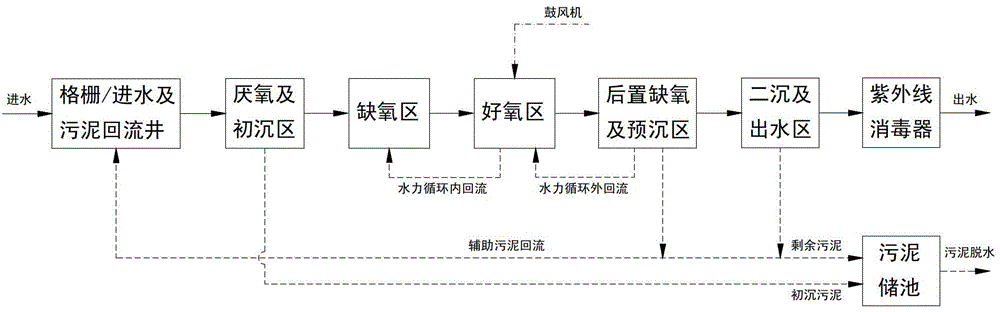

Constant-effluent variable-load SVBR sewage processing technology

A sewage treatment and process technology, applied in the direction of aerobic and anaerobic process treatment, can solve the problems of complex automatic control, high operating cost, poor treatment effect, etc., to simplify the process and structure, avoid secondary upgrading, improve The effect of volume utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

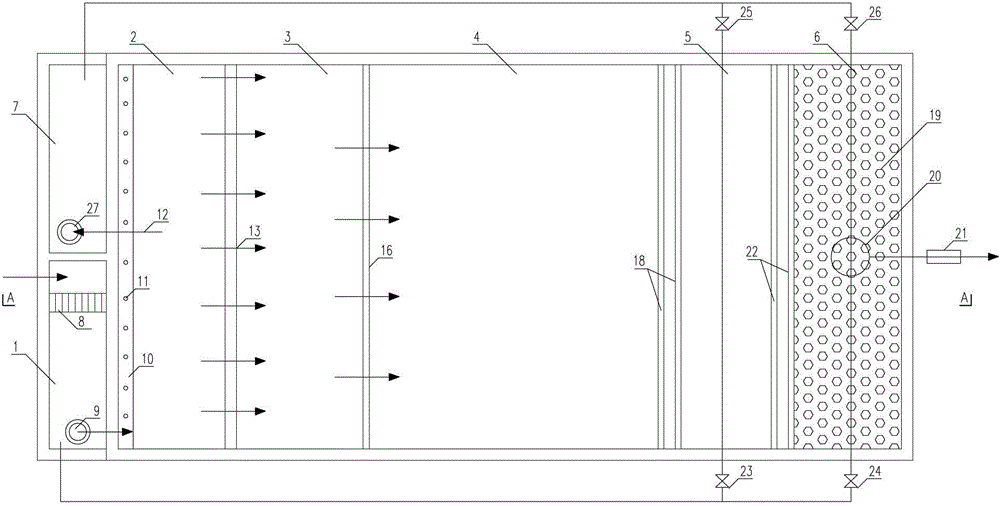

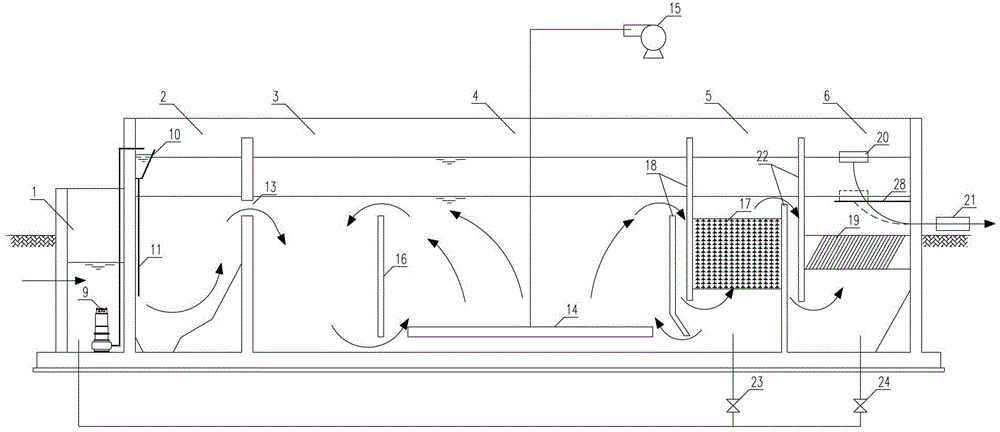

[0086] use as figure 1 A constant rheological load SVBR sewage treatment process and device shown in -3 to treat a small town of 1000m 3 / d domestic sewage.

[0087] Design water quality:

[0088] COD cr 300mg / L; NH 3 -N30mg / L; TP4mg / L; SS180mg / L

[0089] Requirements for effluent water quality: meet the first-class B standard in the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002).

[0090] The relevant design parameters are as follows: the average flow rate of influent water is 41.7m 3 / h; maximum flow rate 85.9m 3 / h; the designed daily continuous drainage time is 20h, the drainage safety factor is 24 / 20=1.2, and one floating decanter is set at 20, the total design drainage capacity is 41.7×1.2=50m 3 / h; the effective volume of water inlet and sludge return well 1 is 25m 3 , the maximum sludge load 0.10kgBOD 5 / kgMLSS.d, the total amount of auxiliary return sludge is 50% of the average influent flow rate; the surface hydraulic load o...

Embodiment 2

[0095] use as Figure 1-3 A constant rheological load SVBR sewage treatment process and device shown to treat a 500m 3 / d domestic sewage.

[0096] Design water quality: COD cr 350mg / L; NH 3 -N40mg / L; TP4mg / L; SS200mg / L

[0097] The effluent water quality is required to meet the first-class B standard in the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002).

[0098] The relevant design parameters are as follows: the average flow rate of influent water is 20.8m 3 / h; maximum flow 46.4m 3 / h; design continuous drainage time of 20h per day, drainage safety factor 24 / 20=1.2, set 1 floating decanter 20, design total drainage capacity 20.8×1.2=25m 3 / h; the effective volume of water inlet and sludge return well 1 is 15m 3 , the maximum sludge load 0.10kgBOD 5 / kgMLSS.d, the total amount of auxiliary return sludge is 50% of the average influent flow rate; the surface hydraulic load of anaerobic and primary sedimentation zone 2 is 3.0m 3 / m 2 ...

Embodiment 3

[0103] use as Figure 1-3 A constant rheological load SVBR sewage treatment process and device shown in a small town of 3000m 3 / d's comprehensive sewage.

[0104] Design scale: 3000m 3 / d.

[0105] Design water quality: COD cr 350mg / L; NH 3 -N40mg / L; TP5mg / L; SS200mg / L.

[0106] The effluent water quality is required to meet the secondary standard in the Discharge Standard of Pollutants for Urban Sewage Treatment Plants (GB18918-2002).

[0107] The relevant design parameters are as follows: the average flow rate of influent water is 125m 3 / h; maximum flow 229m 3 / h; the designed daily continuous drainage time is 22h, the drainage safety factor is 24 / 22=1.1, and the design drainage capacity of the decanter is 125×1.1=137.5m 3 / h; the effective volume of water inlet and sludge return well 1 is 65m 3 , the maximum sludge load 0.12kgBOD 5 / kgMLSS.d, the total amount of auxiliary return sludge is 20% of the average influent flow rate; the surface hydraulic load of anaer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com