A kind of porous biomass carbon-based phosphate adsorbent and its preparation method and application

A carbon-based phosphate and biomass technology, applied in the field of phosphate adsorption, can solve the problems of high pH value, less biomass-based adsorbents, and high chemical oxygen demand, and achieve large adsorption capacity, wide pH value range, and high adsorption capacity. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a kind of preparation method of porous biomass carbon-based phosphate adsorbent, comprising the following steps:

[0032] The calcium hydroxide-treated biomass black liquor is evaporated to dryness and then calcined to obtain a porous biomass carbon-based phosphate adsorbent.

[0033] In the present invention, the calcium hydroxide treated biomass black liquor is specifically the waste liquor generated after the biomass is treated with calcium hydroxide; the calcium hydroxide treated biomass black liquor includes calcium hydroxide, lignin, Substances such as hemicellulose and soluble salt ions.

[0034] In the present invention, the calcium hydroxide treated biomass dark night is preferably prepared by a method comprising the following steps:

[0035] The biomass powder, calcium hydroxide and water are mixed and then centrifuged, and the upper black suspension is collected to obtain calcium hydroxide-treated biomass black liquor.

[0036] In the...

Embodiment 1

[0048] Rice straw was air-dried, chopped, ground with a grinder, and sieved through a 40-mesh (0.425 mm) stainless steel sieve to obtain straw powder of uniform size, and then 10 g of Ca(OH) 2 and 10 g of rice straw powder were sequentially poured into 100 mL of distilled water, and stirred gently at room temperature (25 °C) for 4 h. After stirring, the mixture was centrifuged at 5000 rpm, the upper black suspension was collected, and placed in an oven and evaporated to dryness at 80°C; the evaporated solid was transferred to a corundum boat and placed in a programmable tube furnace in N 2 Protected and heated to 800°C at a heating rate of 5°C / min, and calcined at 800°C for 2h. After the furnace was cooled to room temperature, the biochar derived from black liquor was finally obtained, which is the porous biomass charcoal-based phosphate adsorbent, denoted as CaBLC.

[0049] Physical properties and chemical composition testing:

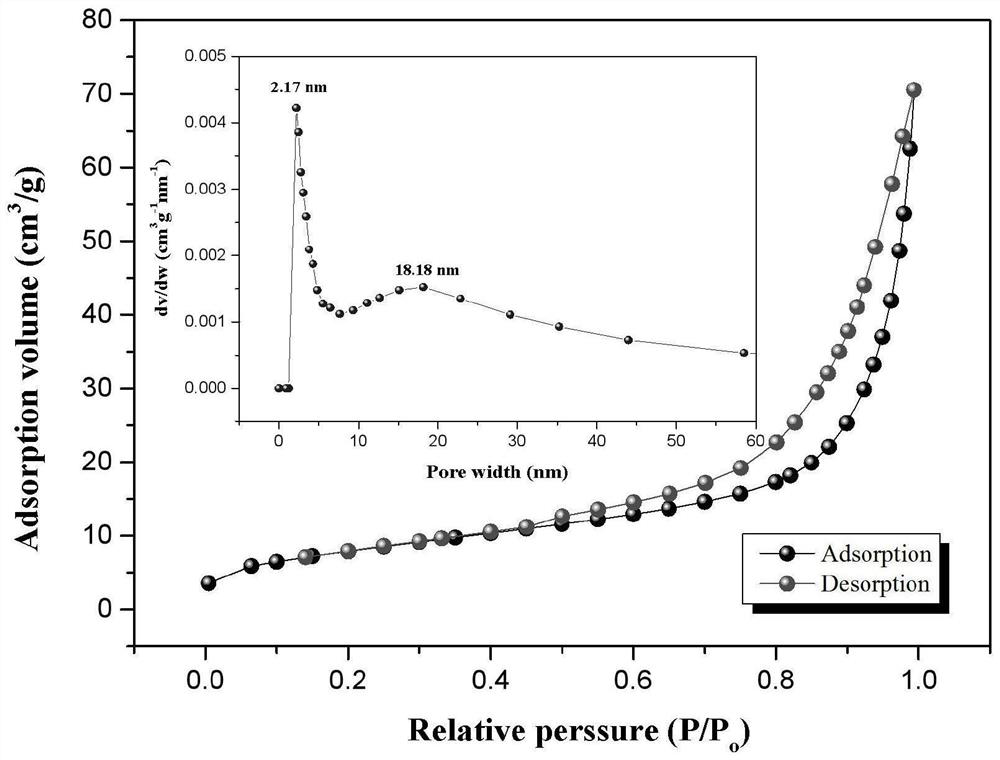

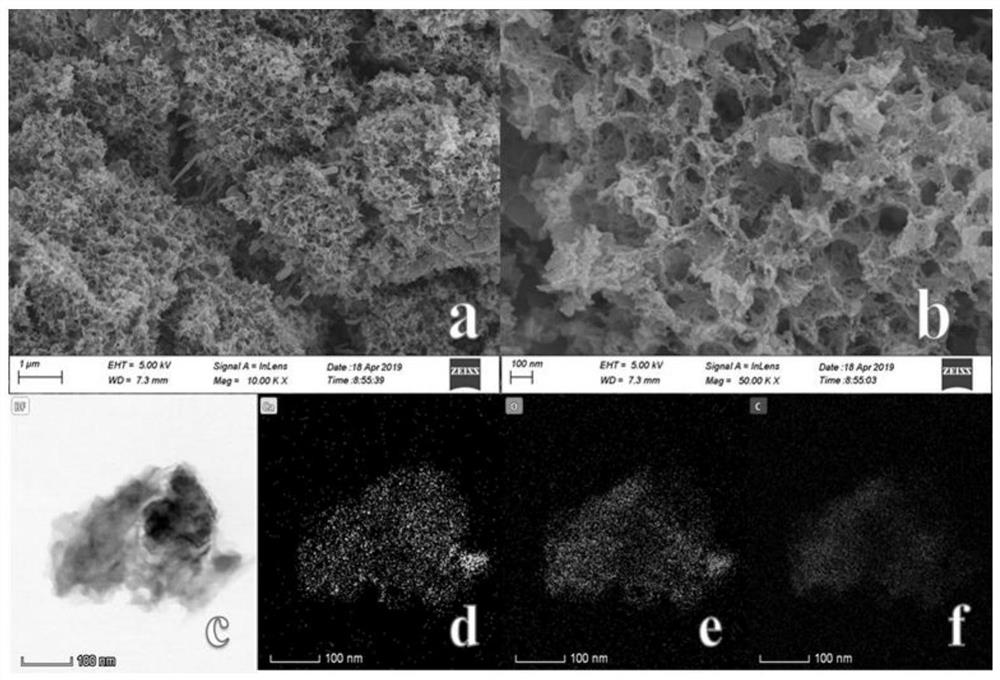

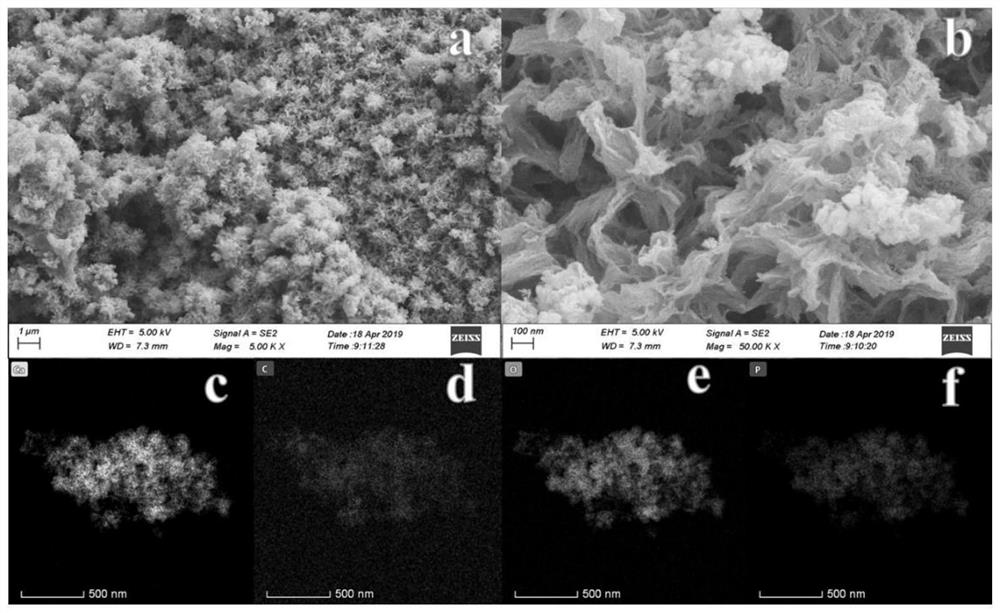

[0050] The specific surface area, pore volum...

Embodiment 2

[0067] The 100 mg / L phosphorus solution was adjusted to different initial pH values (1, 3, 5, 7, 9, 11, 13) using 0.1 M NaOH and HCl solutions. Weigh 10 mg of the CaBLC adsorbent prepared in Example 1 and pour them into 40 ml of the above-mentioned phosphorus solutions with different pHs. After shaking the mixture at 25° C. for 24 h, filter and measure the phosphorus concentration and final pH in the filtrate.

[0068] The result is as Figure 6 shown; according to Figure 6 It can be seen that when the pH of the reaction system is 1 and 3, the phosphorus adsorption capacity of CaBLC is 107.5 mg / g and 136.3 mg / g respectively; when the pH increases to 5-13, the adsorption capacity increases to 184.3-205.7 mg / g g; It can be seen that as the pH of the reaction system increases, the phosphorus adsorption capacity of CaBLC increases, and in a wide pH range, CaBLC has a high adsorption capacity for phosphate, which has great potential in practical applications. potential.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com