Automatic dryer for blood collection tubes

A technology for dryers and blood collection tubes, which is applied in the direction of dryers, drying, progressive dryers, etc., can solve the problems of destroying agents and blood collection tubes, burning out heating tubes, and being unable to adjust the speed, so as to improve the accuracy of diagnosis The effect of reducing power consumption, reducing the risk of misdiagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

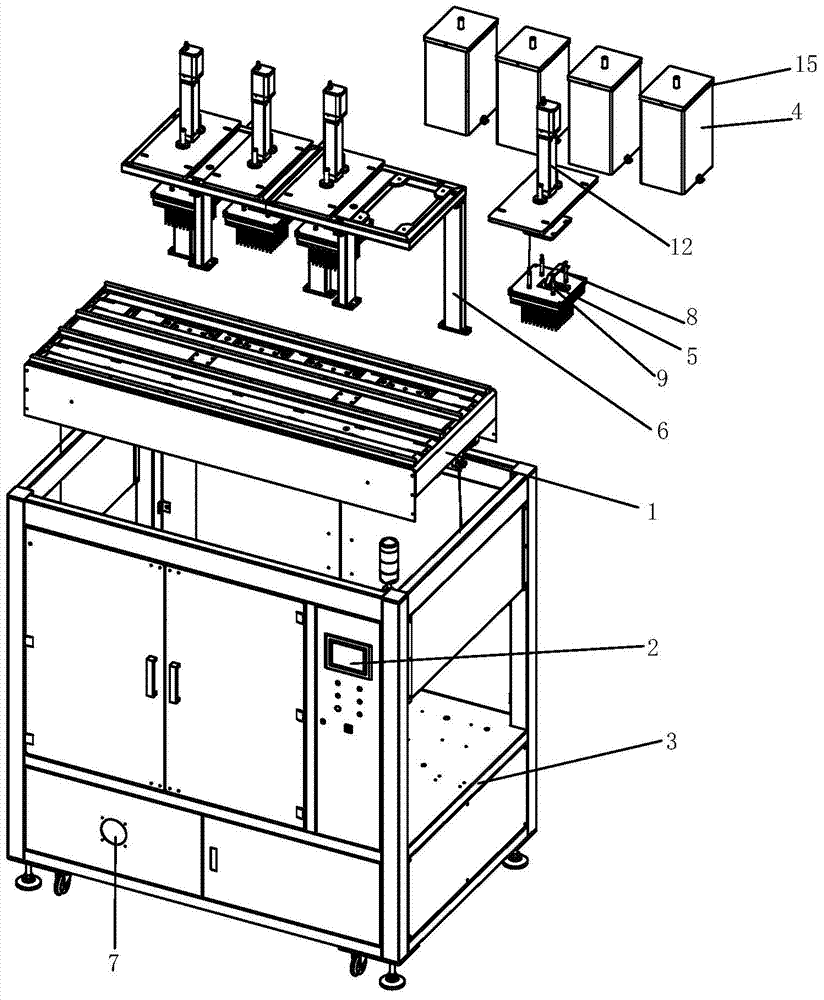

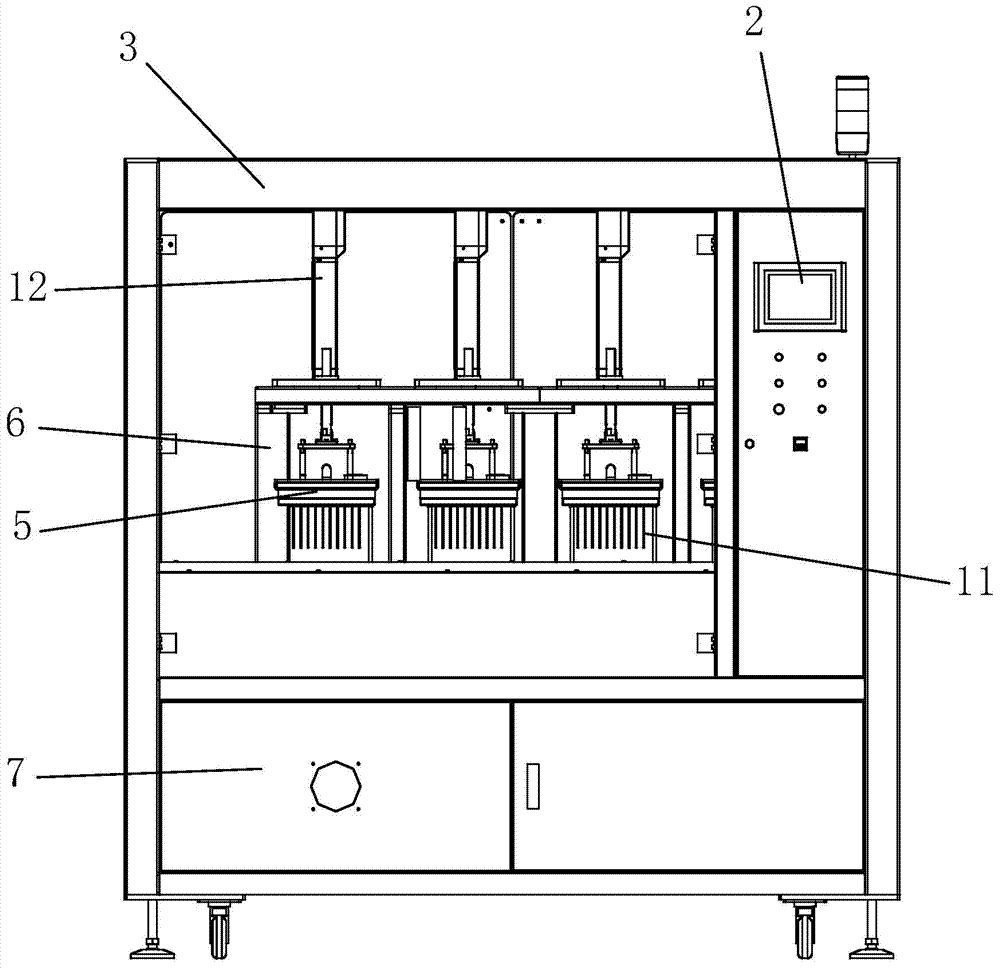

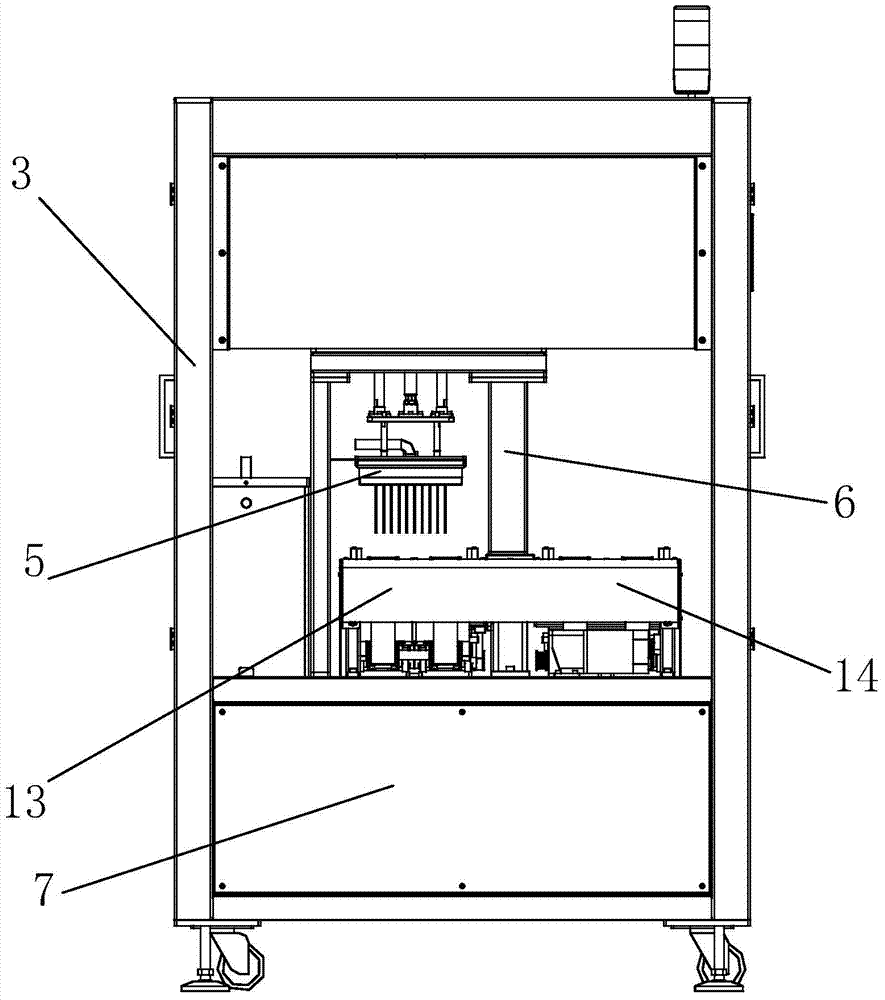

[0030] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , the automatic drying machine for blood collection tubes of the present invention includes a drying module, a transmission group 1, an air control device (such as Figure 5 ), an electrical control device, an operation panel 2 and a frame 3, and the drying module includes a heating box 4, a drying head 5, a drive unit and a drying support 6.

[0031] The drying module, the transmission group 1 , the air control device, the electrical control device and the operation panel 2 are arranged on the frame 3 . The frame 3 is the foundation and frame part of the whole equipment. The material of the frame of the frame 3 is stainless steel or aluminum profile, which can be selected according to customer requirements. The stainless steel table of the frame 3 is stainless steel. Frame 3 adopts aluminum profile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com