Modification method and rare earth Y-type molecular sieve

A molecular sieve and rare earth technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as difficult sodalite cages, and achieve simple implementation, reduced coke selectivity, and improved proximity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 100g NaY molecular sieve and 1800g deionized water, mix and beat, add 20ml concentration to 357gRE 2 o 3 / L of rare earth chloride salt solution and 2g of ammonium chloride solid, stir well, raise the temperature to 70°C and adjust the pH value of the slurry to 4.5 with dilute hydrochloric acid, and stir at constant temperature for 1h. After filtering, washing with water, and drying, load 7g of ammonia water by impregnation method, after drying, pressurized hydrothermal roasting at 500°C, 0.3Mpa, and 100% water vapor atmosphere for 2h to obtain rare earth sodium Y molecular sieve, which is designated as PCY-1.

[0024] In the chemical composition of PCY-1, the rare earth oxide was 10.1% by weight.

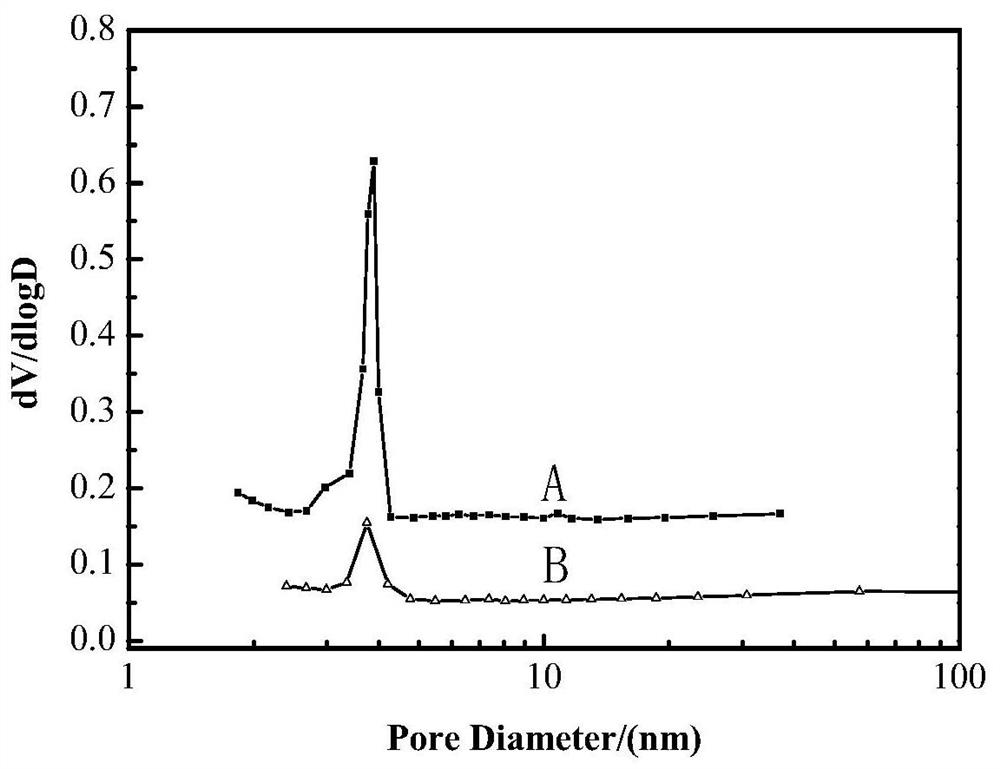

[0025] figure 1 The middle A curve is the pore size distribution curve of sample PCY-1 calculated according to the BJH model. from figure 1 It can be seen from the curve A that there are at least two kinds of mesoporous pore size distributions, which are respectiv...

Embodiment 2

[0044] Get 100g NaY molecular sieve (Sinopec Catalyst Company Changling Branch, caustic soda 74.1% by weight, crystallinity 89.3%, the same below) and 1000g deionized water are mixed and beaten, add 16ml concentration to be 357gRE 2 o 3 / L of rare earth chloride salt solution and 8g of ammonium chloride solid, stir well, raise the temperature to 60°C and adjust the pH value of the slurry to 4.0 with dilute hydrochloric acid, and stir at constant temperature for 1.5h.

[0045] After filtering, washing with water, and drying, load 10g of ammonium chloride by impregnation method, and after drying, roast for 0.5h at 430°C, with an apparent pressure of 0.8Mpa and a 100% water vapor atmosphere to obtain a NaY molecular sieve containing rare earths. The sample number is marked for PCY-2.

[0046] The chemical composition of PCY-2 molecular sieve is 8.0% by weight of rare earth oxide.

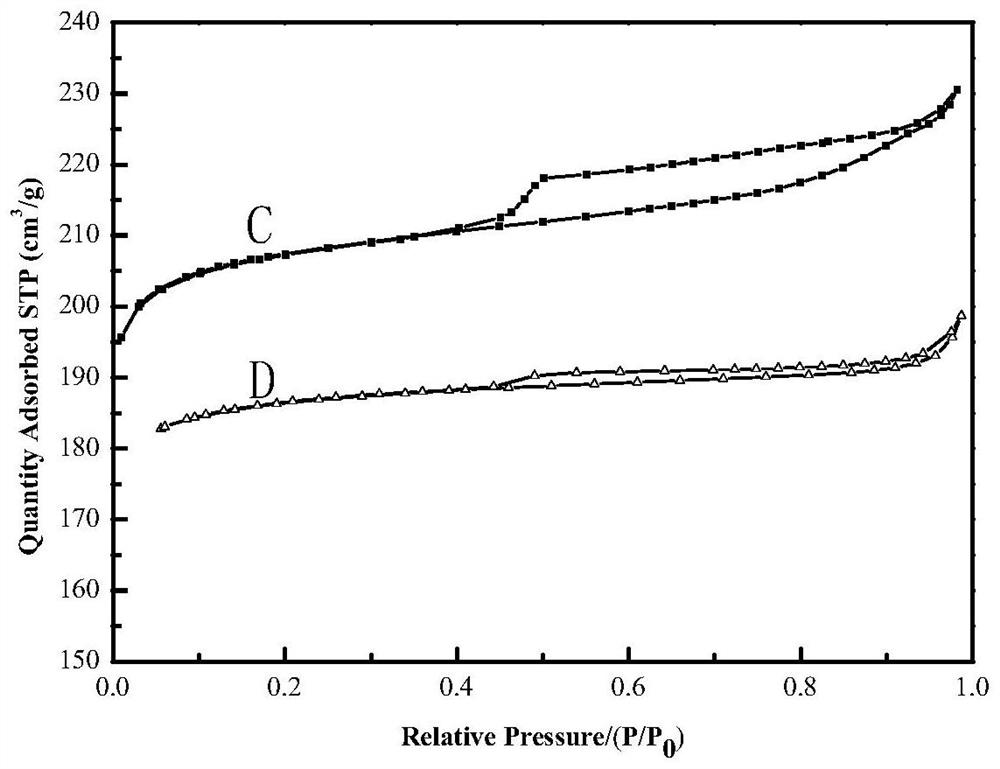

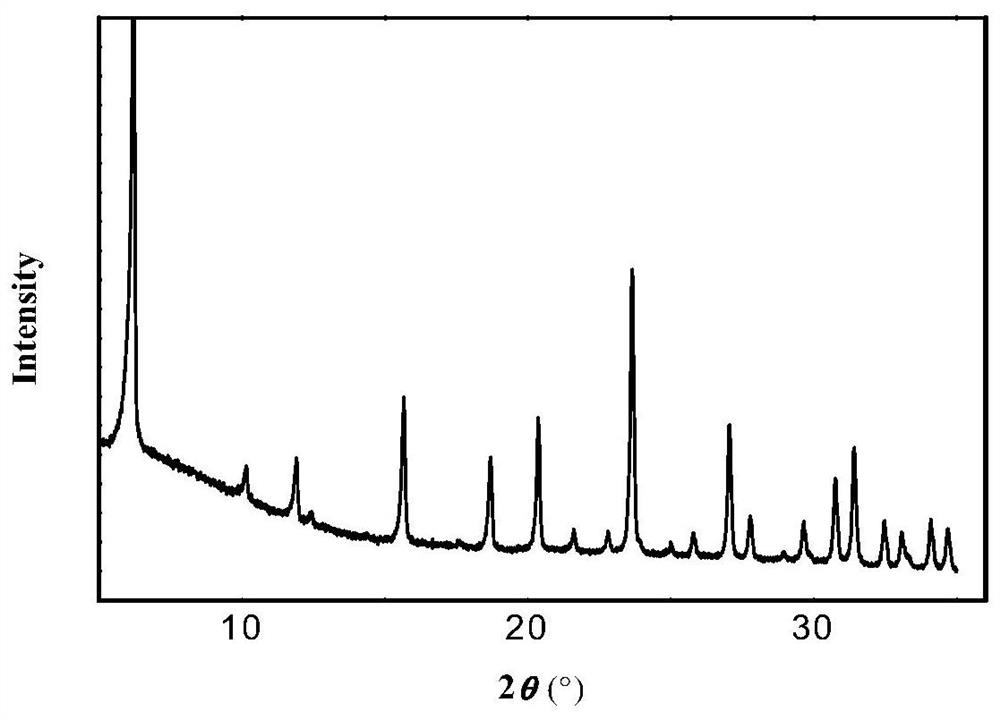

[0047] The BJH pore size distribution curve, adsorption-desorption curve and XRD spectrum of PCY-...

Embodiment 3

[0050] Take 100g NaY molecular sieve and 2200g deionized water, mix and make slurry, add 24ml concentration to 357gRE 2 o 3 / L of rare earth chloride salt solution, stir well, heat up to 70°C, adjust the pH value of the slurry to 3.5 with dilute hydrochloric acid, and stir at constant temperature for 1 hour. After filtering, washing with water and drying, load 12g of ammonium bicarbonate by impregnation method, after drying, pressurized hydrothermal calcination at 520°C, 0.4Mpa, 100% water vapor atmosphere for 1.5h to obtain rare earth NaY molecular sieve, which is denoted as PCY- 3.

[0051] The chemical composition of PCY-3 molecular sieve is 10.7% by weight of rare earth oxide.

[0052] The BJH pore size distribution curve, adsorption-desorption curve and XRD spectrum of PCY-3 are the same as figure 1 A curve, figure 2 C curve and image 3 Characteristics.

[0053] The XRD results and pore parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com