Method for preparing trehalose

A technology of trehalose and trehalose hydrolase, applied in the direction of fermentation, etc., can solve the problems of long conversion time and improvement of conversion efficiency, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

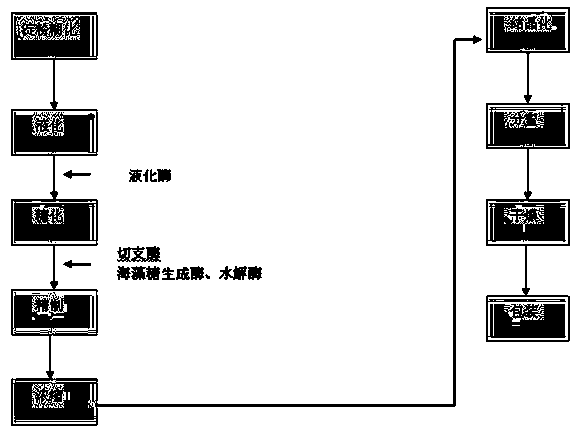

Method used

Image

Examples

Embodiment 1

[0041] 1) Starch gelatinization: Stir the starch with water at 50°C to adjust the pH to 6.4-8; the ratio of starch to water is 1:30.

[0042] 2) Liquefaction: α-amylase is used to catalyze the hydrolysis liquefaction reaction. The activity unit of the α-amylase is 5000U / g, and the dosage is 5-6g α-amylase / 100g starch; the secondary jet liquefaction method is adopted, and the starch The paste concentration is 32%, ph6.5, spraying temperature once is 105°C, and spraying temperature is 125°C twice, spraying pressure is 0.2-0.4mPa, keep warm at 96°C for 30min; inactivate enzyme.

[0043] 3) Saccharification: Add 3000U of isoamylase to each liter of starch hydrolyzate after liquefaction, and inactivate the enzyme after the reaction is completed.

[0044] Add maltooligosaccharide-based trehalose synthase and maltooligosaccharide-based trehalose hydrolase to the obtained hydrolyzate; add 300 U maltooligosaccharide-based trehalose synthase and 600 U hydrolase to each liter of starch h...

Embodiment 2

[0053] 1) Starch gelatinization: Stir the starch with water at 60°C to adjust the pH to 8; the ratio of starch to water is 1:25.

[0054] 2) Liquefaction: use α-amylase to catalyze the hydrolysis liquefaction reaction, the activity unit of the α-amylase is 3000U / g, and the dosage is 5-6g α-amylase / 100g starch; the secondary jet liquefaction method is used, and the starch The paste concentration is 32%, ph6.5, spraying temperature once is 105°C, and spraying temperature is 125°C twice, spraying pressure is 0.2-0.4mPa, keep warm at 100°C for 60min; inactivate the enzyme.

[0055] 3) Saccharification: Add 3000U of isoamylase to each liter of starch hydrolyzate after liquefaction, and inactivate the enzyme after the reaction is completed.

[0056] Add maltooligosaccharide-based trehalose synthase and maltooligosaccharide-based trehalose hydrolase to the obtained hydrolyzate; add 500 U maltooligosaccharide-based trehalose synthase and 500 U hydrolase to each liter of starch hydroly...

Embodiment 3

[0064] 1) Starch gelatinization: Stir the starch with water at 55°C to adjust the pH to 6.4; the ratio of starch to water is 1:29.

[0065] 2) Liquefaction: use α-amylase to catalyze the hydrolysis liquefaction reaction, the activity unit of the α-amylase is 4000U / g, and the dosage is 5-6g α-amylase / 100g starch; the secondary jet liquefaction method is used, and the starch The paste concentration is 32%, ph6.5, spraying temperature once is 105°C, and spraying temperature is 125°C twice, spraying pressure is 0.2-0.4mPa, keep warm at 97°C for 42min; inactivate enzyme.

[0066] 3) Saccharification: Add 3000U of isoamylase to each liter of starch hydrolyzate after liquefaction, and inactivate the enzyme after the reaction is completed.

[0067] Add maltooligosaccharide-based trehalose synthase and maltooligosaccharide-based trehalose hydrolase to the obtained hydrolyzate; add 300 U maltooligosaccharide-based trehalose synthase and 600 U hydrolase per liter of starch hydrolyzate; c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com