Multi-target microarray chip full-automatic hybrid cleaning dyeing system

A technology of microarray chip and staining system, which is applied in laboratory utensils, laboratory containers, chemical instruments and methods, etc., can solve the problems of experimental error, inconvenient automatic operation, time-consuming and labor-intensive, etc., and improve repeatability and consistency, improve efficiency and uniformity, and reduce the risk of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

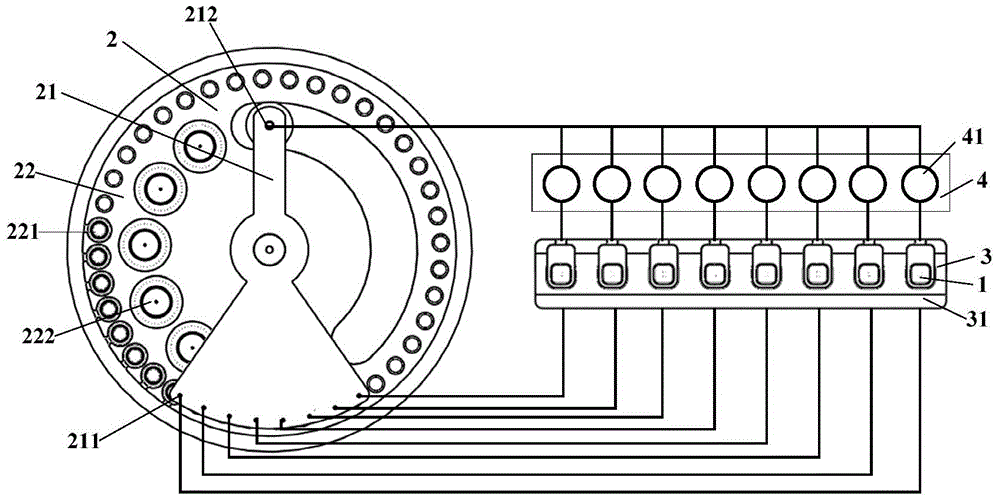

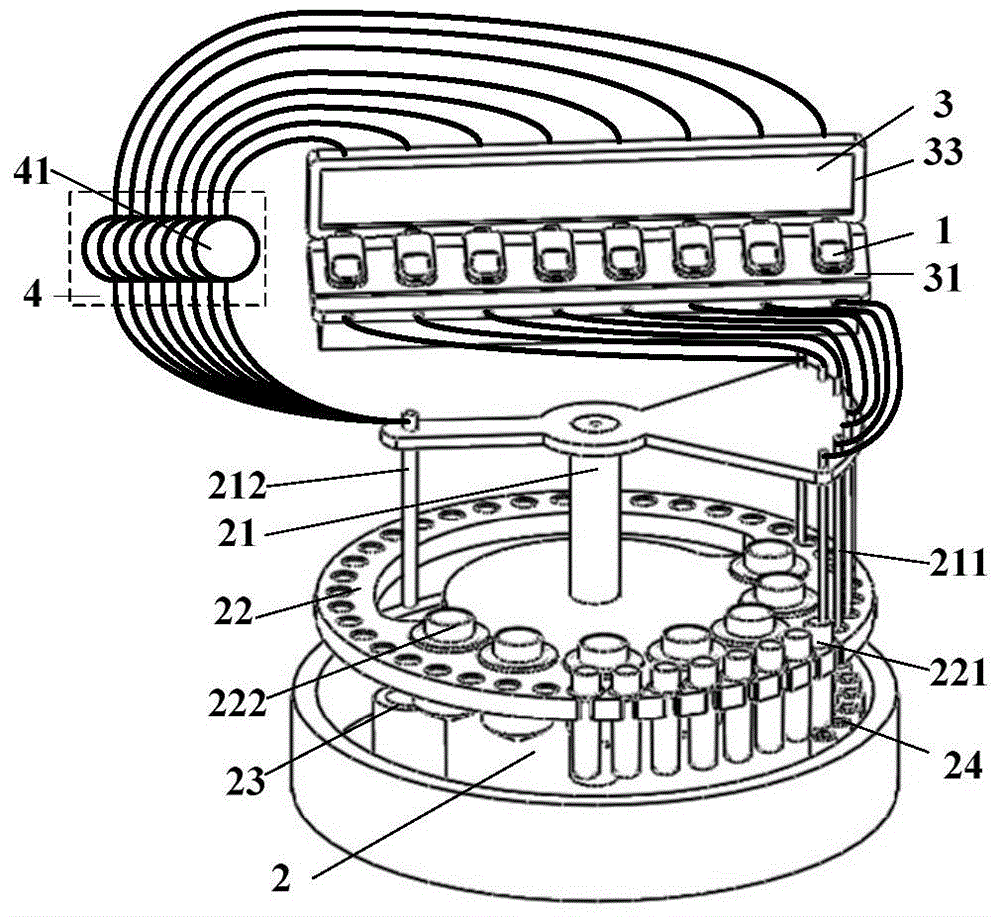

[0023] Such as figure 1 and figure 2 As shown, the system of the present invention is composed of a multi-target microarray chip cartridge 1 , a sample and reagent processing module 2 , an incubation reaction module 3 and a fluid control module 4 .

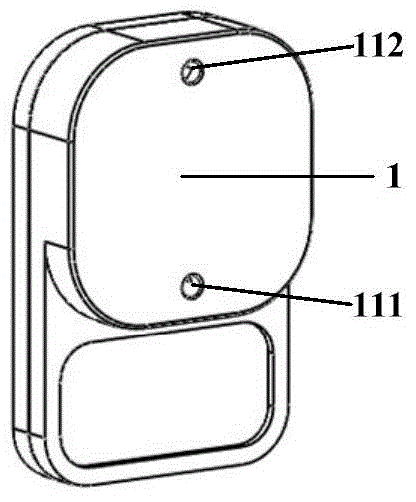

[0024] Such as image 3 and Figure 4 As shown, the multi-target microarray chip cartridge 1 of the present invention is composed of a flow path hole cartridge 11, a fence cartridge 12 and a multi-target microarray chip 13. The flow path hole cartridge 11 has flow path holes 111 and 112, The flow path hole cartridge 11 and the enclosure cartridge 12 can fix and package the multi-target microarray chip 13 in the cavity formed therein, and samples and reaction liquids can enter and exit through the flow path holes 111 and 112 . The fence cartridge 12 has good optical transparency, and the result can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com