Method for purifying slime water by compounding biological and abiological flocculants of coal

A technology of biological flocculant and coal slime water, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as interference, inability to achieve large-scale use, etc., and achieve reduced conditions The effect of limiting, reducing usage, and reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

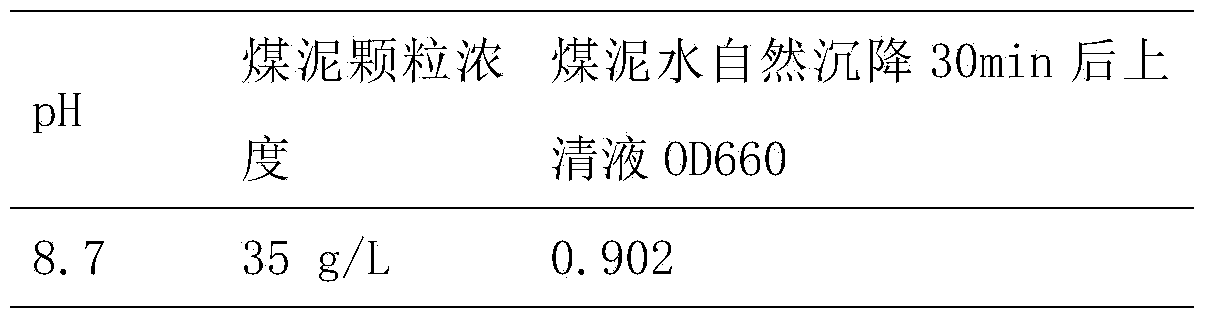

[0028] 1) Take 90mL of well-stirred coal slime water, and then add 2% CaCl 2 Coagulant aid 3mL, stir with a magnetic slow speed stirrer for 1min;

[0029] 2) Add 2mL of coal bioflocculant, add coal slime water to 100mL, adjust the pH value of coal slime water to 5 with a pen-type pH meter, then stir at a slow speed with a magnetic stirrer for 5min, and add 0.05mL of non-biological flocculant polyacrylamide , stir well.

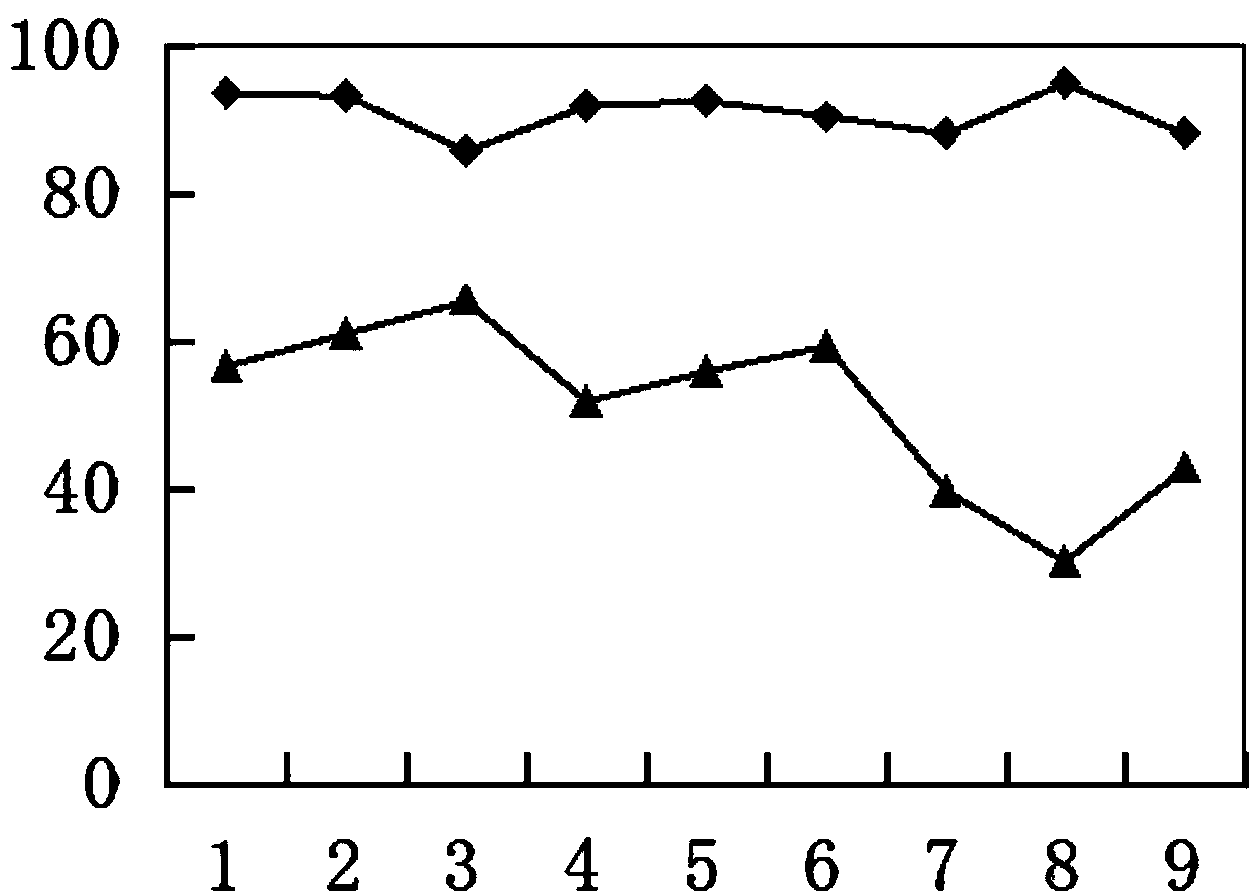

[0030] 3) Stand still for 30 minutes to absorb the supernatant, measure the absorbance value of the supernatant at 660nm with a UV-5100 ultraviolet spectrophotometer, and obtain a flocculation rate of 93.57%. When other conditions remained unchanged, only 2 mL of Phanerochaete chrysosporium was added, and the flocculation rate was 56.65%.

example 2

[0032] 1) Take 90mL of well-stirred coal slime water, and then add 2% CaCl 2 Coagulant aid 2mL, stir with a magnetic slow speed stirrer for 1min;

[0033] 2) Add 1mL of coal bioflocculant, add more coal slime water to 100mL, adjust the pH value of the coal slime water to 7 with a pen-type pH meter, then stir at a slow speed with a magnetic stirrer for 5min, add non-biological flocculant polyacrylamide 0.05mL , stir well.

[0034] 3) Stand still for 30 minutes to absorb the supernatant, measure the absorbance value of the supernatant at 660nm with a UV-5100 ultraviolet spectrophotometer, and obtain a flocculation rate of 93.23%. When other conditions remained unchanged, only 1 mL of Phanerochaete chrysosporium was added, and the flocculation rate was 61.09%.

example 3

[0036] 1) Take 90mL of well-stirred coal slime water, and then add 2% CaCl 2 Coagulant aid 1mL, stir with a magnetic slow speed stirrer for 1min;

[0037] 2) Add 3mL of coal bioflocculant, add coal slime water to 100mL, adjust the pH value of the coal slime water to 6 with a pen-type pH meter, then stir slowly for 5min with a magnetic stirrer, and add 0.05mL of non-biological flocculant polyacrylamide , stir well.

[0038] 3) Stand still for 30 minutes to absorb the supernatant, measure the absorbance value of the supernatant at 660nm with a UV-5100 ultraviolet spectrophotometer, and obtain a flocculation rate of 85.81%. When other conditions remained unchanged, only 3mL of Phanerochaete chrysosporium was added, and the flocculation rate was 65.63%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com