A kind of ultra-low hydrogen ceramic flux for chromium-molybdenum heat-resistant steel and its preparation method

A ceramic flux and heat-resistant steel technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of low diffusible hydrogen content, flux absorption, etc., to achieve optimized high-speed welding, arc stability, Good slag removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

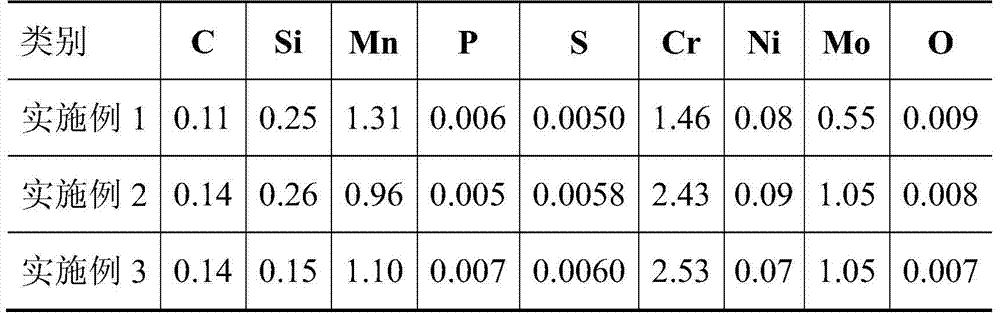

[0038] The specific composition of ceramic flux components is shown in Table 1.

[0039] Table 1 Example composition ratio (wt%)

[0040] serial number Example 1 Example 2 Example 3 MgO 28% 35% 32% CaF 2

22% 17% 20% al 2 o 3

20% 13% 19% CaO 11% 8% 10% SiO 2

10% 9% 5% K 2 O+NaO

1% 5% 3.5% Si-Fe 0.5% 1.5% 2% Mn-Fe 0.5% 3.5% 2.5% MgCO 3

7% 8% 6%

[0041] This flux has excellent weld process performance, stable arc during welding, bright white and non-oxidized surface of the weld, good slag removal in the groove, the slag removal rate of the bottom layer after vibration reaches more than 75%, and the slag in the groove automatically lifts up, just ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com