Preparation method of halogen-doped carbon and silicon nano-material and application thereof

A nanomaterial and silicon nanotechnology, applied in the field of lithium-ion batteries, can solve problems such as difficult to meet the performance of high-performance lithium-ion batteries, complex preparation process, etc., achieve excellent battery performance and service life, simple preparation method, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

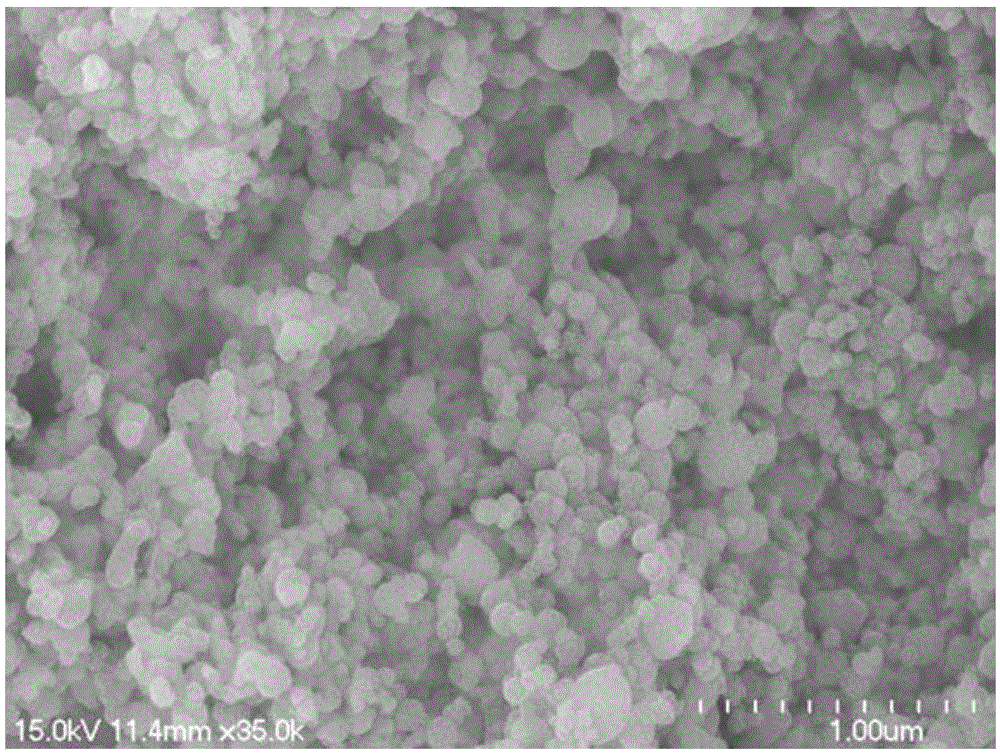

[0021] Evenly disperse 10g of silicon nanoparticles and 10g of carbon source into 200mL of ethanol solution, wherein the molar ratio of polyvinylidene fluoride, polyvinylidene chloride and polytetrafluoroethylene is 1:2:1, after stirring evenly, ball mill for 3 hours , put into 100 ℃ oven and dry for 12h. Finally, carbonize in a nitrogen atmosphere at a heating rate of 5°C / min, heat up to 800°C for 2 hours, and obtain a halogen-doped carbon-silicon nanomaterial after cooling.

[0022] Electrochemical performance test:

[0023] The prepared materials were uniformly mixed with SuperP and PVDF in N-methylpyrrolidone solution at a mass ratio of 8:1:1, and then evenly coated on copper foil and dried in vacuum at 120 °C. With EC / DEC=1:1LiPF 6 It is the electrolyte, PP is the diaphragm, and the metal lithium sheet is the counter electrode. A button battery is made in a glove box filled with argon. Test the charge and discharge performance of the assembled battery on the LAND batte...

Embodiment 2

[0025] The preparation example 1 of the halogen-doped carbon-silicon nanomaterial is basically the same, except that the mixed sample is kept at 900° C. for 2 hours.

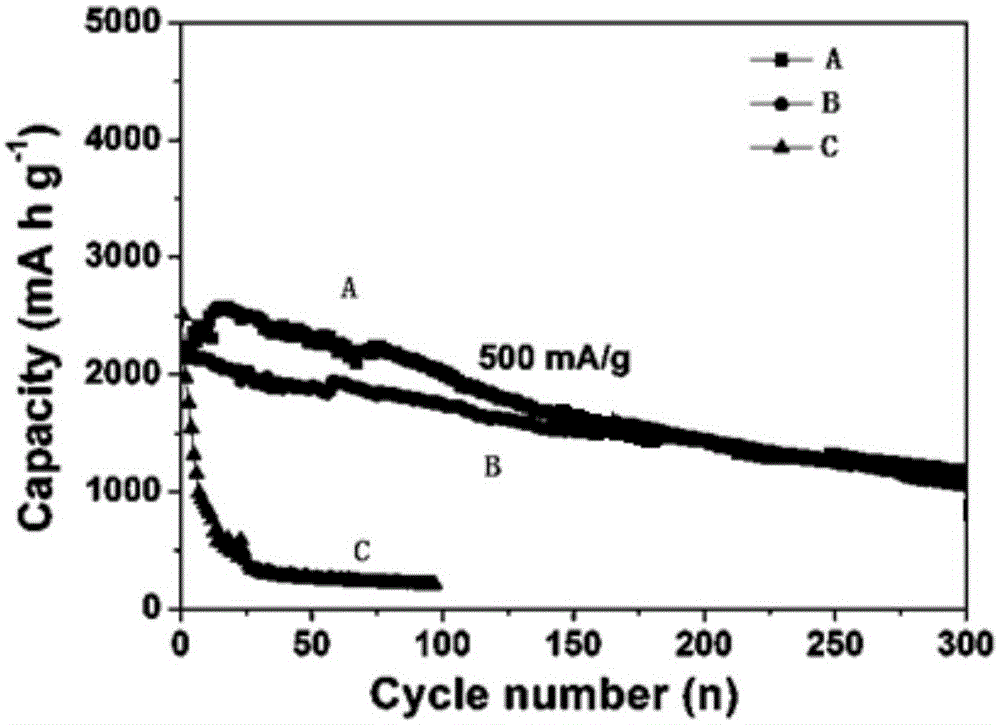

[0026] Battery performance testing method is identical with embodiment one, and the discharge specific capacity of gained battery is respectively about 1100mAh / g after cycling 300 circles under the electric current density of 500mA / g, is far higher than simple silicon nano material electrode material (450mAh / g ).

Embodiment 3

[0028] The preparation example 1 of halogen-doped carbon-silicon nanomaterials is basically the same, except that the mass ratio of silicon nanomaterials to carbon source is 1:2, and the polyvinylidene fluoride, polyvinylidene chloride and polytetrafluoroethylene added in the actual experiment The mass is 20g. The battery performance test method is the same as that of Example 1, and its discharge specific capacity and cycle relation curve are shown in figure 2 (B), the discharge specific capacity of the obtained battery after 300 cycles at a current density of 500mA / g is about 1300mAh / g, and the cycle stability is much higher than that of a single silicon nanomaterial (450mAh / g).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com