Method for synthesizing phosphotungstic acid-titanium dioxide composite spherical nanomaterials by one-step sol-gel method

A technology of titanium dioxide and synthesis methods, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, nanotechnology, etc., can solve the problems of complex preparation methods and unresolved energy consumption, and achieve simple preparation methods , less equipment energy consumption, and the effect of simplifying the experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) 0.6g tetrabutyl titanate ([C 4 h 9 0] 4 Ti) drop into 50mL absolute ethanol, stir vigorously;

[0018] 2) Add 1 mL of absolute ethanol solution containing 0.135 g of phosphotungstic acid drop by drop;

[0019] 3) Continue to stir and add 1ml of a mixed solution of water and ethanol (v / v=1:5) dropwise, and continue to stir and react at room temperature for 4h;

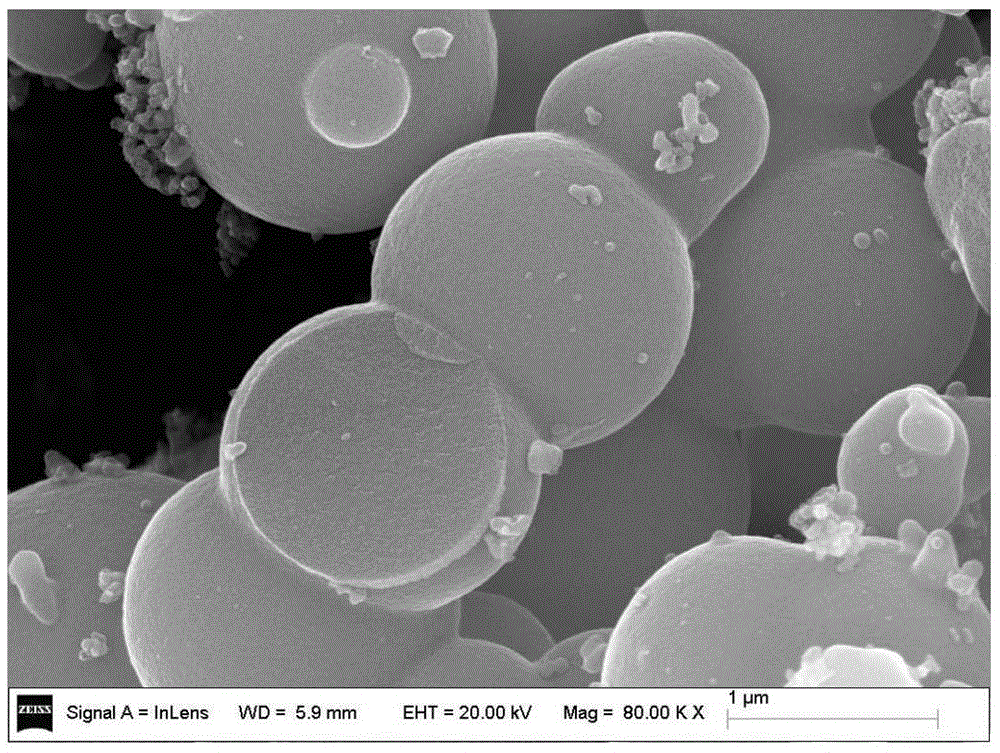

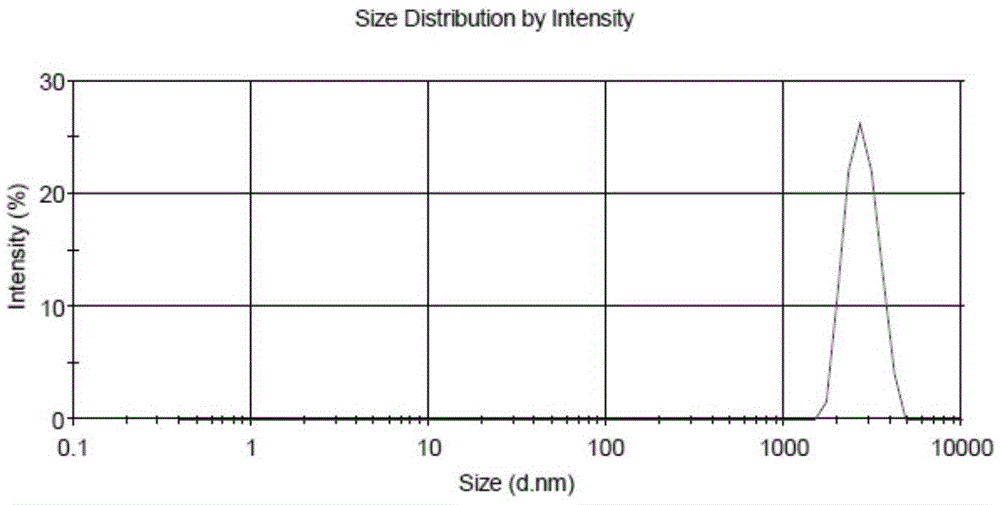

[0020] 4) Centrifuge to obtain a white precipitate, wash it twice with water and ethanol respectively, dry it in an oven at 70°C for 4 hours, and then dry it in a muffle furnace at 150°C for 3 hours to obtain a composite spherical nanomaterial of phosphotungstic acid-titanium dioxide. It has a spherical cluster structure, and the mass ratio of phosphotungstic acid and titanium dioxide is 1:10.

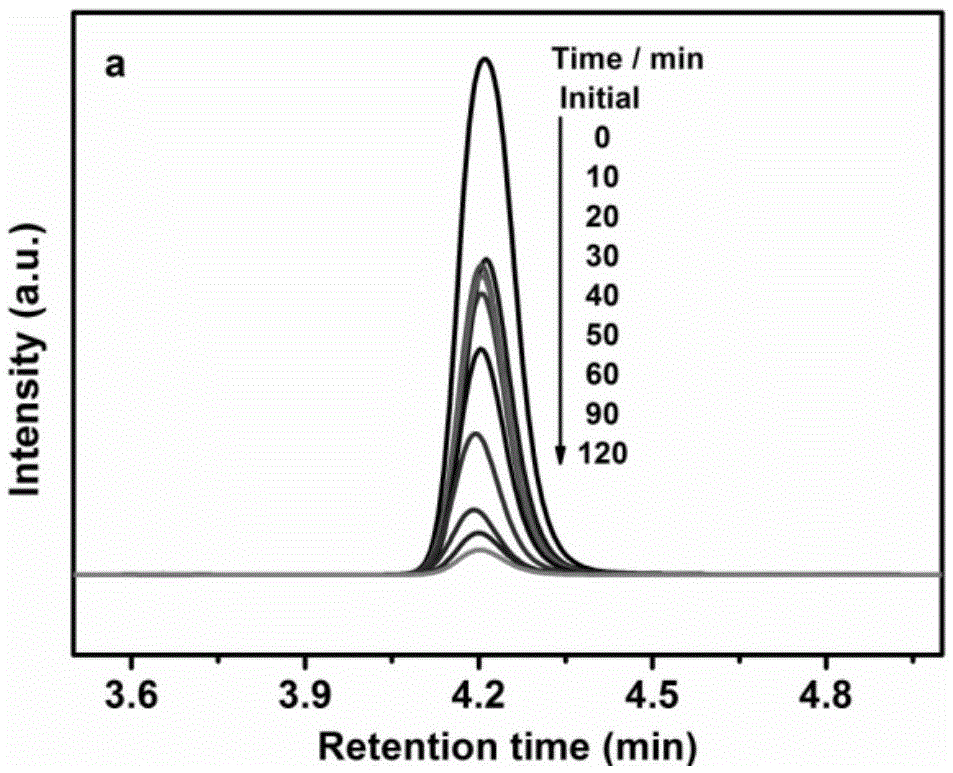

[0021] Prepare 20 mL of DBT n-octane solution with a sulfur content of 350 ppm, add it to a 100 mL three-necked round-bottom flask, add 20 mL of acetonitrile as an extraction agent, and weigh 70 mg of the prepared ...

Embodiment 2

[0023] 1) 0.6g tetrabutyl titanate ([C 4 h 9 0] 4 Ti) drop into 50mL absolute ethanol, stir vigorously;

[0024] 2) Add 1 mL of absolute ethanol solution containing 0.653 g of phosphotungstic acid drop by drop;

[0025] 3) Continue to stir and add 1ml of a mixed solution of water and ethanol (v / v=1:5) dropwise, and continue to stir and react at room temperature for 4h;

[0026] 4) Centrifuge to obtain a white precipitate, wash it twice with a small amount of water and ethanol, dry it in an oven at 70°C for 4 hours, and then dry it in a muffle furnace at 150°C for 3 hours to obtain phosphotungstic acid-titanium dioxide composite spherical nanomaterials. The material has a spherical cluster structure, and the mass ratio of phosphotungstic acid and titanium dioxide is 3:10.

[0027] Prepare 20 mL of DBT n-octane solution with a sulfur content of 350 ppm, add it to a 100 mL three-necked round-bottom flask, add 20 mL of acetonitrile as an extraction agent, and weigh 70 mg of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com