Electro-gas welding technology suitable for thick plates with thickness ranging from 20 mm to 45 mm

A gas-electric vertical welding and thick plate technology, which is applied to arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of difficult adaptation and matching, high cost, and complicated preparation work, so as to ensure the mechanical properties of the weld seam and save energy. Welding cost, better weld seam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

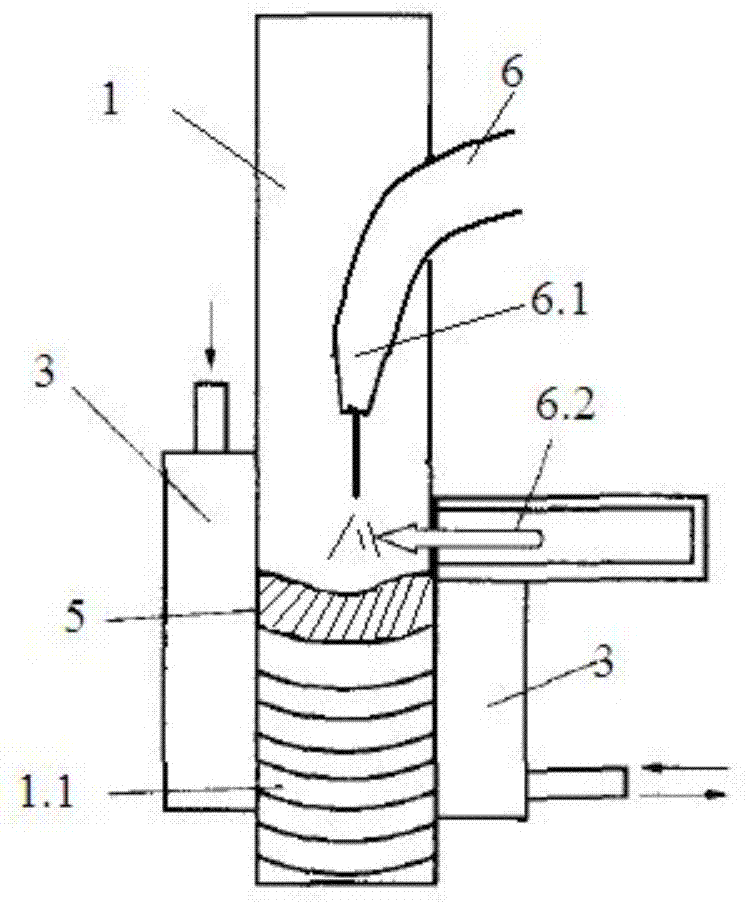

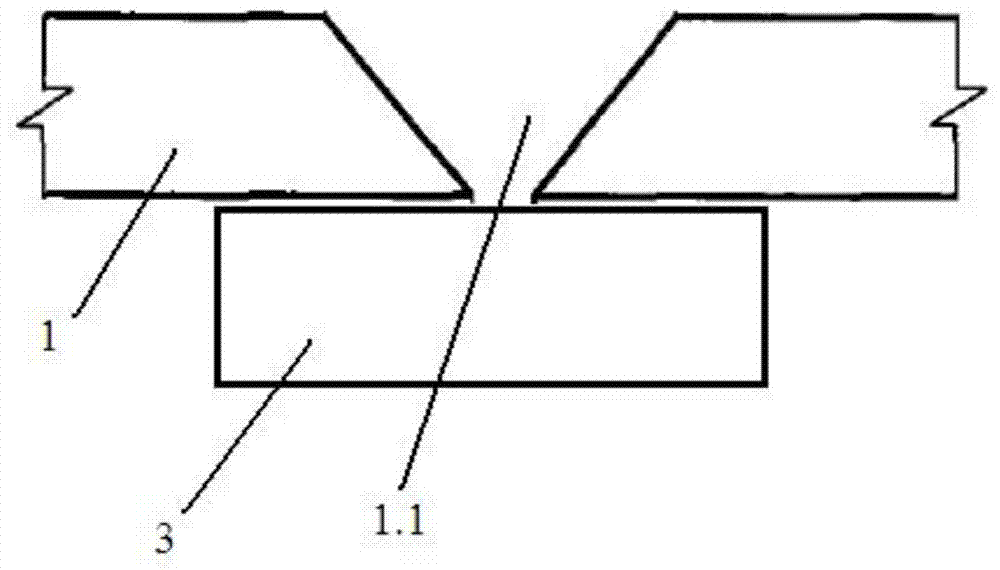

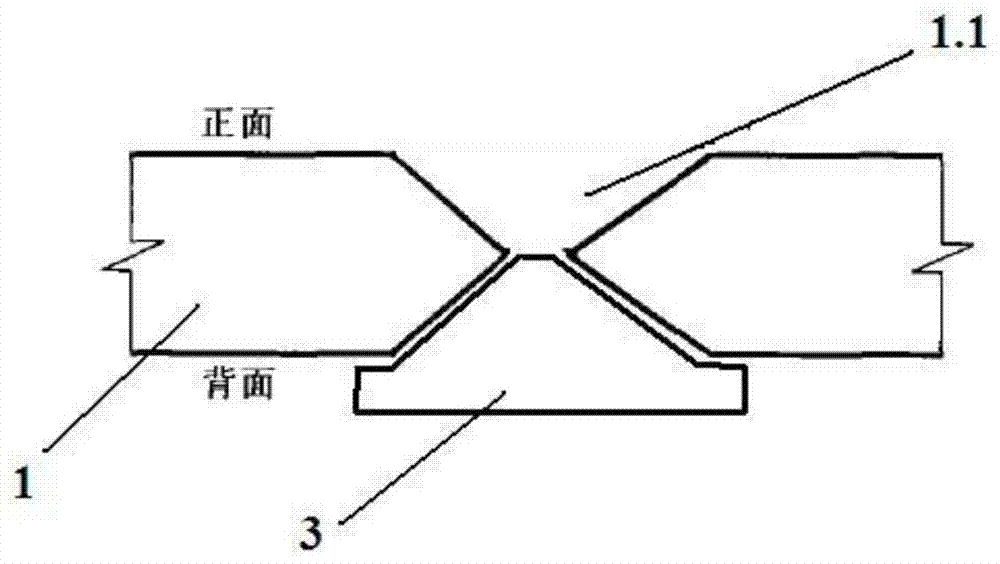

[0029] Figure 1~3 It is a schematic diagram of the traditional gas-electric vertical welding process, and its structure has been discussed above, so it will not be repeated here.

[0030] Such as Figure 4~6 As shown, the gas-electric vertical welding process suitable for 20~45mm thick plates designed by the present invention comprises the following steps:

[0031] 1) First process sub-grooves on the front sides of the two thick plates 1 to be welded, and assemble the two thick plates 1 to be welded together according to the weld seam requirements, so that the sub-grooves on the front sides of the two thick plates 1 to be welded Combined to form trapezoidal front groove 2;

[0032] 2) Since there is no groove processed on the reverse side, it can play a role in forcing the welding liquid to form. If necessary, a cooling block 3 ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com