CMOS image sensor structure for realizing predictive coding image compression

An image sensor and predictive coding technology, applied in image communication, color TV parts, TV system parts, etc., can solve problems such as difficult to meet area requirements and low precision of analog circuits, and achieve low power consumption, Eliminates offset, low area effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

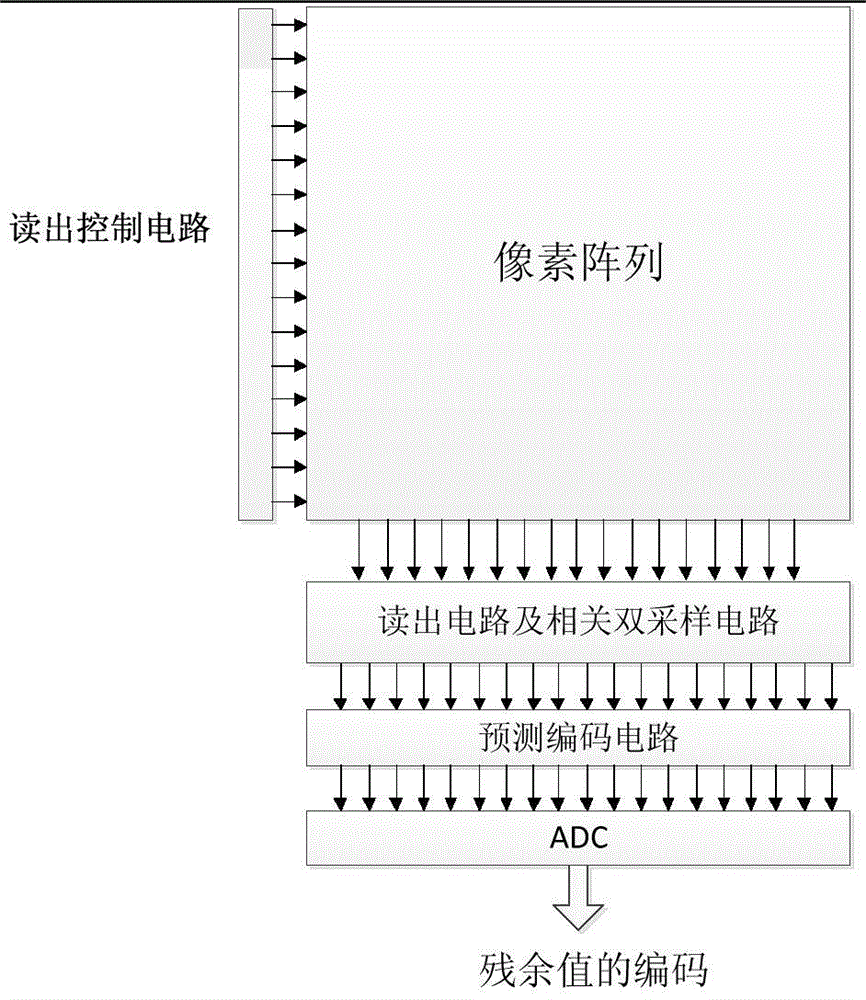

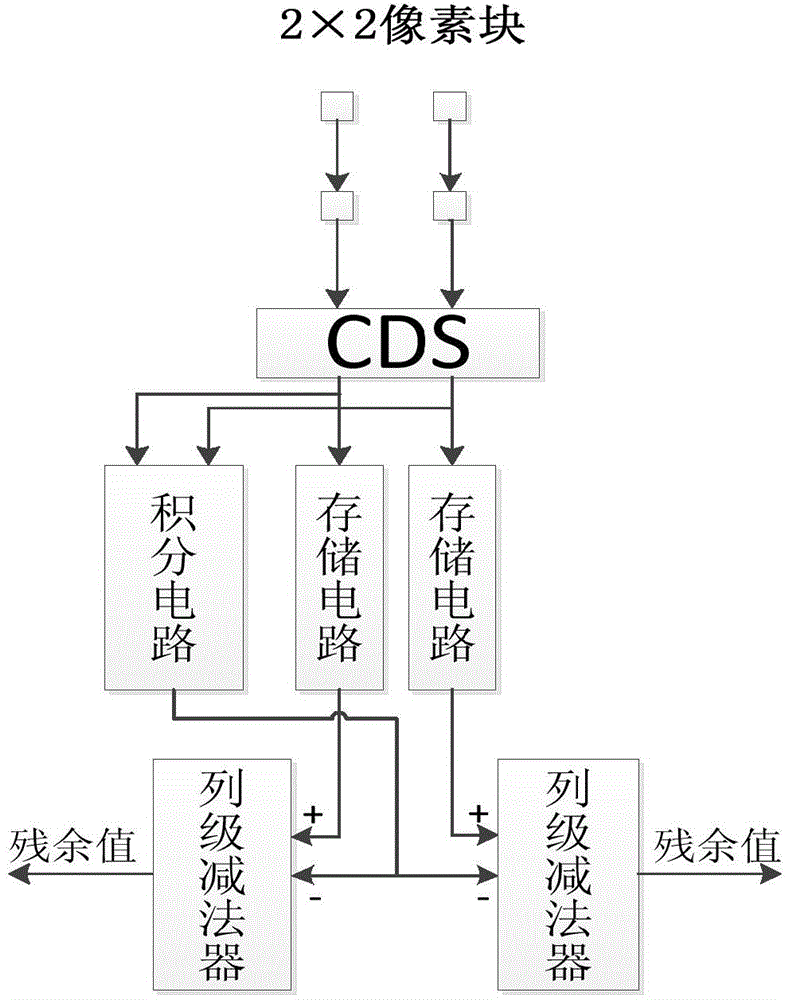

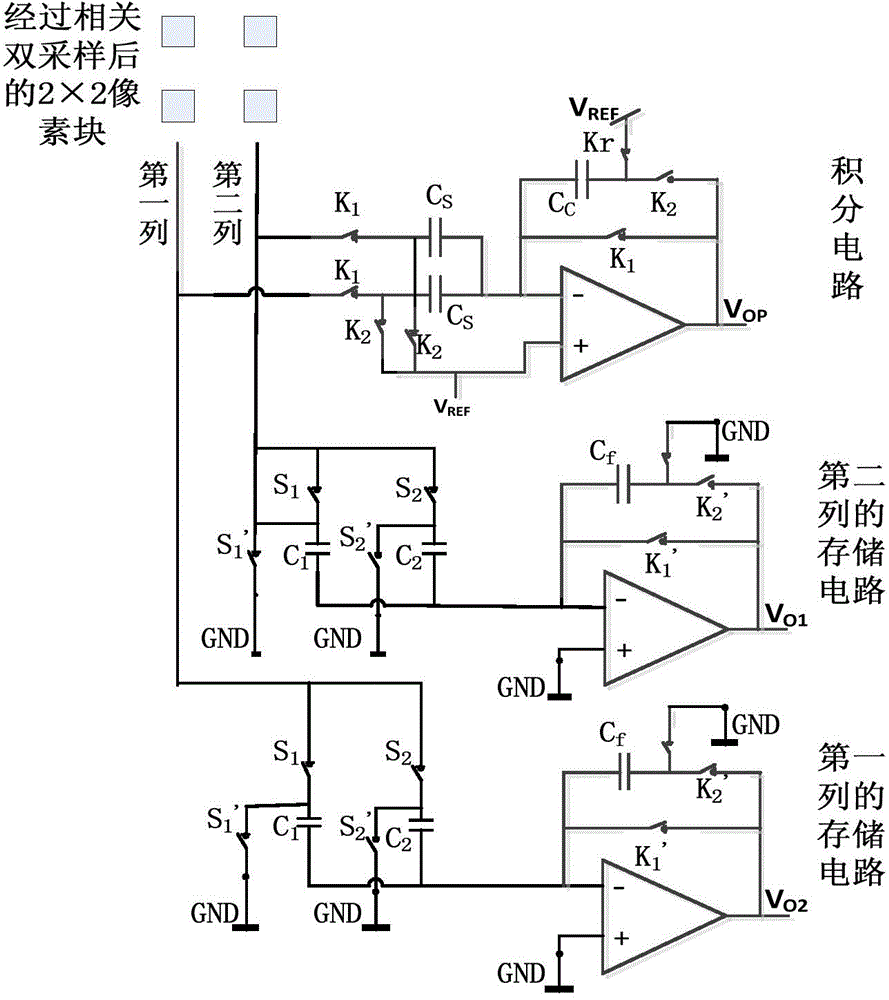

[0014] In order to reduce the circuit complexity of the chip and improve the processing efficiency, the predictive coding operation is completed in the analog domain. The invention provides a CMOS image sensor structure capable of realizing predictive coding image compression. It is composed of pixel array, readout and correlated double sampling circuit, predictive encoding circuit, analog to digital converter (analog to digital converter, ADC) and timing control circuit, see figure 1 . The pixel values read out from the pixel array are first sent to the correlated double sampling (CDS) circuit for correlated double sampling to eliminate fixed pattern noise, and then the predictive coding circuit will perform prediction value under the control of the sequential circuit. The calculation operation, after obtaining the predicted value, the column-level subtractor will be used to obtain the difference between the predicted value and the original pixel value, that is, the residu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com