Inner wall thermal insulation base layer paste, preparation and applications thereof

A technology for base layer and interior wall, applied in the direction of filling slurry, etc., can solve the problems of unacceptable and widely used interior wall thermal insulation putty, poor thermal insulation effect of thermal insulation putty, poor water resistance of the putty layer, etc., and achieves remarkable and good thermal insulation effect. Thermal insulation effect, good water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

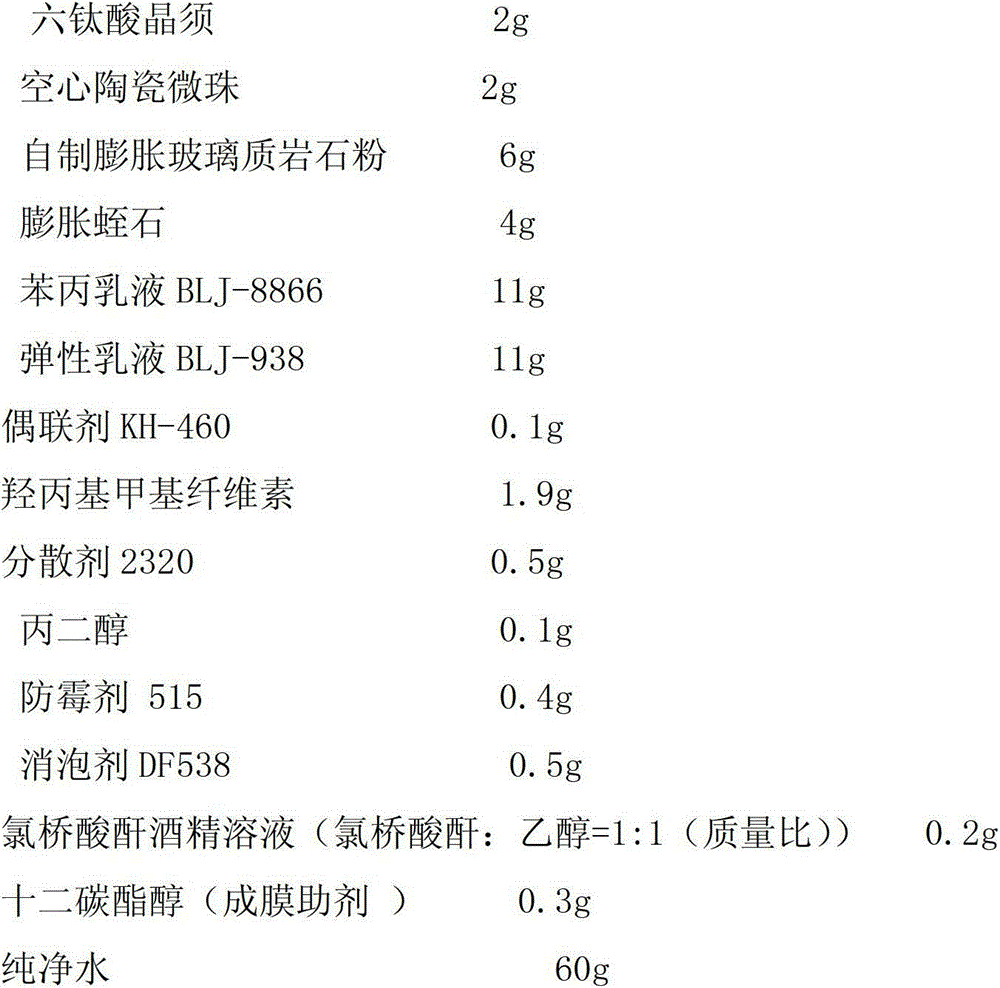

[0027] Preparation of embodiment 1 interior wall thermal insulation base paste

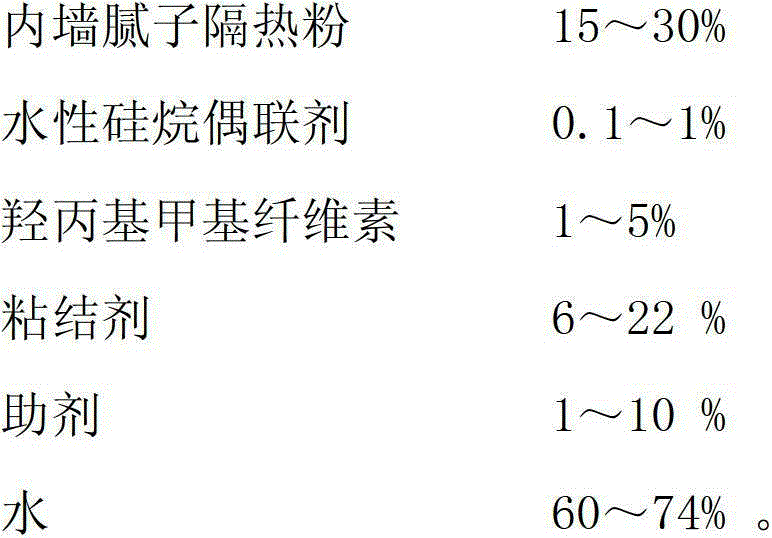

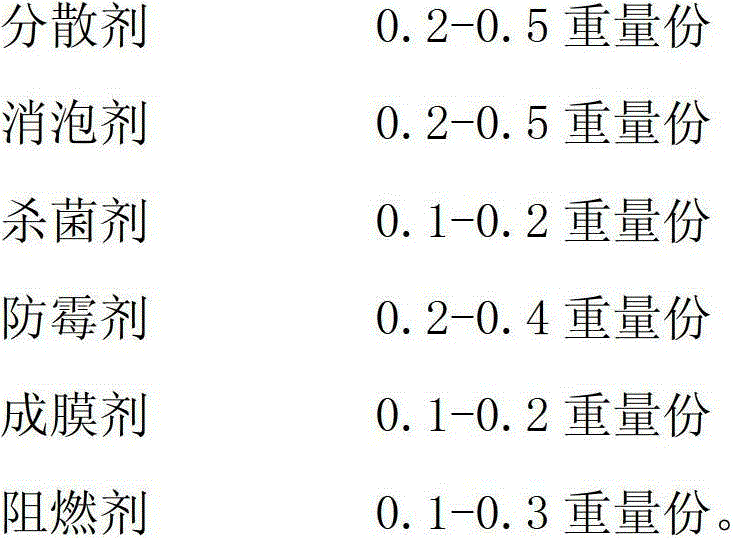

[0028] 1. Raw material

[0029] Dispersible rubber powder SF8240 and dispersible rubber powder DM200 were purchased from Shanghai Shunshui Chemical Co., Ltd.; dispersible rubber powder SF8240 and dispersible rubber powder DM200 were purchased from Shanghai Shunshui Chemical Co., Ltd.; elastic emulsion BLJ-938, Styrene-acrylic emulsion BLJ-8866 was purchased from Shanghai Polyjia Chemical Co., Ltd.; polyvinyl alcohol 2488 was purchased from Shanghai Lite Chemical Technology Co., Ltd.; polyvinyl alcohol 1799 was purchased from Huazhi Chemical Technology Co., Ltd.; dispersant S-70S, defoaming agent Agent DF538 was purchased from Shanghai Zhongcheng Chemical Co., Ltd.; Dispersant 2320 was purchased from Shenzhen Haichuan Co., Ltd. Waterborne silane coupling agent KH-460 was purchased from Suzhou Patna Chemical Co., Ltd.

[0030] 2. Coating Preparation

[0031] 1) Method 1:

[0032] The composition...

Embodiment 2

[0052] Example 2 Detection of Inner Wall Thermal Insulation Base Paste

[0053] 1. Performance test of interior wall insulation base paste

[0054] 1) Experimental object: the interior wall thermal insulation base paste obtained from methods 1 to 5 of Example 1

[0055]2) Experimental results: Table 1 shows the performance test data of the inner wall thermal insulation base paste of the present invention.

[0056] Table 1 Example 1 The detection data of interior wall thermal insulation base paste

[0057]

[0058] 2. Thermal conductivity test of interior wall insulation base paste

[0059] 1) Experimental object:

experiment example

[0060] Experimental example: the inner wall thermal insulation base paste prepared by method 1-5 of embodiment 1 of the present invention; comparative example: common

[0061] Putty paste.

[0062] 2) Experimental method:

[0063] Experimental content: test the actual thermal conductivity of the coating after construction and maintenance

[0064] Experimental basis: GB / T10297-2008 "The heat flow meter method for the determination of the steady-state thermal resistance and related characteristics of thermal insulation materials"

[0065] 3) Experimental results

[0066] Table 2 Test data of interior wall insulation base paste

[0067] Ordinary interior wall putty paste

method 1

Method 2

Method 3

Method 4

Method 5

about 0.3W / m·k

0.046W / m·k

0.045W / m·k

0.039W / m·k

0.040W / m·k

0.035W / m·k

[0068] 3. The actual thermal insulation effect test of the inner wall thermal insulation base paste

[0069] 1) Experimental obj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com