Internal cooling grinding wheel

A grinding wheel and grinding technology, applied in the field of grinding tools, can solve the problems of difficult nozzle or coolant supply, limited gas cooling effect, low penetration efficiency, etc., and achieve the effect of reducing temperature, avoiding grinding burns, and fully cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

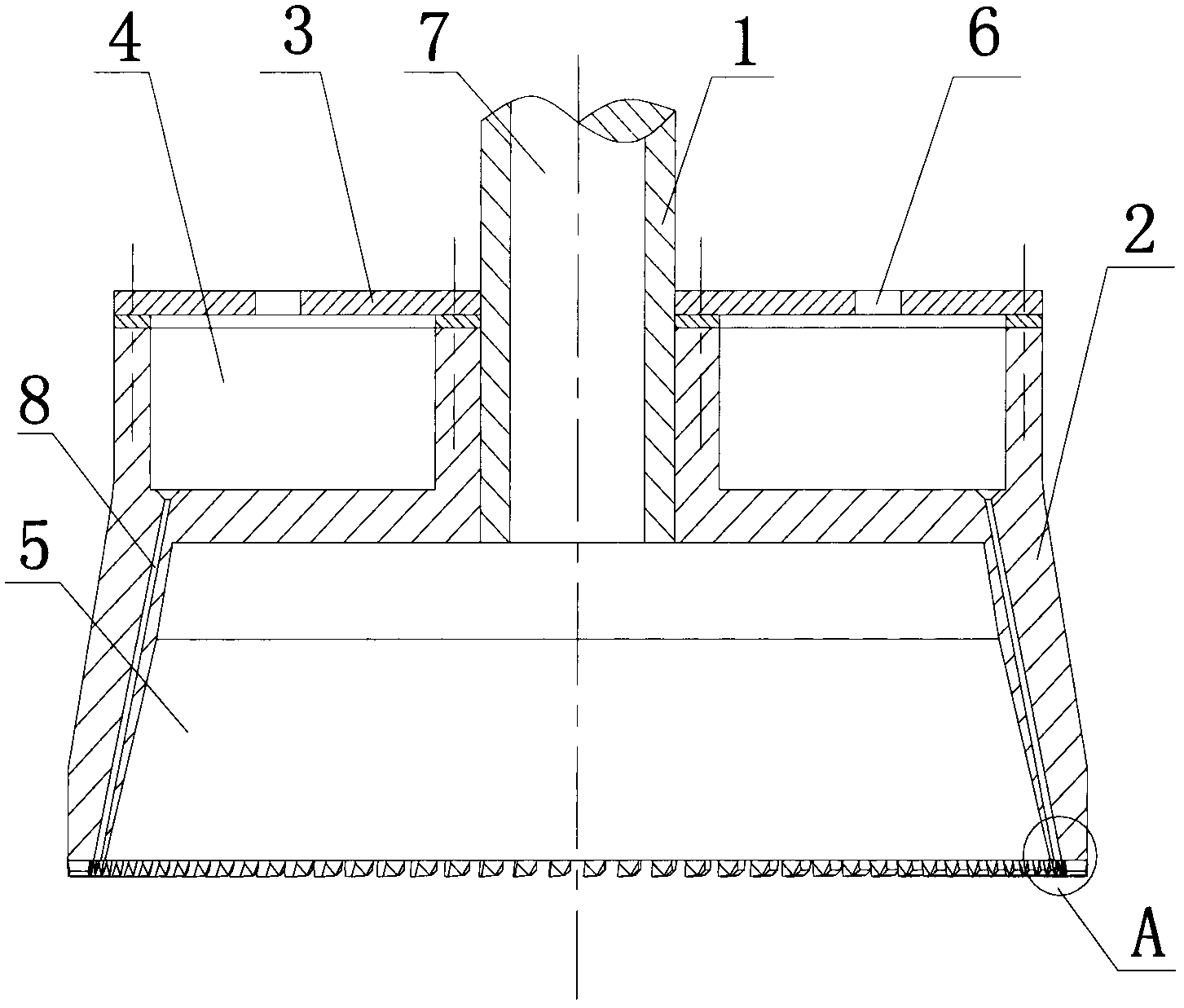

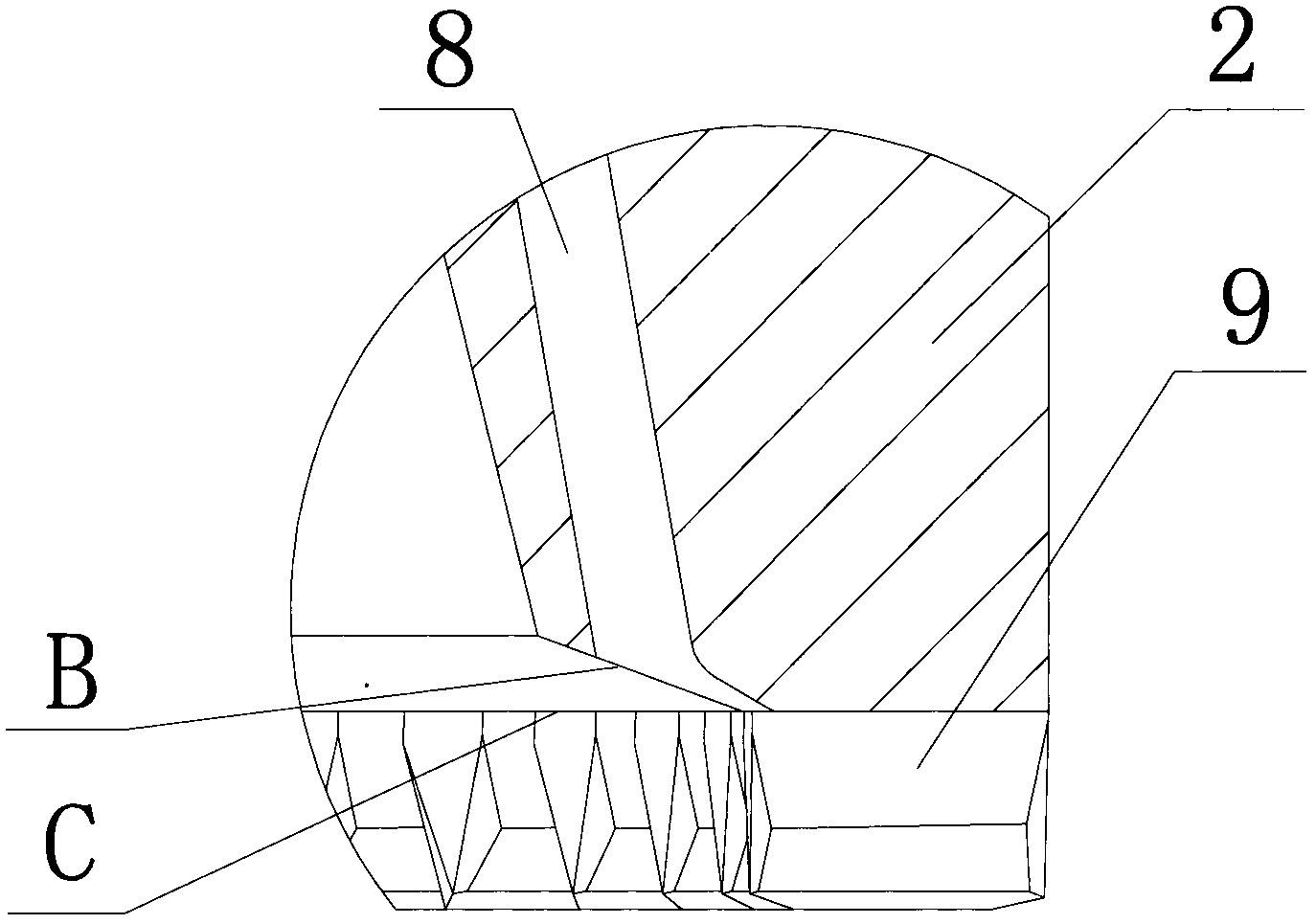

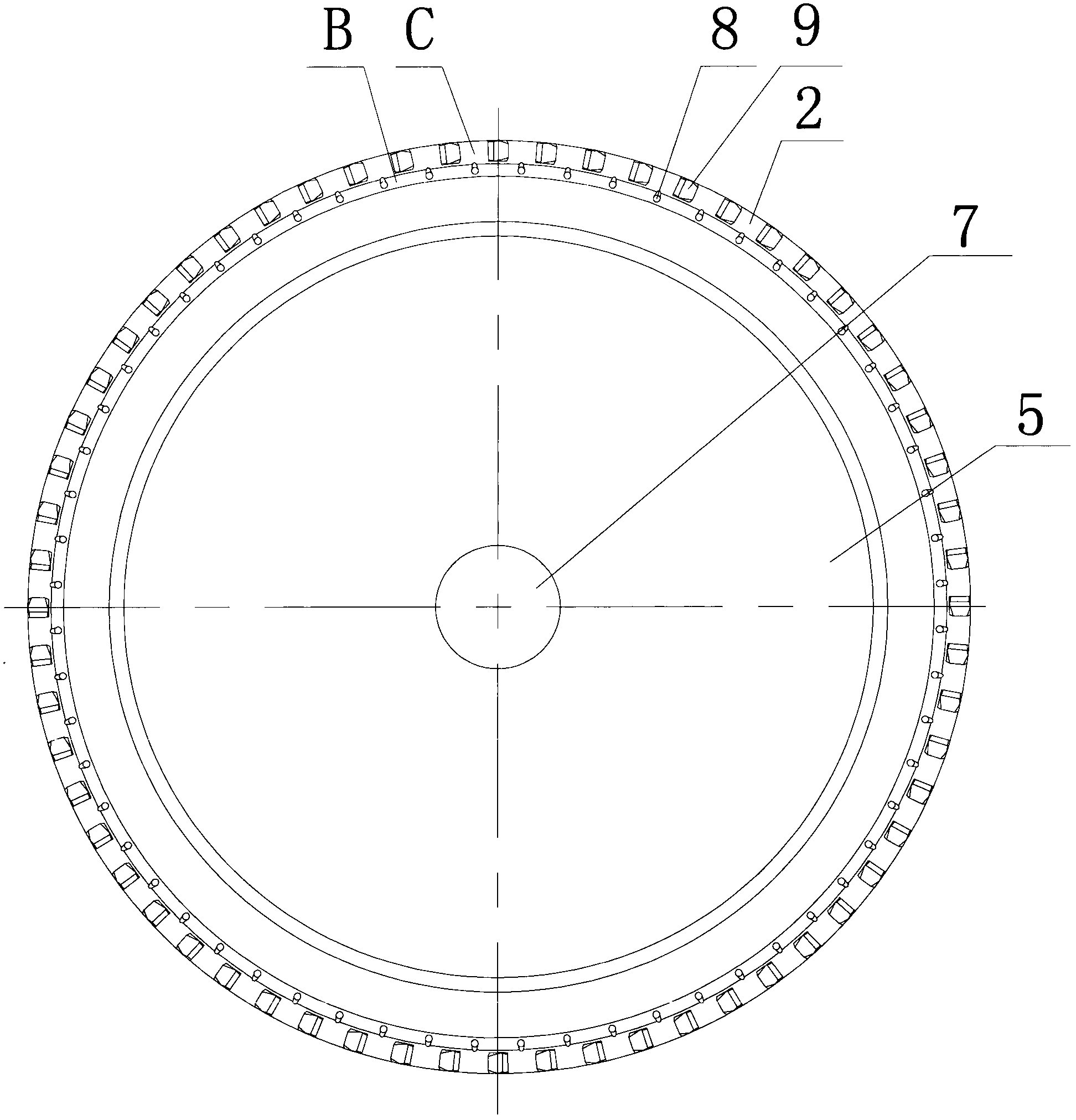

[0014] like figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of internal cooling grinding wheel, described grinding wheel body 2 is a bowl-shaped structure, on the grinding wheel body 2 there is a knife handle 1, and the abrasive grains 9 are evenly distributed under the cavity wall of the grinding wheel body, on the side of the grinding wheel body 2 There is a cooling liquid chamber 4 at the handle end, and it is sealed by a circular plate 3, and a cooling liquid injection hole 6 is arranged on the circular plate 3; In the cavity 5; in the cavity wall of the grinding wheel body 2, there are coolant channels 8 evenly distributed; the inlet of the coolant channel 8 is located in the coolant cavity 4 of the grinding wheel body, and the injection port of the coolant channel 8 is located between two adjacent abrasive grains 9. Inside; the number of coolant passages 8 is the same as the number of abrasive grains 9 . The plane B where the injection port of the cooling l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com