Fluorocarbon-doped ferroferric oxide used as lithium battery anode material and preparation method thereof

A technology of ferric tetroxide and hollow ferric tetroxide, which is applied to battery electrodes, ferrous oxides, iron oxides/ferric hydroxides, etc. , It is difficult to solve the problems of lithium-ion batteries, etc., to achieve good industrial application prospects, excellent specific capacity performance, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

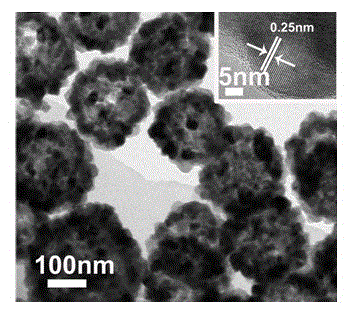

[0032] Preparation of Fe3O4 material: Add 800mL of deionized water to a 1L beaker, add 10.8g of Ferric Chloride, 23.5g of Sodium Citrate and 7.2g of urea under magnetic stirring conditions, and stir After half an hour, after all the added substances are dissolved, then weigh 6g of polyacrylamide and slowly add it to the above solution, continue to stir for one and a half hours, then transfer the mixed solution to the reaction kettle, and react at 200°C for 12h. Take out the reaction kettle, wash it repeatedly with deionized water and absolute ethanol after the reaction is cooled, and finally dry it overnight in a vacuum oven at 70°C to obtain hollow iron ferric oxide.

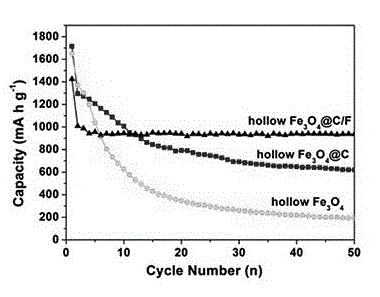

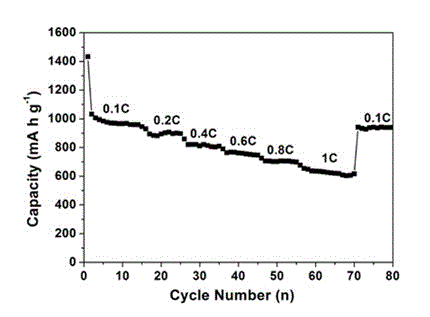

[0033]Preparation of carbon layer-coated porous and hollow iron ferric oxide: add the obtained hollow ferric iron tetroxide to 400mL 0.5M aqueous glucose solution, and after all the solutions are dissolved, transfer the solution to a 1000mL reaction kettle. Reaction at 180°C for 6h. Take out the reaction kettl...

Embodiment 2

[0039] The preparation of the ferroferric oxide material is the same as in Example 1, except that the sample mixed with polyvinylidene fluoride is burned at 420° C. for 4 hours.

[0040] The battery performance test method is the same as that in Example 1, and the discharge specific capacity of the obtained battery after charging and discharging for 50 cycles at a rate of 0.1C is 820mAh / g.

Embodiment 3

[0042] The preparation of the ferroferric oxide material is the same as in Example 1, except that the sample mixed with polyvinylidene fluoride is burned at 450° C. for 4 hours.

[0043] The battery performance test method is the same as that of Example 1, and the discharge specific capacity of the obtained battery after charging and discharging for 50 cycles at a rate of 0.1C is 860mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com