Preparation method of molecular sieve-containing catalyst

A molecular sieve and catalyst technology, applied in the field of catalyst preparation, can solve problems such as singleness and unavoidable shortcomings, and achieve the effects of increasing selectivity, good selectivity and activity stability, and increasing loading capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The invention provides a method for preparing a catalyst containing molecular sieve, which is characterized in that it includes the step of modifying molecular sieve and the step of introducing matrix, and the step of modifying molecular sieve is to use molecular sieve, one selected from water, alcohol and ester After mixing one or more kinds of substances and organic bases evenly, they are treated in a sealed reaction kettle at 100-250°C under autogenous pressure, and the products obtained from the treatment are recovered, and then exchanged with rare earth ion salts.

[0016] In the preparation method provided by the present invention, wherein said step of modifying molecular sieves, this step comprises mixing molecular sieves, one or more substances selected from water, alcohols, esters, and organic bases uniformly, and then It is treated at 100-250°C under autogenous pressure, and the product obtained from the treatment is recovered, and then exchanged with rare eart...

Embodiment 1

[0031] This example illustrates the modification step of β molecular sieve in the method provided by the present invention.

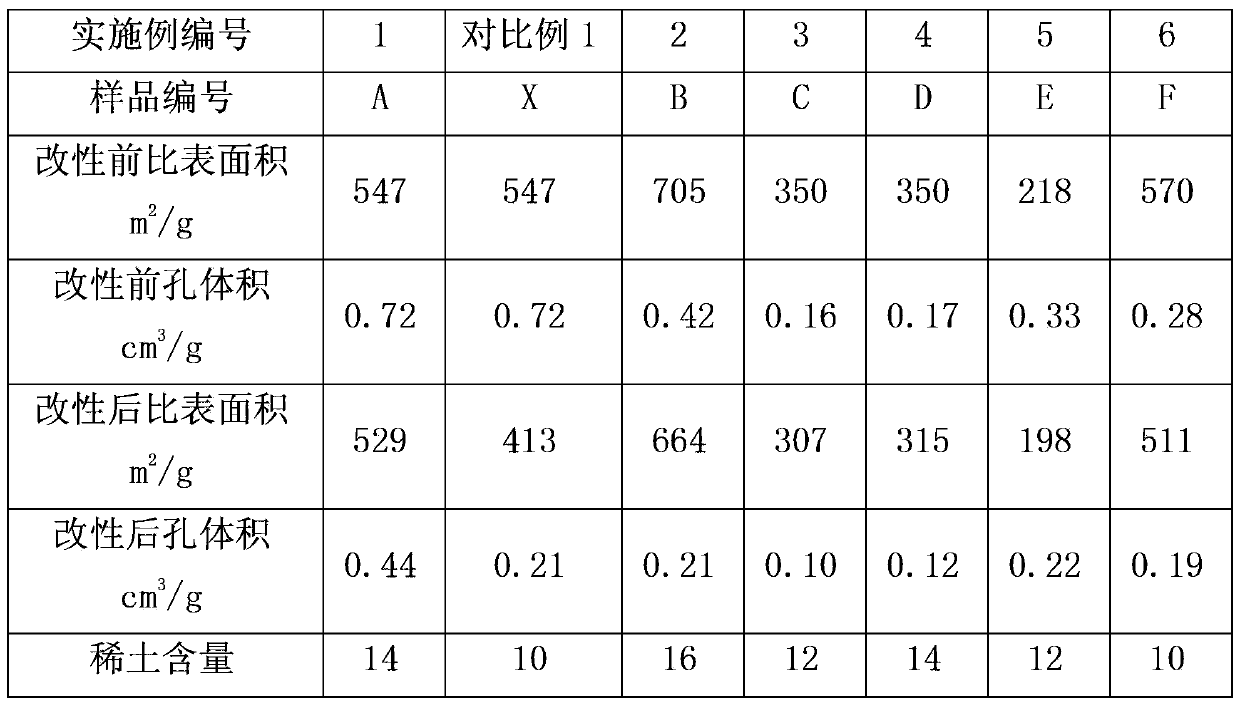

[0032] 10g β molecular sieve (provided by Zhoucun Catalyst Factory, SiO 2 / Al 2 o 3 =25,Na 2 O%<0.1%, roasting at 550°C for 2h) Add 10g of diethylamine and 50g of ethanol, add them to the pressure melting bomb, and heat at 120°C for 24h. Suction filter, wash, and dry the obtained sample at 110°C, then add 5 g of the above-mentioned organic base modified sample to 300 g of water, add 40 g of lanthanum nitrate hexahydrate, exchange at 50°C for 5 hours, wash and suction filter, and dry at 110°C, the obtained The sample is counted as A, and the results of XRD and BET characterization are listed in Table 1.

Embodiment 2

[0037] This example illustrates the modification steps of the Y-type molecular sieve in the method provided by the present invention.

[0038] 10g Y molecular sieve (provided by Changling Catalyst Factory, SiO 2 / Al 2 o 3 =5,Na 2 O%<0.1%, roasting at 550°C for 2h) Add 10g of triethylamine and 50g of methanol, add them to the pressure melting bomb, and heat at 120°C for 144h. Suction filter, wash, and dry the obtained sample at 110°C, then add 5 g of the above-mentioned organic base modified sample to 200 g of water, add 30 g of cerium nitrate hexahydrate, exchange at 60°C for 4 hours, wash and suction filter, and dry at 110°C, the obtained The sample is counted as B, and the results of XRD and BET characterization are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com