Absorbable skin suturing nail and preparation method thereof

A suture nail and skin technology, applied in the field of medical equipment, can solve the problems of low tissue healing quality, poor dimensional stability under force, material disintegration, etc., and achieve good melt rheological properties, good dimensional stability, and good processing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0023] In the first embodiment of the absorbable skin staples of the present invention, the material of the absorbable skin staples is a random copolymer of L-lactide (left-handed lactide) and glycolide, in the random copolymer The molar content of L-lactide is 50%-70%, and the molar content of glycolide is 30%-50%.

[0024] The intrinsic viscosity of the random copolymer (measured at 30°C with 0.1% hexafluoroisopropanol as a solvent, the same below) is 1.2-2.0dl / g, and the residual monomer content is not more than 1% , the moisture content is less than 500ppm (parts permillion, a part per million, 500ppm is five hundred millionths). The random copolymer has good melt rheological properties and is easy to process.

[0025] Regarding the intrinsic viscosity of the random copolymer, when the intrinsic viscosity of this type of random copolymer material is lower than 1.0dl / g, the processability is poor, and the mechanical strength of the absorbable skin staple product obtained b...

no. 2 example

[0030] In the second embodiment of the absorbable skin staples of the present invention, the material of the absorbable skin staples is a random copolymer of L-lactide and glycolide, and the L-lactide in the random copolymer The molar content is preferably 51%, and the molar content of glycolide is preferably 49%. The intrinsic viscosity of the random copolymer (intrinsic viscosity is measured at 30°C with 0.1% hexafluoroisopropanol as a solvent, the same below) is preferably 1.25dl / g, and the residual monomer content is preferably 0.65%, The moisture content is preferably 255 ppm.

[0031] The random copolymer of L-lactide and glycolide is used as raw material to make absorbable skin suture staples through injection molding process. The specific parameters of injection molding process are: feed section temperature 155°C, melting section temperature 170°C, The temperature is 160°C and the injection pressure is 45bar.

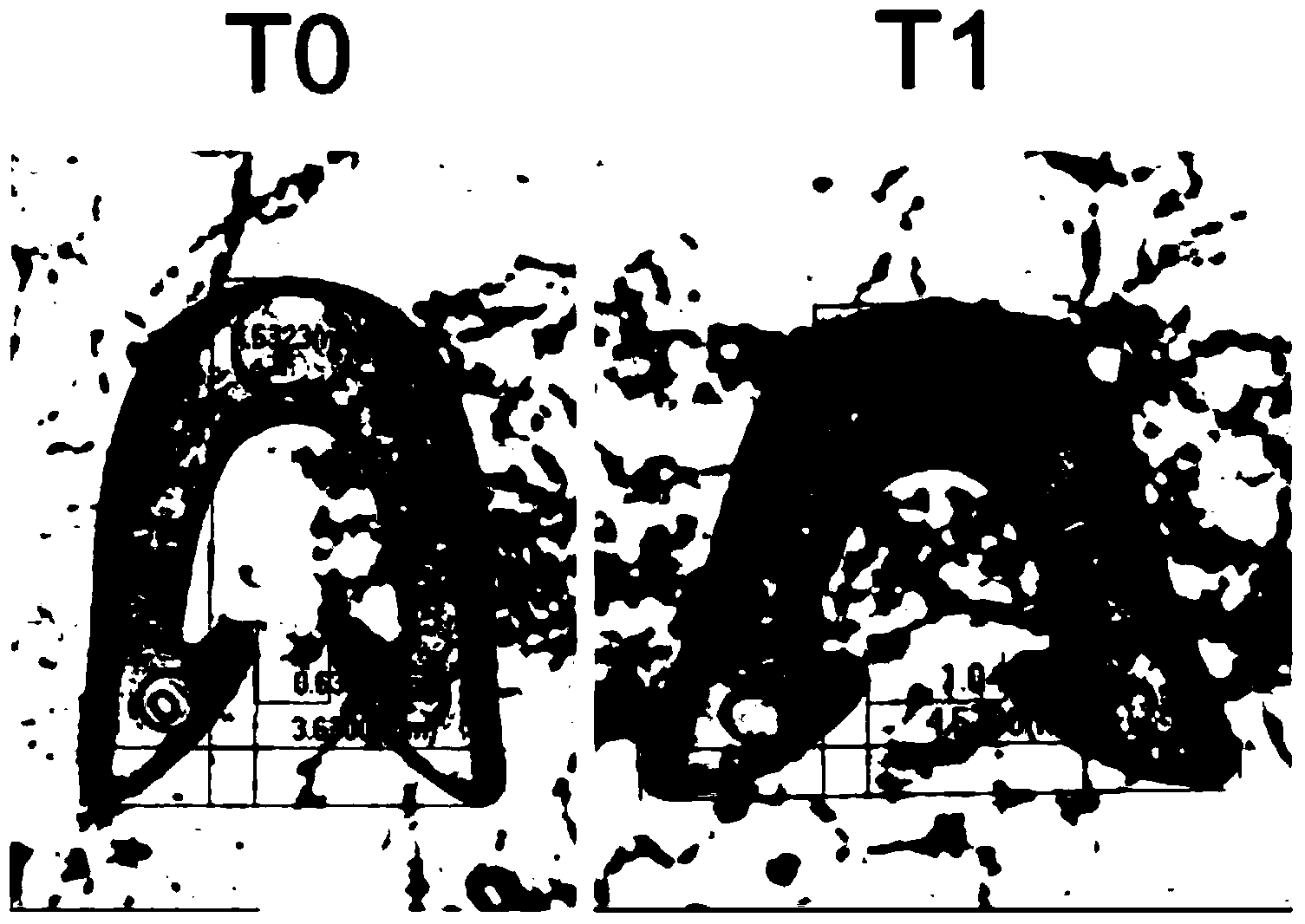

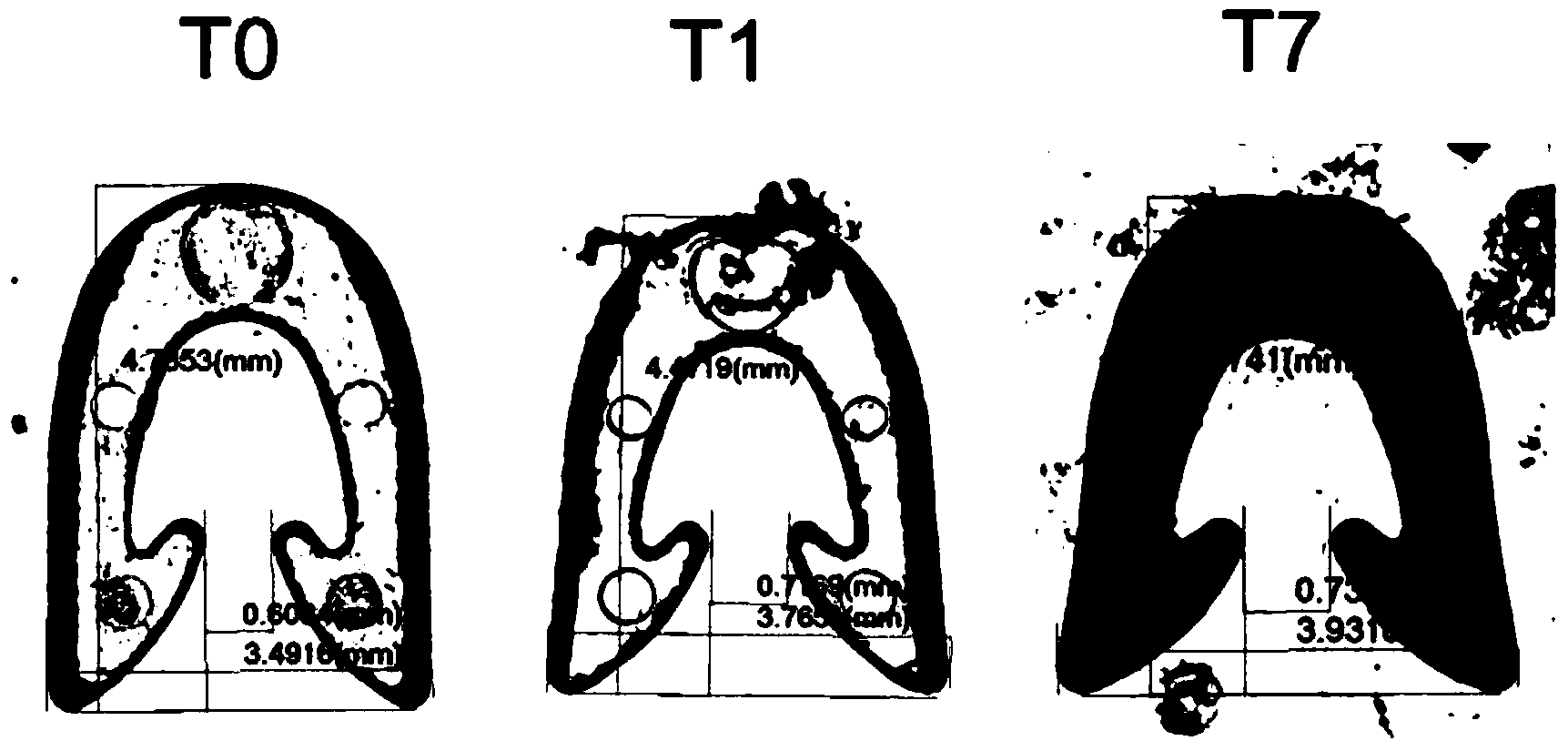

[0032]The absorbable skin staples after the injection mo...

no. 3 example

[0034] In the third embodiment of the absorbable skin staple of the present invention, the material of the absorbable skin staple is a random copolymer of L-lactide and glycolide, and the L-lactide in the random copolymer The molar content is preferably 60%, and the molar content of glycolide is preferably 40%. The intrinsic viscosity of the random copolymer (intrinsic viscosity is measured at 30°C with 0.1% hexafluoroisopropanol as a solvent, the same below) is preferably 1.40dl / g, and the residual monomer content is preferably 0.50%, The moisture content is preferably 350 ppm.

[0035] The random copolymer of L-lactide and glycolide is used as raw material to produce absorbable skin suture staples through injection molding process. The specific parameters of injection molding process are: feed section temperature 160°C, melting section temperature 175°C, The temperature is 165°C and the injection pressure is 55bar.

[0036] After the injection molding process, the absorbab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com