum dots in the InGaN layer 51 when growing it, thereby improving the luminous efficiency of the LED epitaxial layer. Each layer outside th...

Embodiment 1

[0063] 1. Process the sapphire substrate for 17 minutes at 1100°C and maintain the reaction chamber pressure at 200mbar in a hydrogen atmosphere;

[0064] 2. Cool down to 550°C, keep the pressure in the reaction chamber at 300mbar, and feed NH at the same time 3 , TMGa grows a buffer GaN layer 2 with a thickness of 30 nm on the sapphire substrate 1;

[0065] 3. Raise the temperature to 1100°C, maintain the pressure in the reaction chamber at 200mbar, and feed NH at the same time 3 , TMGa, growing a 2 μm undoped GaN layer 3;

[0066] 4. Then feed NH at the same time 3 , TMGa, SiH 4 N-type GaN doped with Si is grown, the Si doping concentration is 1E+19, and the total thickness is controlled at 2-4 μm to obtain an N-type confinement layer 4;

[0067] 5. The pressure of the reaction chamber is maintained at 300mbar, and Cp2Mg and NH are introduced at the same time 3 MgN crystal nuclei with a thickness of 1.0 nm are grown for 50 seconds to obtain a magnesium-doped layer 53 ; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com