Molecular sieve containing rare earth elements and preparation method thereof

A rare earth element and molecular sieve technology, which is applied in the field of preparation of molecular sieve catalytic materials, can solve the problems of high sodium oxide content, high production energy consumption, long exchange cycle and production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

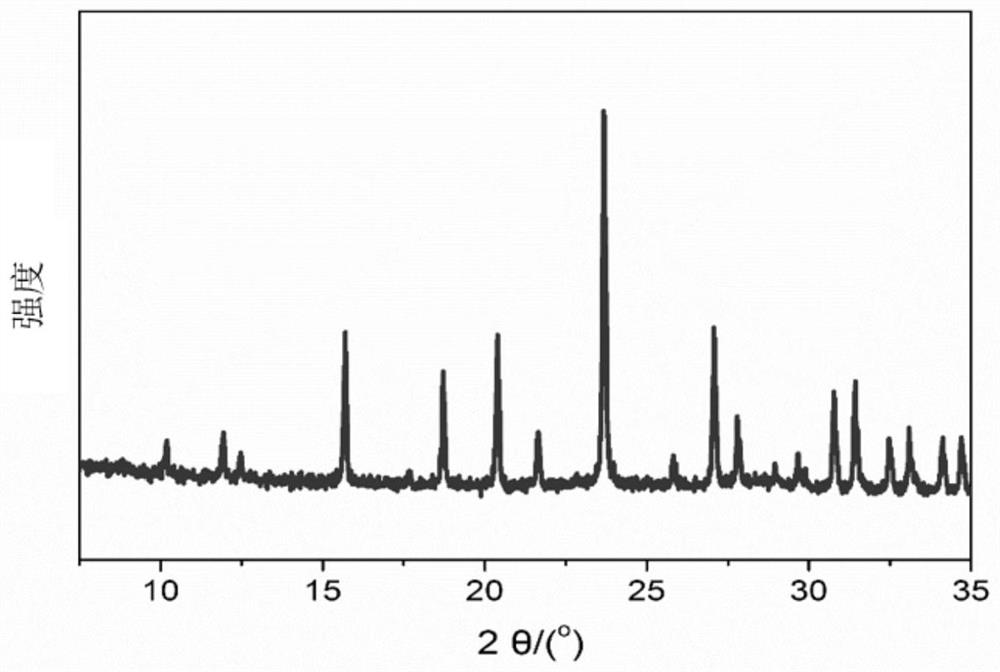

Image

Examples

preparation example Construction

[0048] The first aspect of the invention provides a preparation method of molecular sieve containing rare earth elements, wherein the method comprises:

[0049] 1) Under microwave conditions, the sodium molecular sieve and the solution containing rare earth element ions are subjected to the first ion exchange reaction to obtain the molecular sieve after rare earth element ion exchange;

[0050] 2) Roasting the molecular sieve obtained in step 1) after ion exchange of rare earth elements to obtain the roasted molecular sieve;

[0051] 3) The molecular sieve calcined in step 2) is subjected to the second ion exchange reaction with the solution containing ammonium ions to obtain the molecular sieve containing rare earth elements.

[0052] The inventor of the invention found that, firstly, the sodium ions in the sodium molecular sieve are exchanged with rare earth elements under microwave conditions, and then the residual sodium ions in the molecular sieve are further exchanged with a...

Embodiment 1

[0086] 1) Mix NaY molecular sieve with aqueous solution containing lanthanum chloride and cerium chloride. The weight ratio of water to NaY molecular sieve is 20:1, and the weight ratio of total lanthanum chloride and cerium chloride to NaY molecular sieve is 0.8:1. Adjust the pH to 4.5 with dilute hydrochloric acid solution (concentration is 5 wt%). After that, the obtained mixture is placed under microwave conditions for the first ion exchange. The microwave conditions include: the frequency is 2450MHz, the microwave power is 1.5KW, the temperature is raised from 25 ℃ to 220 ℃, the microwave heating time is 5min, and it is maintained at the exchange temperature for 5min. After the exchange, the product was filtered, washed with 6 times the volume of deionized water, and then dried at 120 ℃ for 6h to obtain the molecular sieve after ion exchange of rare earth elements;

[0087] 2) Calcine the rare earth element ion exchanged molecular sieve obtained in step 1) at 550 ℃ for 3h to ...

Embodiment 2

[0091] 1) Mix NaY molecular sieve with aqueous solution containing lanthanum chloride and cerium nitrate. The weight ratio of water to NaY molecular sieve is 15:1, and the weight ratio of total amount of lanthanum chloride and cerium nitrate to NaY molecular sieve is 0.5:1. Adjust the pH to 4.5 with dilute hydrochloric acid solution (concentration is 5 wt%). After that, the obtained mixture is placed under microwave conditions for the first ion exchange. The microwave conditions include: the frequency is 2450MHz, the microwave power is 0.5KW, the temperature is raised from 25 ℃ to the exchange temperature 181 ℃, the microwave heating time is 5min, and it is maintained at the exchange temperature for 25min. After the exchange, the product was filtered, washed with 6 times the volume of deionized water, and then dried at 120 ℃ for 6h to obtain the molecular sieve after ion exchange of rare earth elements;

[0092] 2) Calcine the rare earth element ion exchanged molecular sieve obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com