Sunflower pollen separating machine

A separator, pollen technology, applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

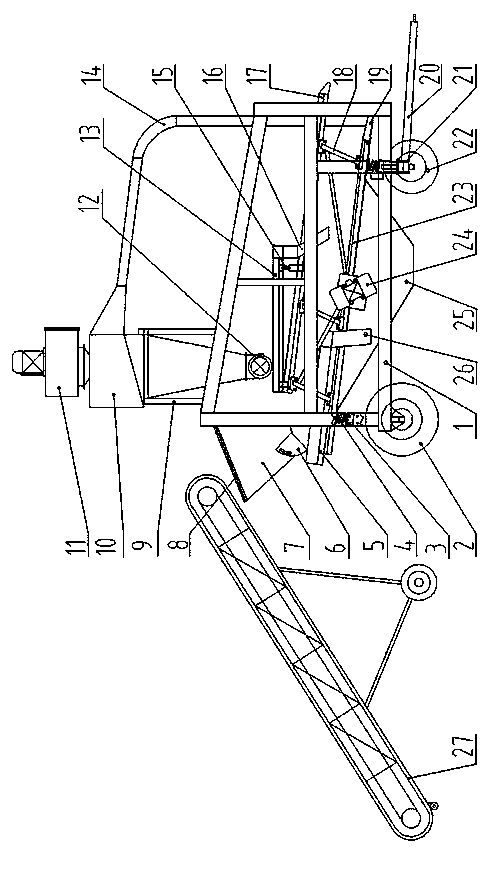

[0007] In the present invention, support rear wheels 2 are respectively installed at both ends of the bottom of the frame 1; a storage box 7 corresponding to a conveying feeder 27 is installed on the frame 1, and a reinforcement screen 8 is installed at the feed inlet of the storage box 7 A blanking adjustment door 6 is installed at the outlet of the material storage box 7; a lower rotary drum blanker 10 is installed on the top of the frame 1 through a bracket 9; a low pressure lifting fan 11 is installed at the air outlet of the lower rotary drum blanker 10 , and a spiral discharge mechanism 12 is installed at the outlet of the lower rotary drum blanker 10, and a fan lifting suction pipe 14 is installed at the feed port of the lower rotary drum blanker 10; The primary screening support of spring 4 is installed, and supporting primary screening 23 is installed on the primary screening support, and supporting primary screening 23 ends is equipped with filtering screen 5, and fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com