Preparation method of extrusion resistant, fire preventing and super hydrophobic sponge

A technology of superhydrophobic sponge and extrusion resistance, which is applied in the field of synthesizing new oil-absorbing superhydrophobic sponge, which can solve the problems of large-scale difficulty of new oil-absorbing materials, and achieve easy large-scale production, simple synthesis method, low price and easy availability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

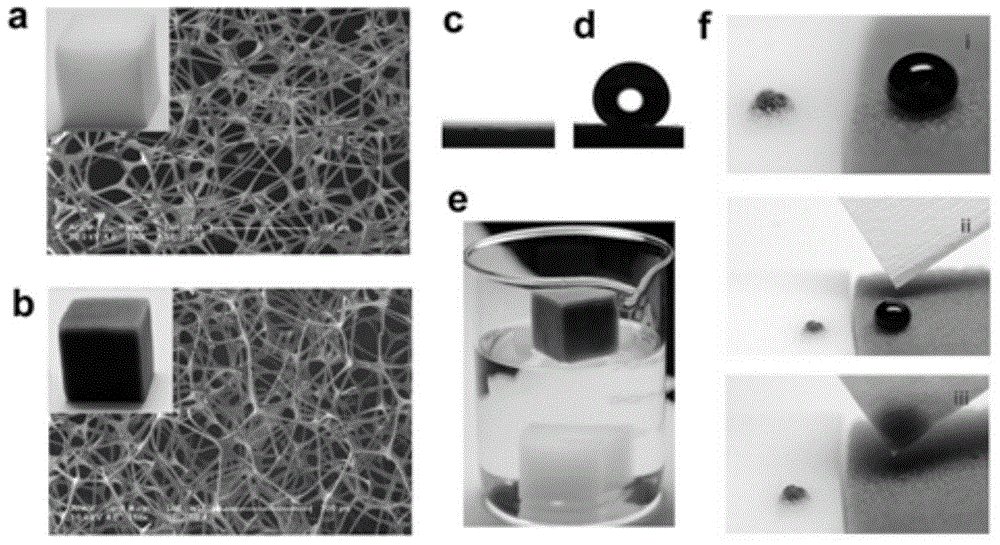

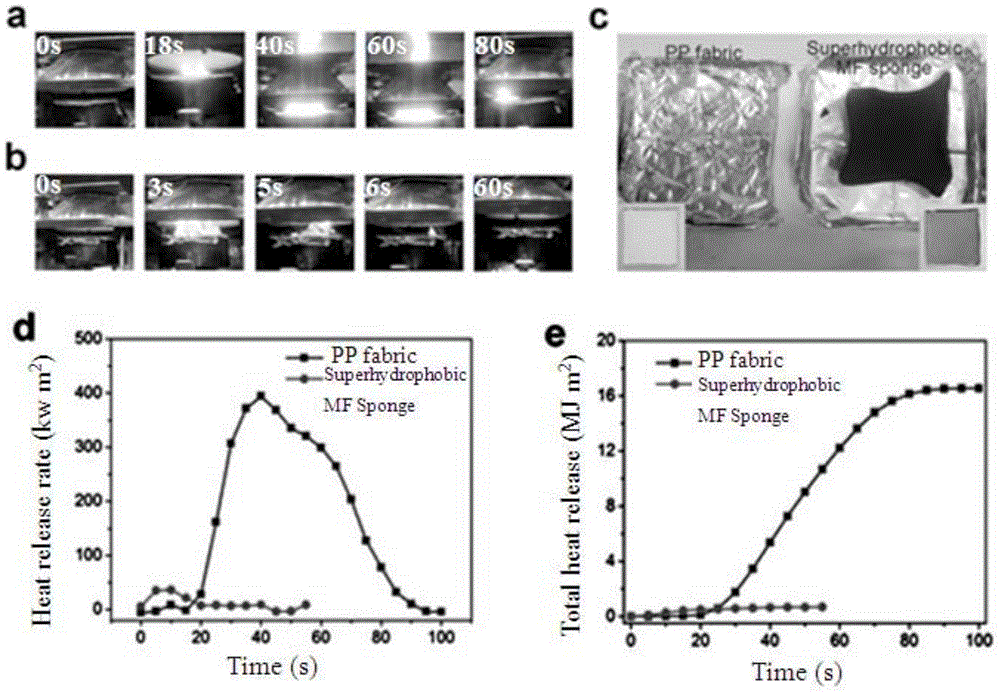

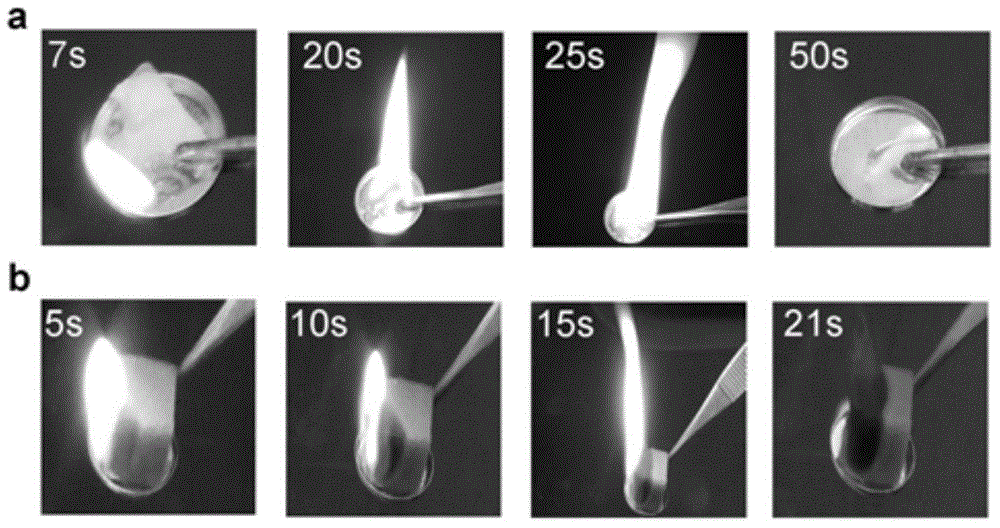

[0029] A preparation method of extrusion-resistant, fireproof and superhydrophobic sponge, specifically comprising the following steps:

[0030] Step (1), soak the melamine resin sponge in an alkaline buffer solution with a pH value of 7-14, add dopamine hydrochloride, dopamine polymerizes on the surface of the melamine resin sponge, react for 10-60 hours, and then use deionized washing with water to obtain polydopamine-coated melamine resin sponge; the concentration of dopamine hydrochloride is 0.06 g / L-3.2 g / L.

[0031]Step (2), soak the polydopamine-coated melamine resin sponge prepared in step (1) in an alkaline ethanol solution with a pH value of 7-14, add mercapto fluorinated long-chain alkanes or mercapto long-chain alkanes, and react 1-24 hours, then washed with ethanol and allowed to dry. Wherein, the melamine resin sponge has open pores with a porosity of 99.8%-60%. The polydopamine is produced by polymerization of dopamine hydrochloride under alkaline conditions. ...

Embodiment 1

[0033] (1) Preparation of polydopamine-coated melamine resin sponge

[0034] Soak the pre-cut melamine resin sponge in 500ml of alkaline buffer solution with a pH value of 8, then add 1.6g of dopamine hydrochloride, and stir or shake evenly for 10 hours. When the reaction time is up, take it out, then wash it three times with deionized water, and let it dry.

[0035] (2) Modification of polydopamine-coated melamine resin sponge

[0036] Soak the polydopamine-coated melamine resin sponge in an alkaline ethanol solution with a pH value of 8.5 containing 2 g / L of mercaptofluoroalkanes (6 carbons), and stir or shake evenly for 24 hours. After reaching the reaction time, take it out, wash it twice with ethanol, and then dry it to obtain the extrusion-resistant, fireproof and superhydrophobic sponge. The prepared material is referred to as material 1.

Embodiment 2

[0038] (1) Preparation of polydopamine-coated melamine resin sponge

[0039] Soak the pre-cut melamine resin sponge in 500ml of alkaline buffer solution with a pH value of 8, then add 1.6g of dopamine hydrochloride, and stir or shake evenly for 10 hours. When the reaction time is up, take it out, then wash it three times with deionized water, and let it dry.

[0040] (2) Modification of polydopamine-coated melamine resin sponge

[0041] Soak the polydopamine-coated melamine resin sponge in an alkaline ethanol solution with a pH value of 8.5 containing 2 g / L of mercaptofluoroalkane (30 carbons), and stir or shake it evenly for 24 hours. After reaching the reaction time, take it out, wash it twice with ethanol, and then dry it to obtain the extrusion-resistant, fireproof and superhydrophobic sponge. The prepared material is referred to as material 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com