Conjugated polymer containing thienothiophene and di(benzothieno)benzodithiophene, and preparation method and application thereof

A technology of dibenzothiophene and benzodithiophene is applied in the field of conjugated polymer containing thienothiophene-dibenzothiophenebenzodithiophene and its preparation, and can solve the problems of narrow light absorption range and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

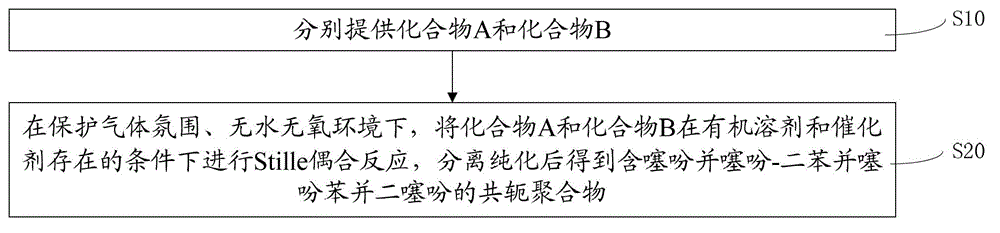

[0061] Such as figure 1 As shown, the preparation method of the above-mentioned conjugated polymer containing thienothiophene-dibenzothiophene benzodithiophene comprises the following steps:

[0062] S10, compound A and compound B respectively provided.

[0063] Compound A and Compound B have the following structural formulas respectively:

[0064]

[0065] R 1 and R 2 The same as H, C 1 ~C 10 Alkyl or C 1 ~C 10 The alkoxyl group, R 3 for C 1 ~C 16 Alkyl or C 1 ~C 16 of alkoxy.

[0066] The preparation method of compound A comprises the steps:

[0067] S111, providing compound C and compound E having the following structural formula:

[0068]

[0069] R 1 and R 2 The same as H, C 1 ~C 10 Alkyl or C 1 ~C 10 of alkoxy.

[0070] S112. Under the condition of protective gas atmosphere and -78°C, add n-butyllithium into the organic solution of compound C, stir for 2h~3h, then add trimethyltin chloride to the above system, and react for 0.5h~1h Then return...

Embodiment 1

[0142] This example discloses a conjugated polymer P1 containing thienothiophene-dibenzothiophenebenzodithiophene with the following structural formula:

[0143]

[0144] Wherein, R is 2-hexyloctyl; n=60.

[0145] The preparation process of conjugated polymer P1 is as follows:

[0146] 1. The monomer compound 4,11-dibromo-7,8-diodecyldibenzo[b,b']thiophenebenzo[2,1-b:3,4-b']di Synthesis of thiophene (A):

[0147]

[0148] 1. Synthesis of compound 4,5-dicecyl-2,7-trimethyltinbenzo[2,1-b:3,4-b’]dithiophene (D)

[0149]

[0150] Under nitrogen protection, add 2.36g (5mmol) 4,5-dicecylbenzo[2,1-b:3,4-b']dithiophene (C) into 60mL anhydrous ether solution, cool To -78°C, slowly add 5mL (12mmol) of n-butyllithium in n-hexane solution (2.5M). Tin, return to room temperature after 0.5h of heat preservation reaction, continue to react for 24h, and obtain the product, that is, 4,5-dicecyl-2,7-trimethyltinbenzo[2,1-b:3,4-b' ] Dithiophene (D).

[0151] MS(EI)m / z:796(M + ). ...

Embodiment 2

[0188] This example discloses a conjugated polymer P2 containing thienothiophene-dibenzothiophenebenzodithiophene with the following structural formula:

[0189]

[0190] Wherein, n=50; R is 2-ethylhexyl.

[0191] The preparation process of conjugated polymer P2 is as follows:

[0192] 1. The monomer compound 4,11-dibromo-7,8-bis(2-ethylpentyl)dibenzo[b,b']thiophenebenzo[2,1-b:3, Synthesis of 4-b']dithiophene (A):

[0193]

[0194]1. Compound 4,5-bis(2-ethylpentyl)-2,7-bis(trimethyltin)benzo[2,1-b:3,4-b']dithiophene (D) synthesis

[0195]

[0196] Under nitrogen protection, add 1.93g (5mmol) 4,5-di(2-ethylpentyl)benzo[2,1-b:3,4-b']dithiophene (C) into 60mL anhydrous In tetrahydrofuran solution, cool to -78°C, slowly add 5mL of n-butyllithium (12.5mmol) in n-hexane solution (2.5M), after the addition is complete, stir and react at -78°C for 2.5h, then add 3.8mL of Tris Methyl tin chloride (12.5mmol), heat preservation reaction for 0.6h and return to room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com