Biomass filler anaerobic filter tank for treating oxidation-state pollutants

A technology of biological filter and anaerobic filter, which is applied in the direction of anaerobic digestion and treatment, and can solve the problems of restricting wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

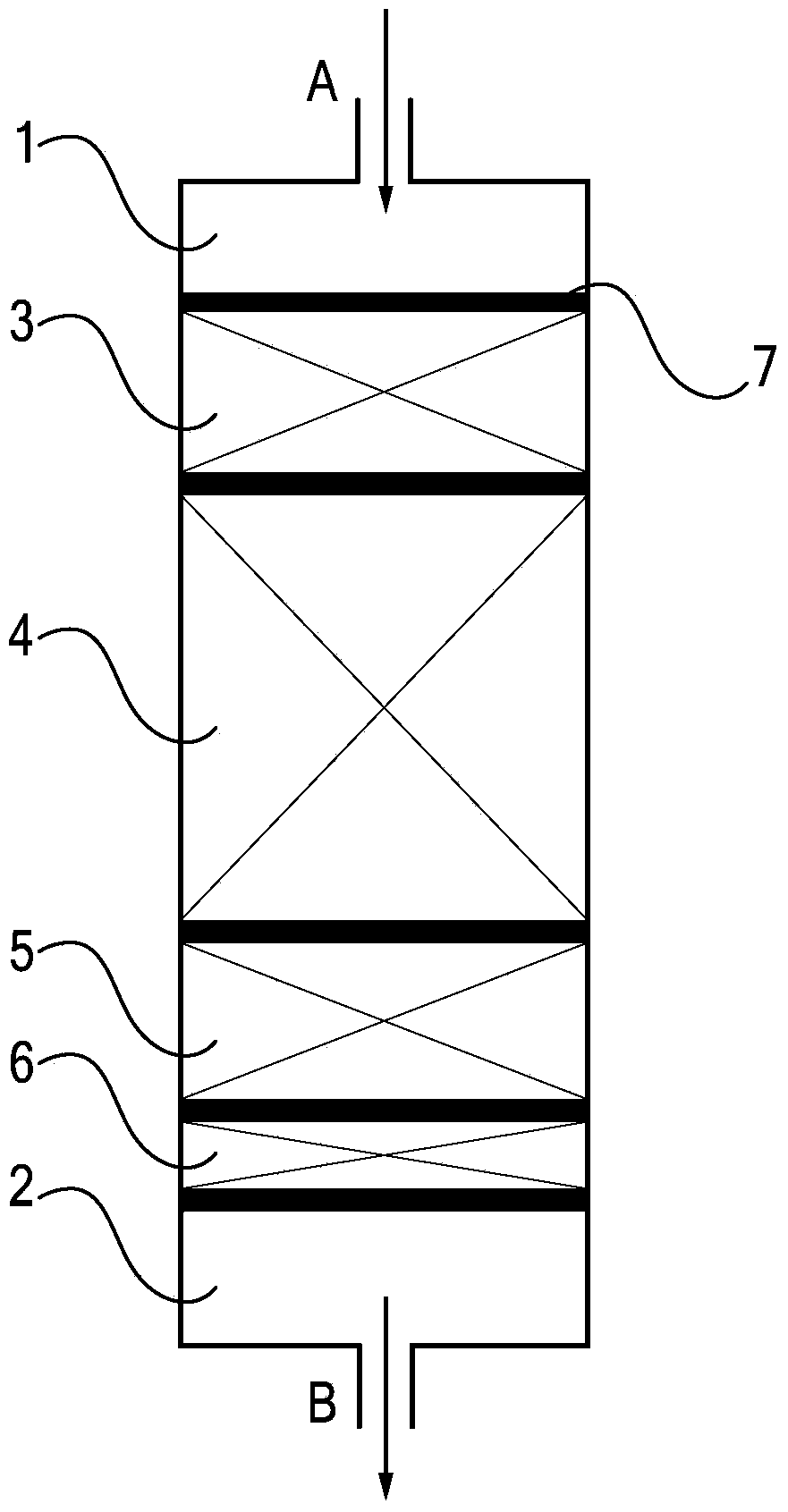

[0022] Example 1. As figure 1 As shown, a biomass filled anaerobic filter, the operation mode is downward flow, and the effluent is provided with internal circulation.

[0023] The biomass filler anaerobic filter that embodiment 1 adopts comprises common biological filter, biomass filler;

[0024] The biomass filler is composed of natural henna plant stems and ceramsite; the average length of henna plant stems after crushing is 10 mm, and the average particle size of ceramsite is 20 mm;

[0025] There is a support plate 7 in the ordinary biological filter, which is used to place the biomass filler; one end of the ordinary biological filter is provided with a water inlet A, and the other end is provided with a water outlet B; the water flow direction from the water inlet A to the water outlet B, A water inlet buffer zone 1, a filter filter zone, and a water outlet buffer zone 2 are sequentially arranged in an ordinary biological filter, and a support plate 7 is arranged betwee...

Embodiment 2

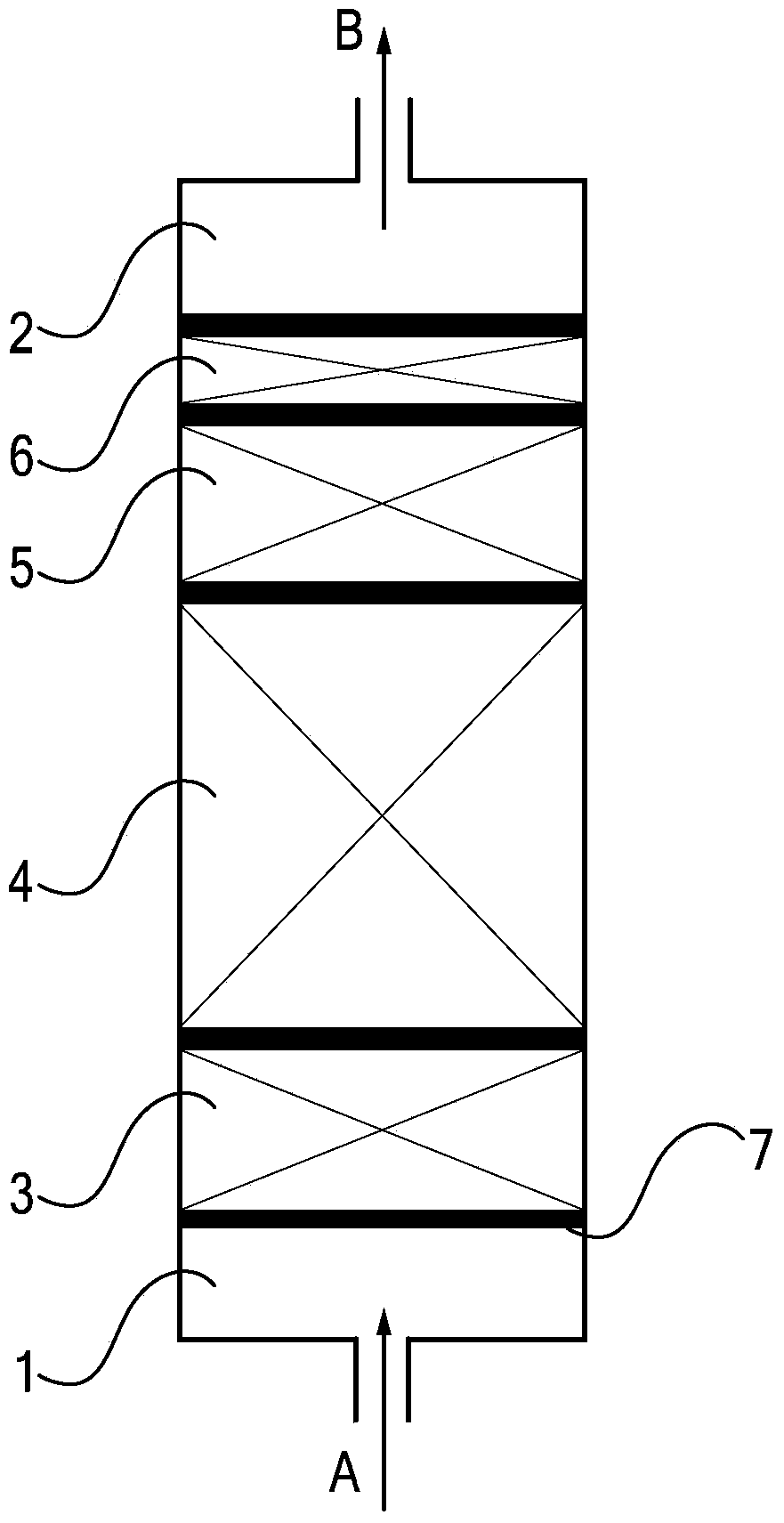

[0028] Example 2. If figure 2 As shown, a biomass filled anaerobic filter, the operation mode is upward flow, and the effluent is provided with internal circulation

[0029] The biomass filler anaerobic filter that embodiment 2 adopts comprises ascending type filler filter, biomass filler;

[0030]The biomass filler is composed of natural henna plant leaves and volcanic rock mountains; the average particle size of henna plant leaves after crushing is 5 mm, and the average particle size of volcanic rocks is 7 mm;

[0031] There is a support plate 7 inside the ascending packing filter, which is used to place biomass packing; one end of the ascending packing filter is provided with a water inlet A, and the other end is provided with a water outlet B; the water flow from the water inlet A to the water outlet B Direction, in the ascending packed filter tank, there are water inlet buffer zone 1, filter tank filtration zone, and water outlet buffer zone 2 in sequence, and a support...

Embodiment 3

[0034] Example 3. As figure 1 As shown, a biomass filled anaerobic filter, the operation mode is downward flow, and the effluent is provided with internal circulation

[0035] The biomass filler anaerobic filter that embodiment 3 adopts comprises tower type biofilter, biomass filler;

[0036] The biomass filler is composed of natural henna plant seeds and steel slag; the henna plant seeds are inactivated at 121°C and 0.12MPa for 1 h before use, the average particle size is 2 mm, and the average particle size of steel slag is 3 mm;

[0037] There is a supporting plate 7 inside the tower biofilter, which is used to place biomass filler; one end of the tower biofilter is provided with a water inlet A, and the other end is provided with a water outlet B; the water flow from the water inlet A to the water outlet B In the tower type biofilter, there are water inlet buffer 1, filter filter area, and outlet buffer 2 in sequence, and a support plate 7 is provided between the water inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com