Method for enhancement of ozone oxidation degradation of pentachlorophenol in micro channel

A technology of pentachlorophenol and ozone oxidation, applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc., to achieve the effect of improving ozone utilization rate and efficient degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

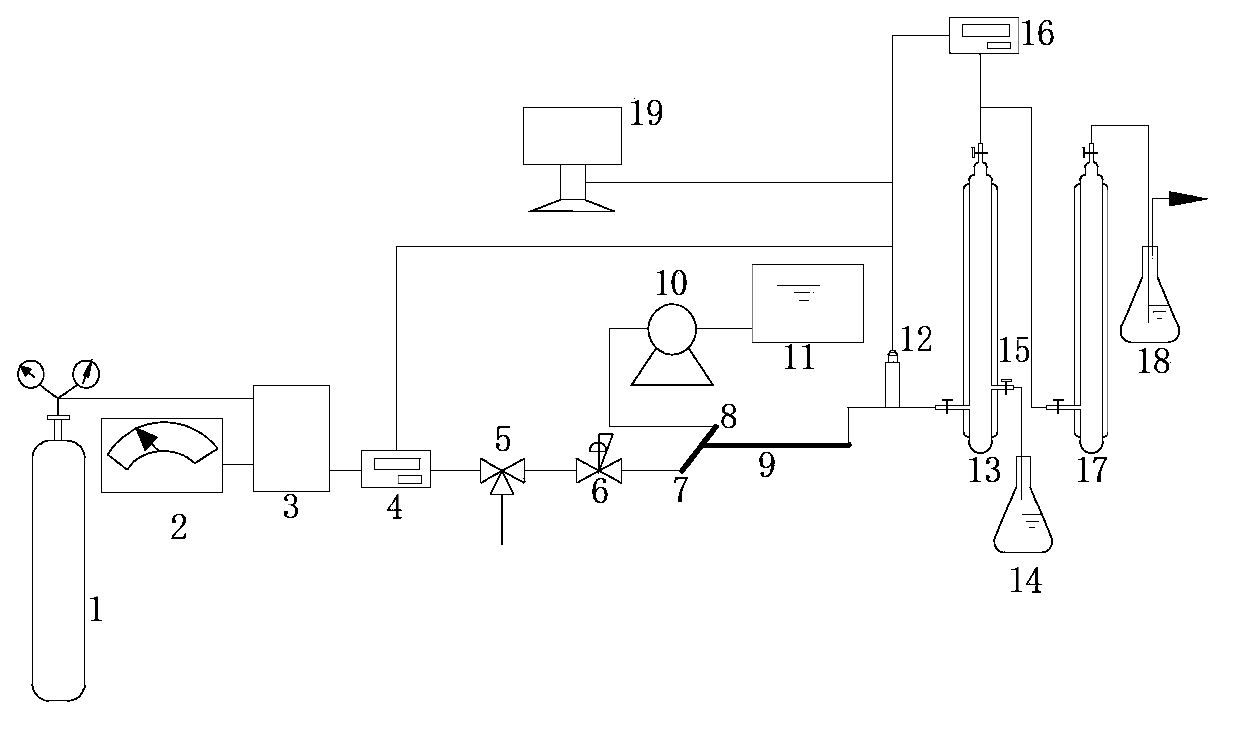

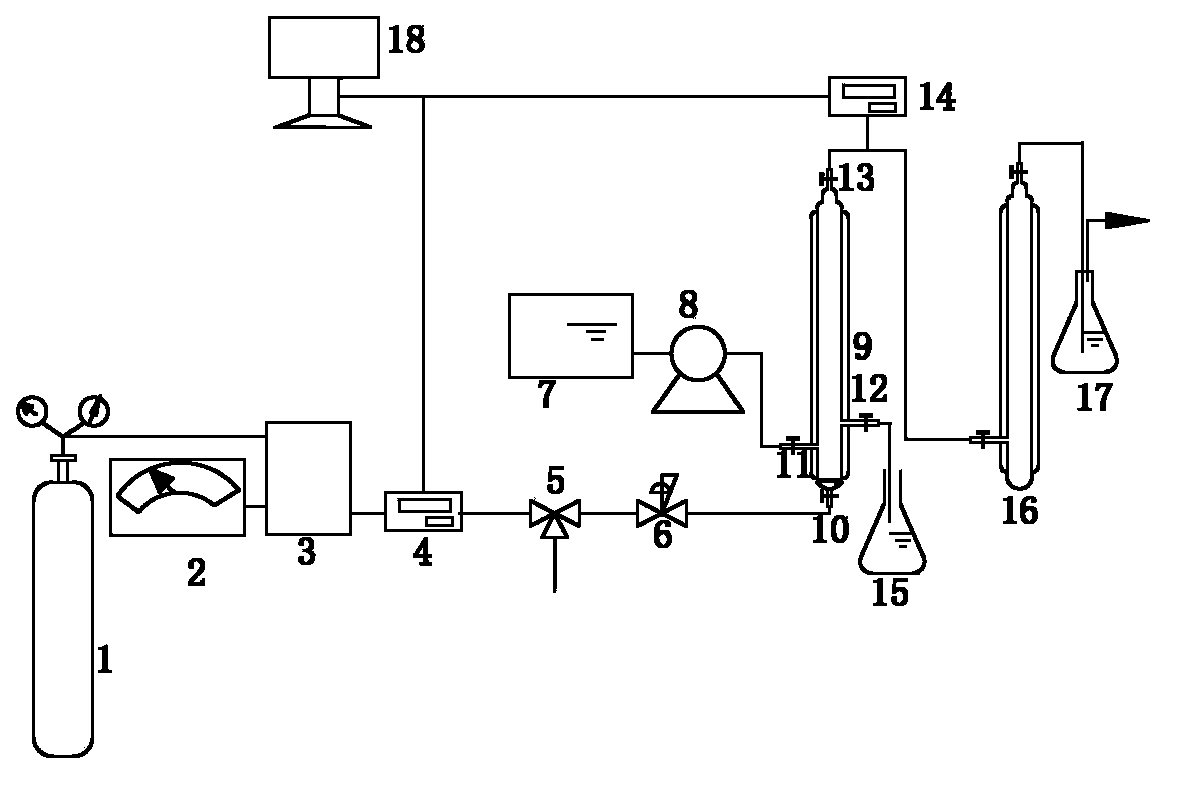

Method used

Image

Examples

Embodiment 1

[0061] 1) with 1) in Comparative Example 1;

[0062] 2) By diluting the standard stock solution, prepare 100 mL of pentachlorophenol with a concentration of 50 mg L -1 The solution to be treated, the prepared solution to be treated is added to the liquid storage tank for subsequent use;

[0063] 3) Turn on the power and start the power supply of the high-pressure liquid-phase cross-flow pump, use a syringe to extract the gas in the infusion pipeline until the liquid flow at the outlet of the high-pressure constant-flow pump is stable, and set the flow rate of the high-pressure cross-flow pump to 1.500mL min -1 , stop the pump;

[0064] 4) Adjust the gas flow rate to 10.00mL min -1 Turn on the power of the ozone generator and turn on the ozone generator to empty the ozone generated at the initial stage, and adjust the pre-pressure regulator until the reading of the gas-phase ozone concentration detector is 40.00 mg L -1 , adjust the three-way valve and the back pressure valv...

Embodiment 2

[0068] 1), 2) are the same as 1), 2) in Embodiment 1;

[0069] 3) Turn on the power and start the power supply of the high-pressure liquid-phase cross-flow pump, use a syringe to extract the gas in the infusion pipeline until the liquid flow at the outlet of the high-pressure constant-flow pump is stable, and set the flow rate of the high-pressure cross-flow pump to 2.452mL min -1 , stop the pump;

[0070] 4) Adjust the gas flow to 50.00mL min -1 Turn on the power of the ozone generator and turn on the ozone generator to empty the ozone generated at the initial stage, and adjust the pre-pressure regulator until the reading of the gas-phase ozone concentration detector is 30.00 mg L -1 , adjust the three-way valve and the back pressure valve, and stabilize the flow rate of the gas entering the branch of the microchannel reactor at 5.58mL min -1 ;

[0071] 5) Close the ozone vent valve, and then turn on the high-pressure liquid-phase constant-flow pump. The outlet of the gas-...

Embodiment 3

[0074] 1) with 1) in embodiment 1;

[0075] 2) By diluting the standard stock solution, prepare 100 mL of pentachlorophenol with a concentration of 20 mg L -1 The solution to be treated, the prepared solution to be treated is added to the liquid storage tank for subsequent use;

[0076] 3) Turn on the power and start the power supply of the high-pressure liquid-phase cross-flow pump, use a syringe to extract the gas in the infusion pipeline until the liquid flow at the outlet of the high-pressure constant-flow pump is stable, and set the flow rate of the high-pressure cross-flow pump to 1.608mL min -1 , stop the pump;

[0077] 4) Adjust the gas flow rate to 10.00mL min -1 Turn on the power of the ozone generator and turn on the ozone generator to empty the ozone generated at the initial stage, and adjust the pre-pressure regulator until the reading of the gas-phase ozone concentration detector is 30.00 mg L -1 , adjust the three-way valve and the back pressure valve, and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com