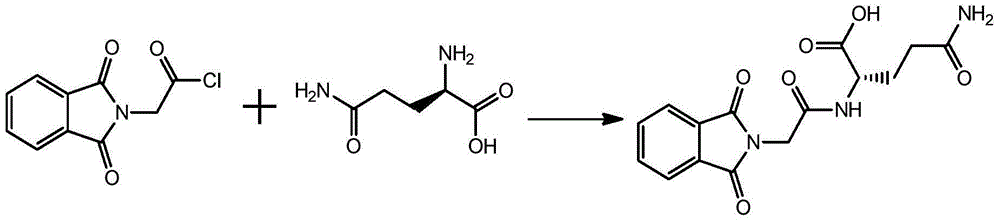

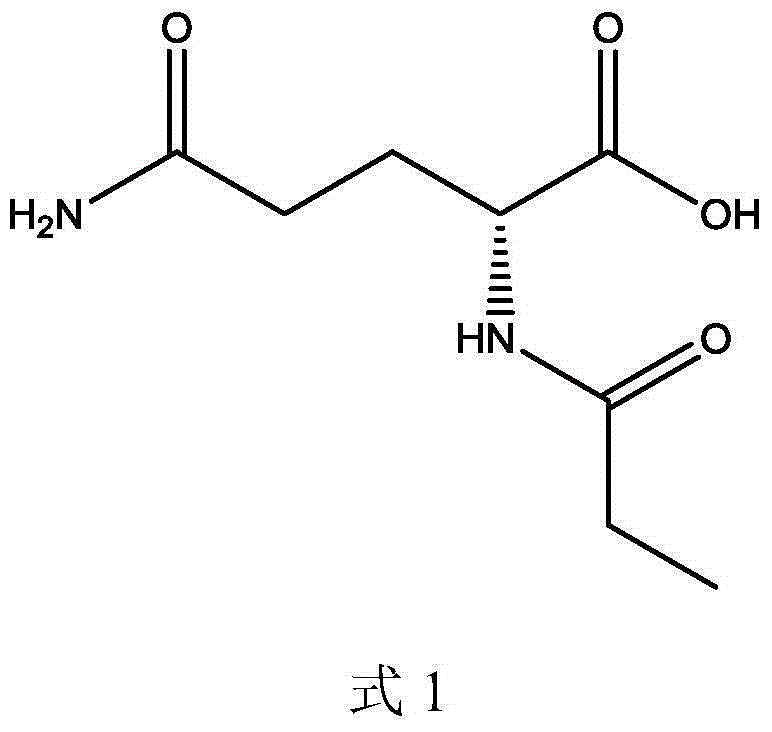

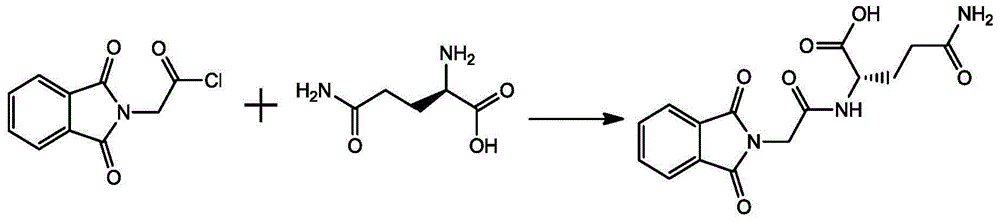

Green preparation method of phthaloylglycyl-l-glutamine

A technology of phthaloyl glycyl and glutamine, which is applied in the field of medicine, can solve the problems of high energy consumption, high requirements for equipment and personnel, harm to the environment and operators, etc., and achieves low cost, green cost and environmental protection. , the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 16g of caustic soda and 40g of soda ash to 500mL of water, and add 50g of L-glutamine, stir to dissolve, and cool the resulting reaction solution to -7°C to form a solution. Phthaloylglycyl chloride was rapidly added dropwise at a rate of 2.5 g / s, during which the temperature of the reaction solution was controlled between 9 and 10°C. After the dropwise addition, the reaction was stirred for 60 minutes. Then slowly add 12 mol / L hydrochloric acid solution to the solution, adjust the pH to 4, stir for 9 minutes, and a large amount of white solids are precipitated. Continue to dropwise add 0.2 mol / L hydrochloric acid solution to the reaction solution, adjust the pH to 1.5, and completely precipitate the product, and stir for 5 minutes. The solid was filtered and dried to obtain 111.9 g of the product phthalylglycyl-L-glutamine, with a yield of 98.2%. According to high performance liquid chromatography (HPLC), its phthalylglycyl-L- The purity of L-glutamine is 99.1%. ...

Embodiment 2

[0035] Add 16g of caustic soda and 40g of soda ash to 500mL of water, and add 50g of L-glutamine, stir to dissolve, and cool the resulting reaction solution to -8°C to form a solution. Rapidly phthaloylglycyl chloride at a rate of 2.8g / s, during which the temperature of the reaction solution is controlled between 9 and 10°C. After the dropwise addition, the reaction was stirred for 60 minutes. Then slowly add 12 mol / L hydrochloric acid solution to the solution, adjust the pH to 3, stir for 9 minutes, and a large amount of white solids are precipitated. Continue to dropwise add 0.2 mol / L hydrochloric acid solution to the reaction solution, adjust the pH to 1.5, and completely precipitate the product, and stir for 5 minutes. The solid was filtered and dried to obtain 112.3 g of the product phthaloylglycyl-L-glutamine, with a yield of 98.5% and an HPLC purity of 99.2%.

Embodiment 3

[0037] Add 18g of caustic soda and 40g of soda ash to 500mL of water, add 50g of L-glutamine, stir to dissolve, and cool the resulting reaction solution to -7°C. Rapidly phthaloylglycyl chloride at a rate of 2.8g / s, during which the temperature of the reaction solution is controlled between 9 and 10°C. After the dropwise addition, the reaction was stirred for 60 minutes. Then, 6N sulfuric acid solution was slowly added to the solution to adjust the pH to 3, and stirred for 9 minutes, and a large amount of white solid was precipitated. Continue to add 0.2 mol / L hydrochloric acid solution dropwise to the reaction solution, adjust the pH to 2, and completely precipitate the product, and stir for 5 minutes. The solid was filtered and dried to obtain 111.9 g of the product phthaloylglycyl-L-glutamine, with a yield of 98.2% and an HPLC purity of 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com