Method for oxidizing industrial wastewater with oxydol by using marmatite as catalyst

A technology for sphalerite and industrial wastewater, which is applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of affecting the effluent color and its reuse, difficult to treat iron-containing sludge, and narrow pH value range, etc. Utilization efficiency, easy recycling, and the effect of applying a wide pH range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

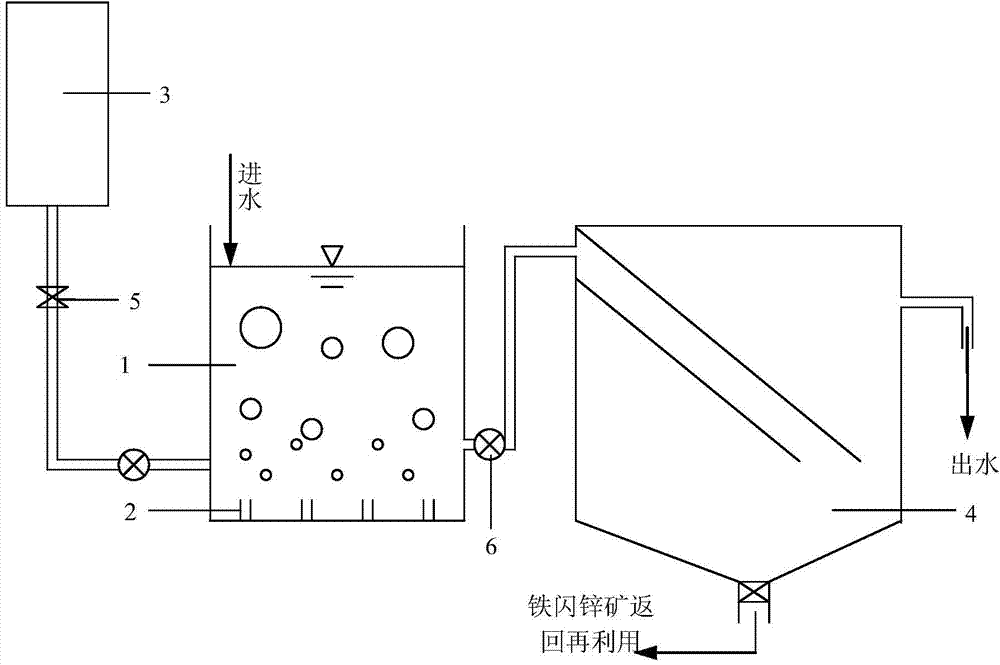

Embodiment 1

[0056] Add sphalerite enriched by flotation, magnetic separation and pickling into a 2.5m×2m×1.5m reaction tank filled with printing and dyeing wastewater biochemical effluent (secondary effluent, COD93mg / L), and sphalerite The dosage is 2.5g / L. After mixing evenly, adjust the pH value of the wastewater to 3-5, and then pump H from the hydrogen peroxide storage tank 2 o 2 , the dosage is 135mg / L, and the aeration device at the bottom of the reaction tank is turned on, so that the sphalerite is in a suspended state in the reaction tank. After 30 minutes of reaction, the sphalerite and water were separated by a solid-liquid separation device, the COD and TOC values of the effluent were measured, and the COD and TOC removal rates were calculated. The results show that the biochemical effluent of printing and dyeing wastewater treated with sphalerite has a COD removal rate of up to 87.3%, and a TOC removal rate of up to 75.6%, which is 16.1 percentage points higher than the tr...

Embodiment 2

[0058] Add sphalerite enriched by flotation, magnetic separation and pickling into a 2.5m×2m×1.5m reaction tank filled with dye wastewater biochemical effluent (secondary effluent, COD186mg / L), and sphalerite The dosage is 3g / L. After mixing evenly, adjust the pH value to 2, 3, 5, 7, 9 respectively, pump in H 2 o 2 , the dosage is 270mg / L, open the aeration device at the bottom of the reaction tank to react for 120min, measure the COD and TOC values of the oxidation reaction effluent of the solid-liquid separation device, and calculate the COD and TOC removal rates. The COD removal rates corresponding to pH values of 2, 3, 5, 7, and 9 were 87.3%, 91.8%, 85.3%, 85.7%, and 80.3%, respectively, and the TOC removal rates were 78.4%, 75.5%, 72.6%, and 73.3%, 70.8%. It can be seen that the change of pH value has little effect on the treatment effect. This shows that sphalerite as a catalyst has a good adaptability to the pH of the biochemical effluent of dye wastewater. Aft...

Embodiment 3

[0060] Add sphalerite after flotation, magnetic separation enrichment and pickling into a 2.5m×2m×1.5m reaction tank filled with coking wastewater biochemical effluent (COD150mg / L), and the sphalerite dosage is 2g / L. After mixing evenly, adjust the pH value to 5~6 respectively, pump in H 2 o 2 , the dosage is 230mg / L, and the aeration device at the bottom of the reaction tank is turned on for the reaction. After 60 minutes of reaction, the sphalerite and water are separated by the solid-liquid separation device, the COD and TOC values of the effluent are measured, and the removal of COD and TOC is calculated. Rate. COD removal rate is 86.8%, TOC removal rate is 71.4%. After the sphalerite was reused 10 times, the COD removal rate of the effluent was still above 83%, and the TOC removal rate was about 70%, indicating that the sphalerite as a catalyst can be recovered and reused many times, and the catalytic activity is still high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com