Magnetic graphene based fe n+ Three-dimensional electrode heterogeneous electro-fenton treatment method of printing and dyeing wastewater

A magnetic graphene, printing and dyeing wastewater technology, applied in the direction of water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of unstable degradation, unsatisfactory reuse effect, etc., to avoid Secondary pollution, good application prospects, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

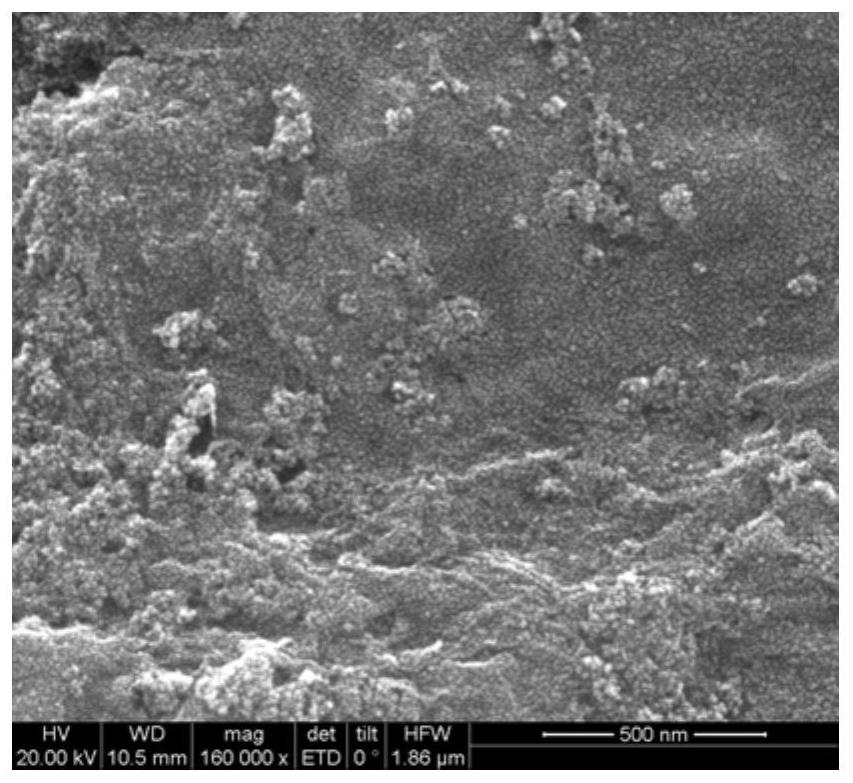

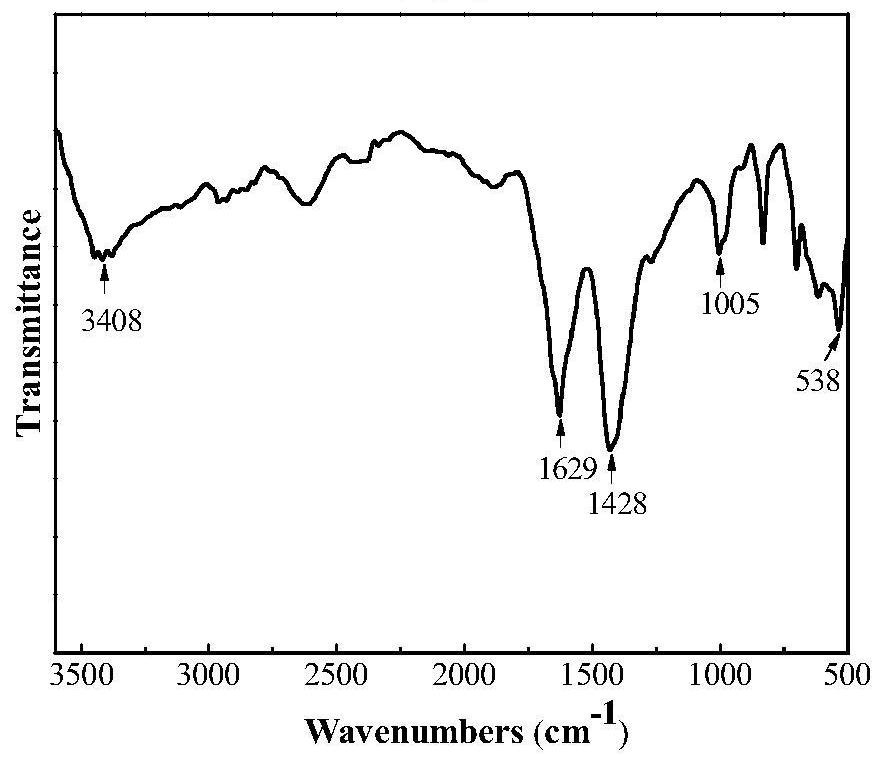

Image

Examples

Embodiment 1

[0044] The present invention adopts magnetic graphene-based Fe n+ An embodiment of the method for processing printing and dyeing wastewater by three-dimensional particle electrode heterogeneous electro-Fenton, the method for processing printing and dyeing wastewater includes the following steps:

[0045] 1) The magnetic graphene-based Fe n+ Particle materials are added to the reaction tank of printing and dyeing wastewater;

[0046] 2) After fully mixing evenly, adjust the pH value of the sewage to 3, 6, 9, and 11 respectively, and carry out mechanical stirring and aeration to make the magnetic graphene-based Fe n+ The particle material is suspended in the reaction tank;

[0047] 3) At an electrolysis current of 0.65A and a current density of 8.89mA / cm 2 Electro-Fenton reaction under the conditions for 240min, then magnetic separation and precipitation, recovery of magnetic graphene-based Fe n+ Particle material; measure effluent COD, methylene blue concentration value, an...

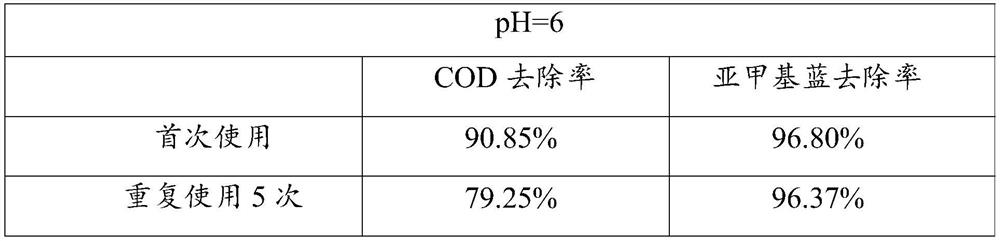

Embodiment 2

[0053] The present invention adopts magnetic graphene-based Fe n+ An embodiment of the method for processing printing and dyeing wastewater by three-dimensional particle electrode heterogeneous electro-Fenton, the method for processing printing and dyeing wastewater includes the following steps:

[0054] 1) The magnetic graphene-based Fe n+ Particle materials are added to the reaction tank of printing and dyeing wastewater;

[0055] 2) After fully mixing evenly, adjust the pH value of the sewage to 6, and carry out mechanical stirring and aeration to make the magnetic graphene-based Fe n+ The particle material is suspended in the reaction tank;

[0056] 3) At an electrolysis current of 0.65A and a current density of 8.89mA / cm 2 Electro-Fenton reaction under the conditions for 240min, then magnetic separation and precipitation, recovery of magnetic graphene-based Fe n+ Particle material; measure effluent COD, methylene blue concentration value, and calculate its removal rat...

Embodiment 3

[0063] The present invention adopts magnetic graphene-based Fe n+ An embodiment of the method for processing printing and dyeing wastewater by three-dimensional particle electrode heterogeneous electro-Fenton, the method for processing printing and dyeing wastewater includes the following steps:

[0064] 1) The magnetic graphene-based Fe n+ Particle materials are added to the reaction tank of printing and dyeing wastewater;

[0065] 2) After fully mixing evenly, adjust the pH value of the sewage to 6, and carry out mechanical stirring and aeration to make the magnetic graphene-based Fe n+ The particle material is suspended in the reaction tank;

[0066] 3) At an electrolysis current of 0.16A and a current density of 2.2mA / cm 2 Electro-Fenton reaction under the condition of 220min, magnetic separation and precipitation are carried out to recover magnetic graphene-based Fe n+ Particle material; measure effluent COD, methylene blue concentration value, and calculate its remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com