Process for the preparation of hydrogen cyanide

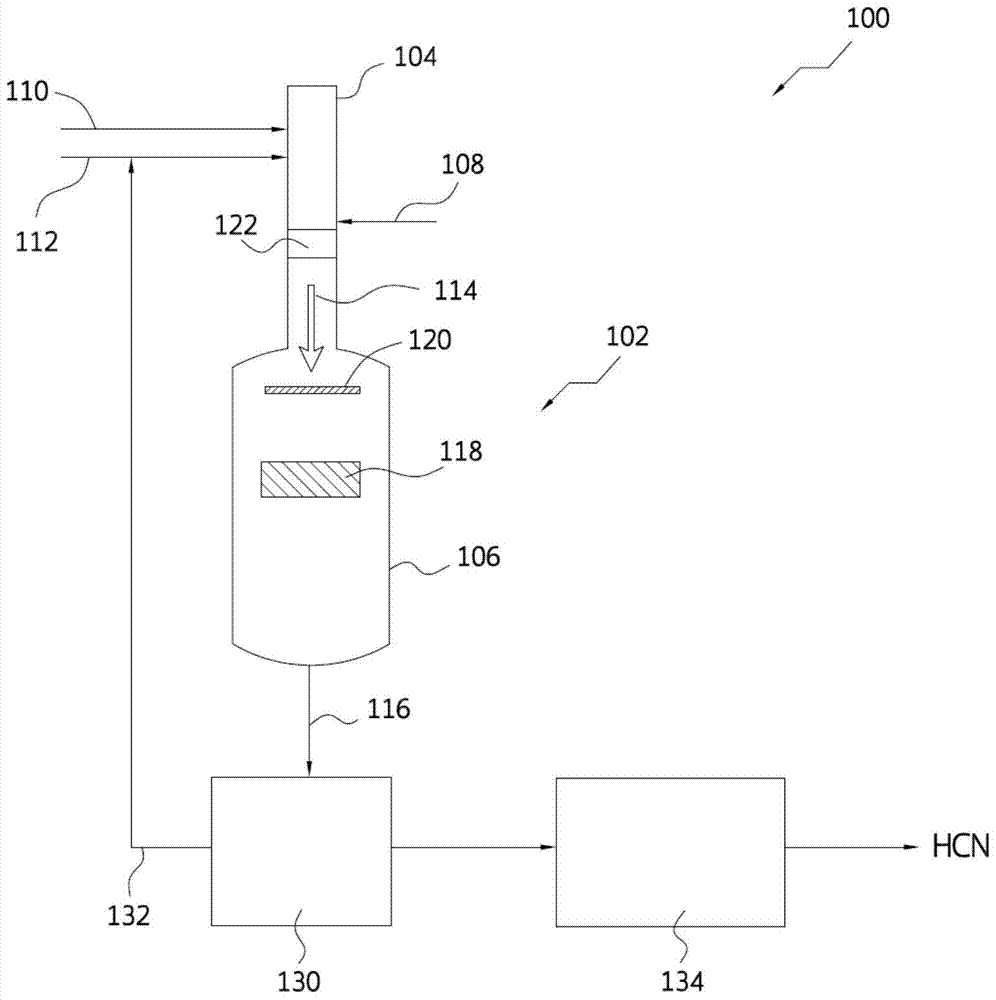

A hydrogen cyanide and catalyst bed technology, applied in the preparation/purification/separation of hydrogen cyanide, chemical instruments and methods, cyanide, etc., can solve problems related to gas reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

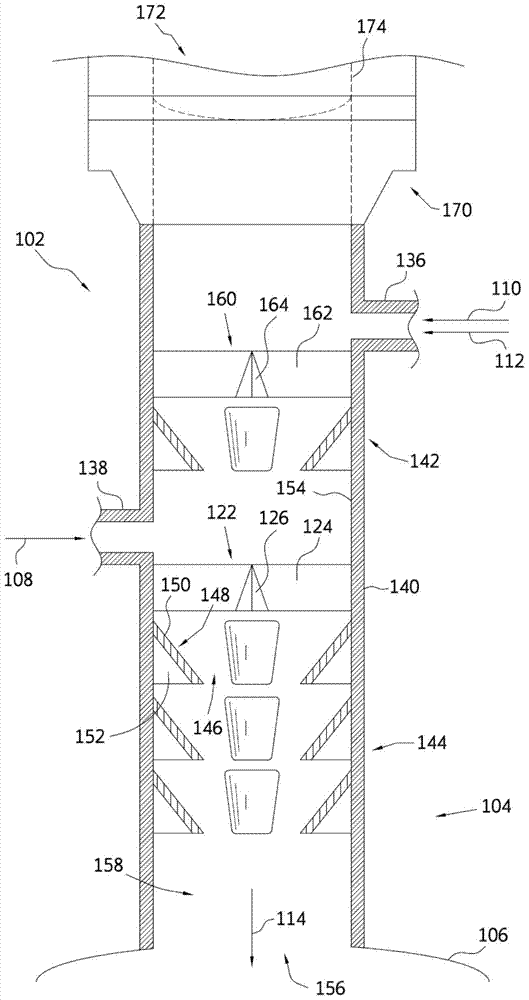

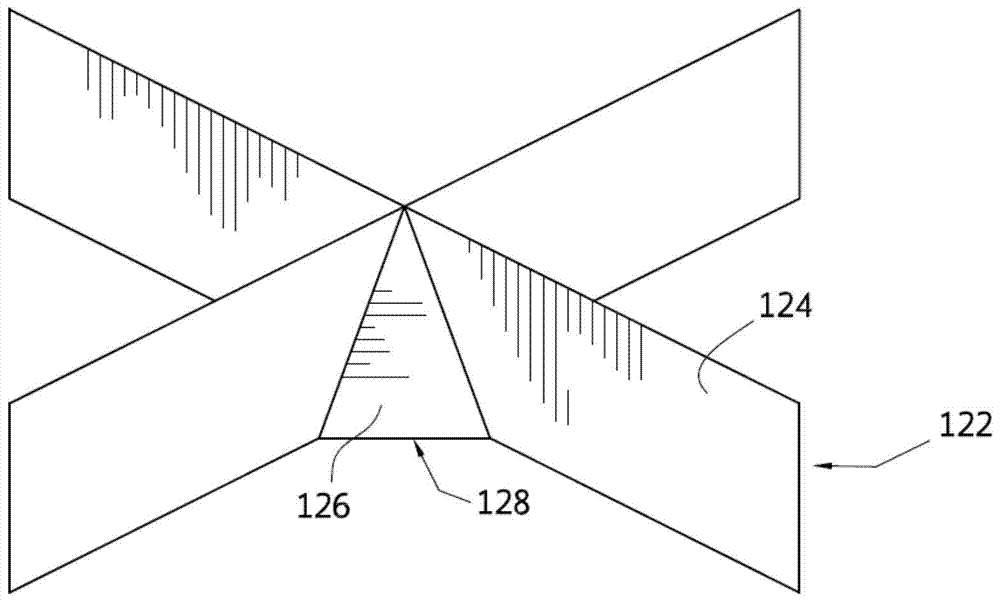

[0088] Such as figure 2 as shown in Figure 3A-3B A flow straightener with four radial plates and a pyramid-shaped center is shown positioned upstream of the static mixing zone in the mixing vessel (i.e. upstream of the tab inserts in the static mixing zone) and the annular inlet for the oxygen-containing gas downstream. The mixing vessel had a diameter of 25.4 cm and a length of 214.4 cm. A second flow straightener, also having four radial plates and a pyramid-shaped intermediate body, is arranged in the mixing vessel upstream of the second static mixing zone and downstream of the methane gas and ammonia gas inlets. Each flow corrector is 10.2 cm high and 0.95 cm thick. Each flow corrector was constructed from 310SS and had a circular ring welded to the inside of the mixing vessel. Flow correctors stop swirling flow that promotes poor mixing. The pyramid-shaped intermediate blocks the middle of the mixing vessel, thereby preventing the reactant gases from flowing throug...

example 2

[0090] The mixing vessel was run under similar conditions as in Example 1, except that each flow corrector had Figure 4A The conical intermediate shown in / 4B. This flow corrector achieves the same effect as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com