Rapid vacuum desorption device and rapid vacuum desorption method for collecting volatile gas components in sample

A volatile gas and sample technology, applied in the field of desorption systems, can solve the problems of inability to quickly separate volatile components, incomplete separation of adsorbates, and difficulty in quantitative measurement, so as to eliminate sample cross-interference, prevent re-adsorption, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

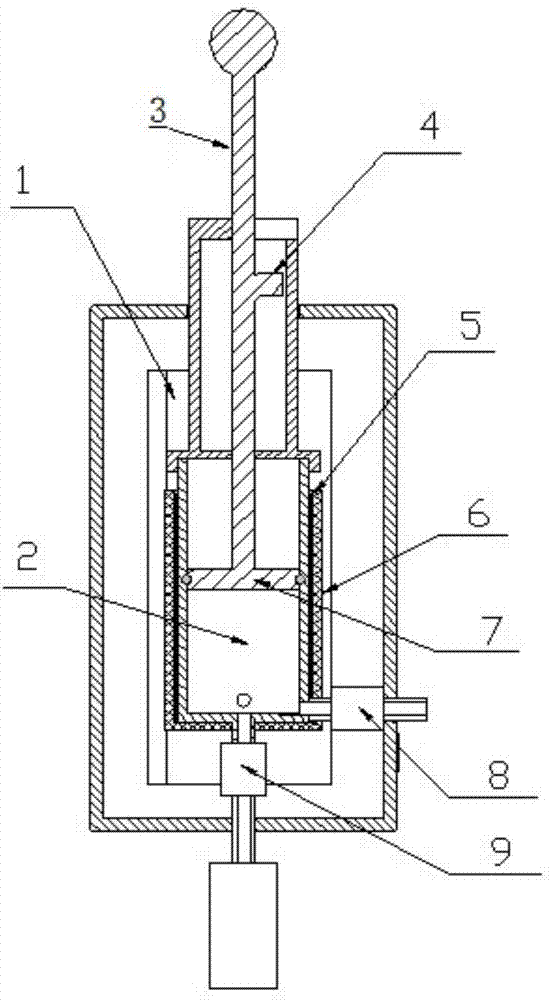

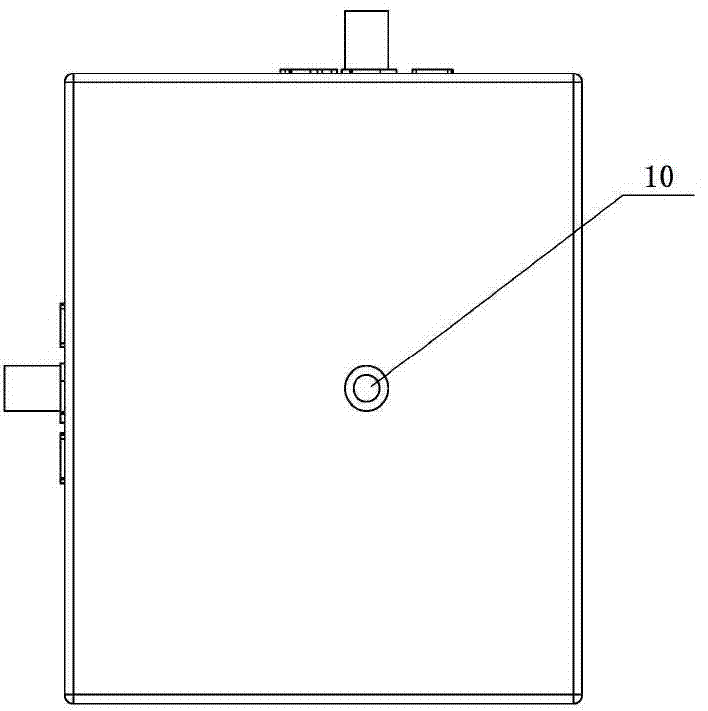

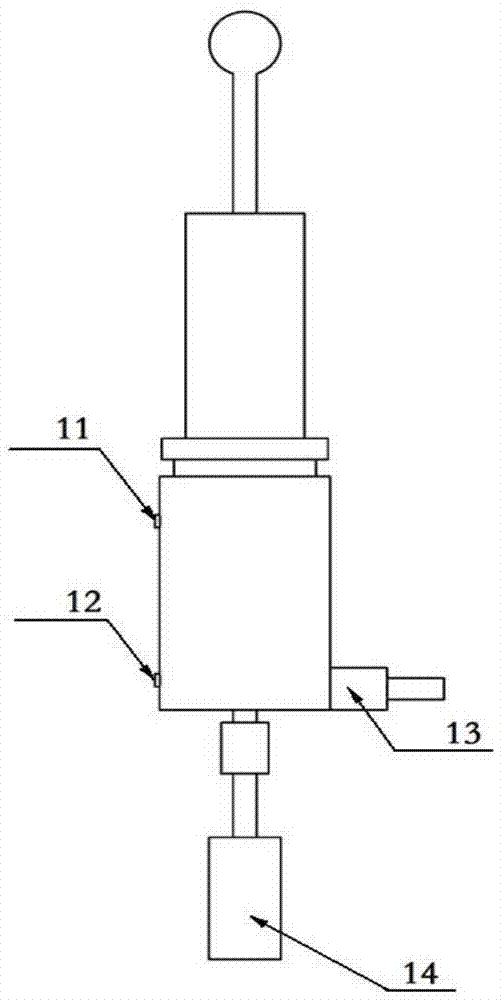

[0041] Such as Figure 1-6 As shown, a fast vacuum desorption device for the collection of volatile gas components in samples, including a suction cylinder 2 (piston cylinder), a suction piston 7 inside the suction cylinder 2 and an extension of it (suction piston) The piston handle 3 and the stop hook 4 between the two, the outer periphery of the suction cylinder 2 is wrapped by the heating layer 5 and the insulation layer 6, and there is an air inlet 10 connected to the air inlet solenoid valve 9 at the bottom of the air suction cylinder 2. The sample bottle 14 is screwed under the solenoid valve 9, and the gas washing port 16 and the gas outlet 17 connected to the gas washing solenoid valve 8 and the gas outlet solenoid valve 13 are respectively arranged on the bottom side of the air suction cylinder 2, and the gas washing solenoid valve 8 and the gas outlet solenoid valve 13 are respectively Connect the air washing port 16 and the air outlet 17 outside the casing; the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com