Aspergillus niger lipase and its preparation method

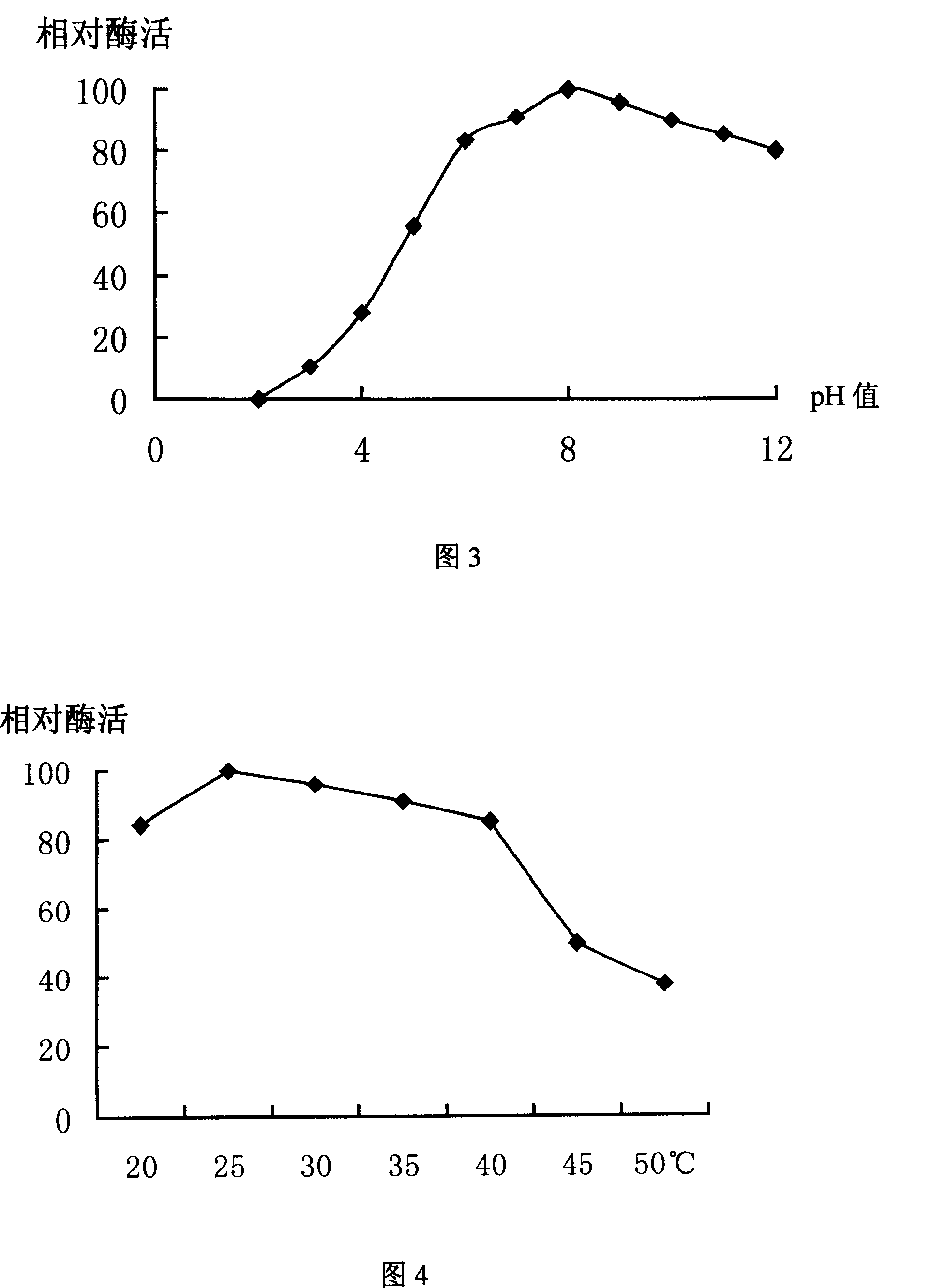

A technology of Aspergillus niger and lipase, applied in the field of lipase and its preparation, can solve the problems of narrow pH value range and instability of Aspergillus niger lipase, and achieve the effects of wide applicable pH value range, wide application and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

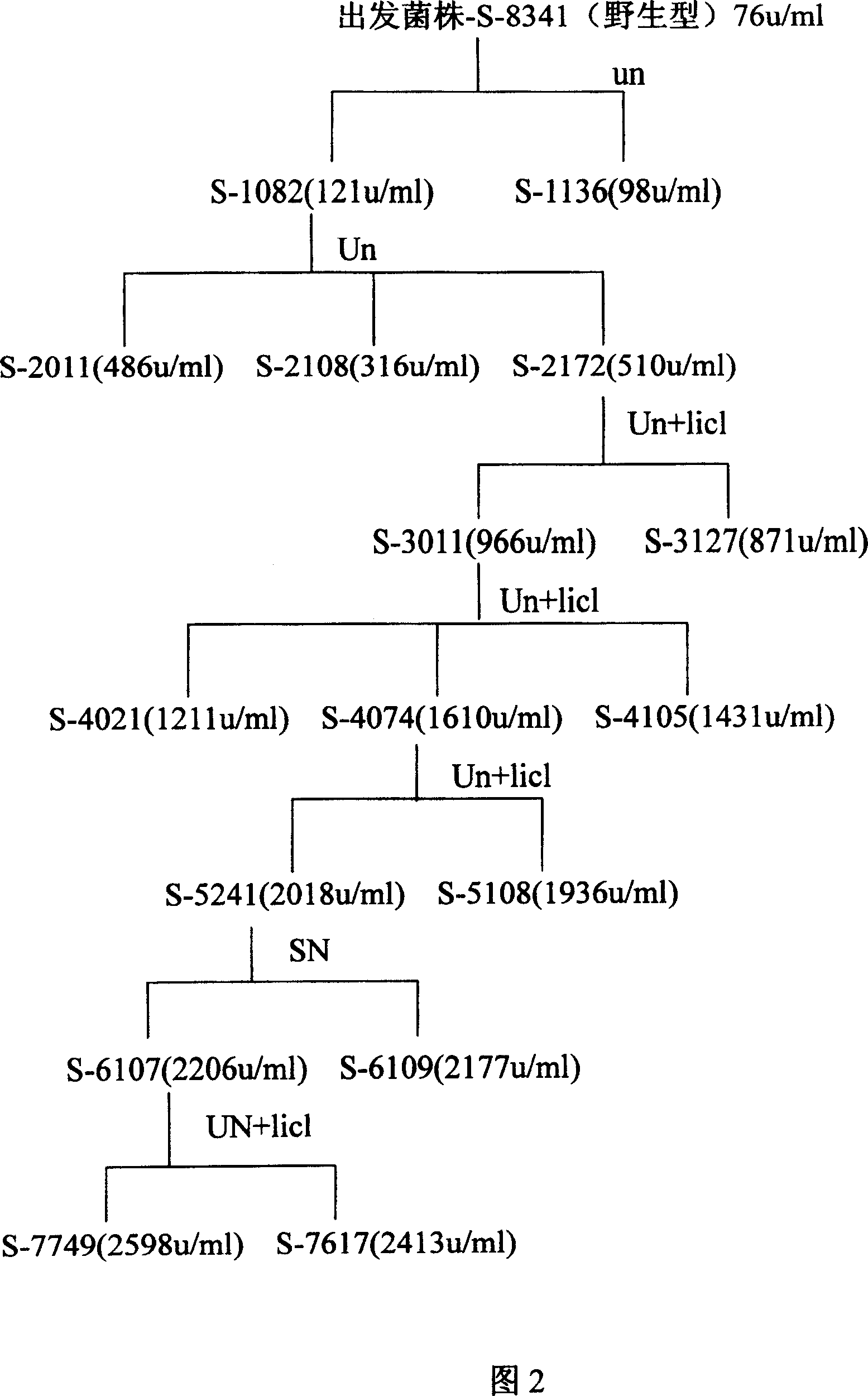

[0022] Strain: Aspergillus niger strain S-7749

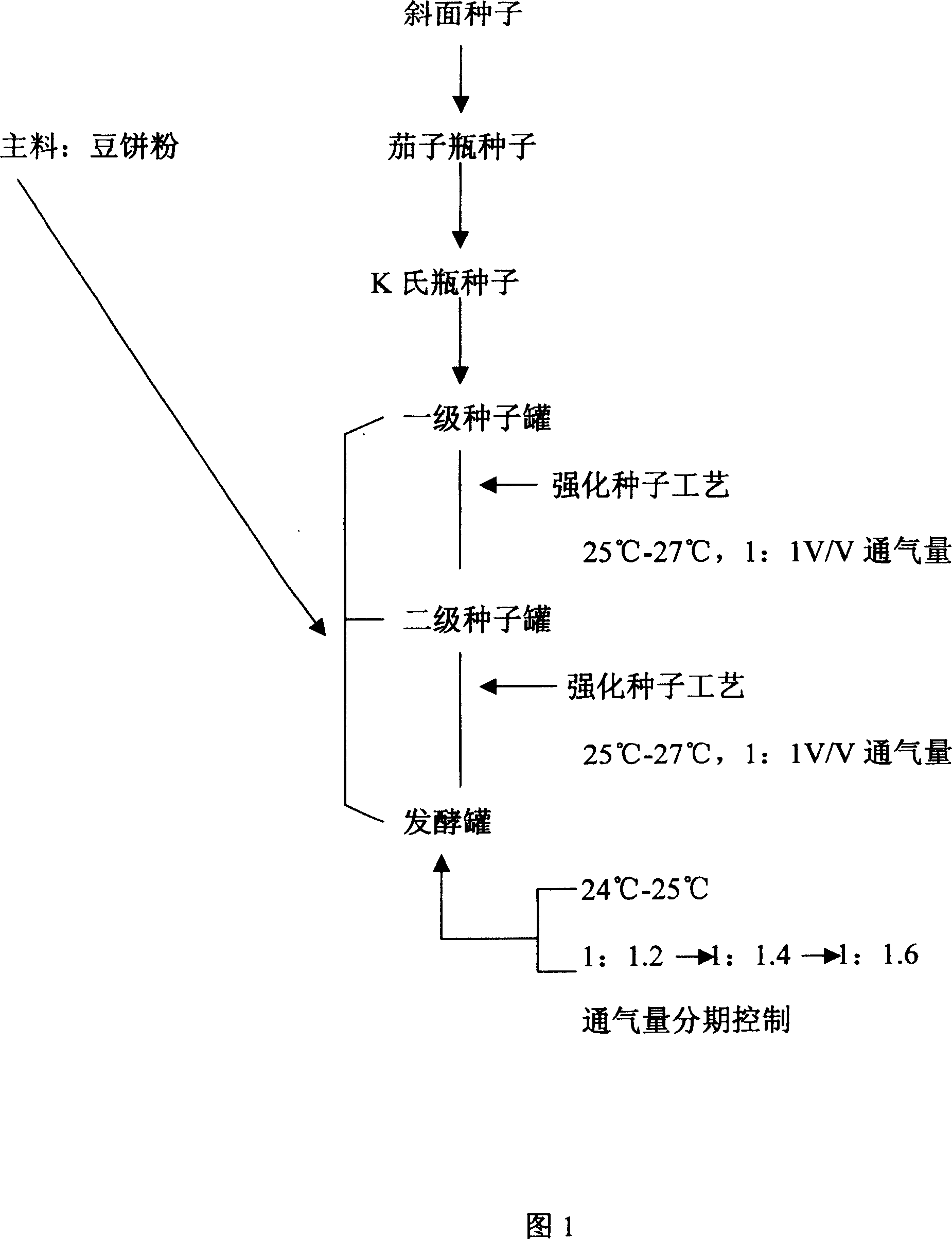

[0023] Seed preparation of strains: the strain S-7749 was grown at 27°C by expanding the potato slant seeds into eggplant bottles for cultivation, and then expanding into K-flasks for cultivation, and the cultivation time for each step was 100 hours.

[0024] Fermentation:

[0025] 1) Primary seed tank fermentation

[0026] Medium (%):

[0027] Soya bean cake flour 2.6

[0028] Cornstarch 0.5

[0029] NaNo 3 0.5

[0030] Sodium citrate 0.08

[0031] MGSO 4 0.04

[0032] Inoculation method: spore inoculation

[0033] Training conditions:

[0034] Temperature: 26°C

[0035] Ventilation volume: 1:1V / V

[0036] pH: 6.3-6.4

[0037] Culture period: 17 hours

[0038] 2) Secondary seed tank fermentation

[0039] Medium (%): fermented in the same level of seed tank

[0040] Inoculation method: pressure difference transplantation method

[0041] Culture conditions

[0042] Temperature: 26°C

[0043] Venti...

example 2

[0067] Similar to Example 1, the difference is that the temperature in the seed preparation process of the bacteria is 26°C, and the cultivation time in the eggplant bottle and the K bottle is 120 hours; the fermentation temperature in the primary seed tank is 27°C, and the cultivation period is 18 hours; the fermentation temperature in the secondary seed tank was 27°C, and the culture cycle was 10 hours; the fermentation temperature in the fermenter was 25°C, and the fermentation cycle was 44 hours; After 18 hours of fermentation, it increased to 1:1.4 V / V, and after 35 hours of fermentation, it increased to 1:1.6 V / V.

[0068] The enzyme activity of the liquid after the fermentation in the fermenter was measured was 3216U / ml.

example 3

[0070] Similar to Example 1, the difference is that the temperature in the seed preparation process of the bacteria is 25°C, and the cultivation time in the eggplant bottle and the K bottle is 80 hours; the fermentation temperature in the primary seed tank is 25°C, and the cultivation period is 16 hours; the fermentation temperature in the secondary seed tank was 25°C, and the culture cycle was 8 hours; the fermentation temperature in the fermenter was 25°C, and the fermentation cycle was 42 hours; After 15 hours of fermentation, it increased to 1:1.4 V / V, and after 30 hours of fermentation, it increased to 1:1.6 V / V. .

[0071] The enzyme activity of the liquid after the fermentation in the fermenter was measured was 3016U / ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com