Fuel oil deep-desulfurization method based on organic rhenium catalyst

A catalyst and fuel oil technology, applied in the petroleum industry, refined hydrocarbon oil, etc., can solve problems such as secondary pollution, high operating costs, and large equipment investment, and achieve obvious effects, simple processes, and high value-added utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

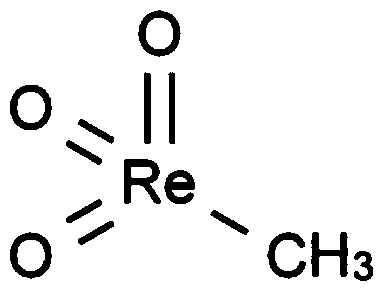

[0012] Embodiment 1: commercially available 93# gasoline desulfurization

[0013] 1) Preparation of the fixed bed: mix methyl rhenium trioxide and white clay uniformly at a mass ratio of 1:5, then add molten sucrose in an equal proportion (total weight of the mixture of methyl rhenium trioxide and white clay), stir evenly, and Under certain conditions, apply it on the fixed bed mesopores, wash it several times with chloroform after it hardens, put it in a furnace and sinter at 300 ° C for 3 hours, cool down, and place the fixed bed coated with organic rhenium catalyst on the jacket of the reactor in the inner tube.

[0014] 2) Put the gasoline into the storage tank. 3 The flow rate per hour is injected into the jacketed inner tube of the reactor, flows through the fixed bed, controls the temperature of the reactor at 20°C, collects the outflowing oil into the finished product tank, and completes the desulfurization of gasoline. The obtained product is tested, and the sulfur c...

Embodiment 2

[0015] Embodiment 2: Desulfurization of commercially available 0# diesel oil

[0016] 1) Preparation of the fixed bed: mix methyl rhenium trioxide and white clay uniformly at a mass ratio of 1:3, then add molten sucrose in equal proportions, stir evenly, and apply it on the mesoporous surface of the fixed bed under the condition of ultrasonic resonance. After hardening, it was washed several times with chloroform, put into a furnace for sintering at 300°C for 3 hours, cooled, and the fixed bed was put into a jacketed reactor.

[0017] 2) Put the diesel oil into the storage tank, and after the oil product has stood still, under normal pressure, put the diesel oil at 50m 3 The flow rate per hour is injected into the jacketed inner tube of the reactor, flows through the fixed bed, controls the temperature of the reactor at 65°C, collects the outflowing oil into the finished product tank, and completes the desulfurization of diesel oil. The obtained product is tested and the sulfu...

Embodiment 3

[0018] Example 3: Gasoline desulfurization of a petrochemical company

[0019] 1) Preparation of the fixed bed: mix methyl rhenium trioxide and white clay evenly at a mass ratio of 1:2, then add molten sucrose in equal proportions, stir evenly, and apply it on the mesoporous surface of the fixed bed under the condition of ultrasonic resonance. After hardening, it was washed several times with chloroform, put into a furnace and sintered at 300°C for 3 hours, cooled, and the fixed bed coated with organic rhenium catalyst was placed in the jacketed inner tube of the reactor.

[0020] 2) Put the oil into the storage tank, and after the oil has stood still, put the oil under normal pressure at 20m 3 The flow rate per hour is injected into the jacketed inner tube of the reactor, flows through the fixed bed, controls the temperature of the reactor at 80°C, collects the outflowing oil into the finished product tank, and completes the desulfurization of gasoline. The obtained product i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com