Efficient coal-water slurrygasification ash water treatment method

A treatment method, coal water slurry technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the fouling and blockage of the tower kettle reboiler, which cannot be stabilized for a long period of time Problems such as running and fouling tend to be serious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

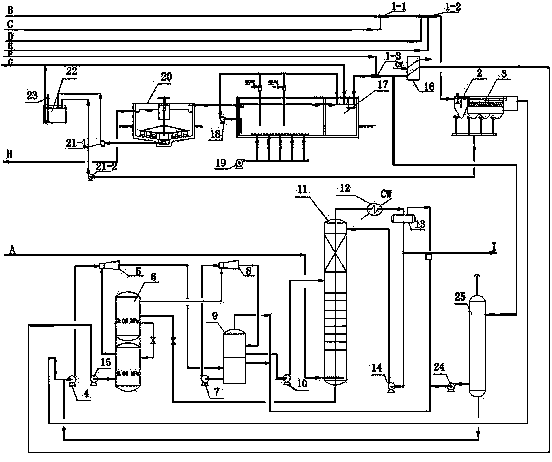

[0035] figure 1Description of marks: pipeline mixer 1-1~1-3, reaction tank 2, sedimentation tank 3, secondary injector feed pump 4, secondary injector 5, flash tower 6, primary injector feed pump 7. Primary jet pump stripper 8, gray water storage tank 9, stripper feed pump 10, stripper 11, reflux condenser 12, reflux tank 13, reflux pump 14, lift pump 15, gray water cooling device 16, A / O reaction tank 17, jet circulation pump 18, aeration blower 19, secondary settling tank 20, sludge lifting pumps 21-1, 21-2, sludge storage tank 22, sludge delivery pump 23, lead Fan 24, washing tower 25, low-pressure steam A, coal-water slurry gasification gray water B, lye C, PAM D, PAC E, dilute hydrochloric acid F, sludge G, standard gray water H, and recycled ammonia water I.

[0036] figure 1 It is a patent embodiment of the present invention, which consists of 3 units of gray water pretreatment, stripping to remove ammonia and biochemical treatment. The steps are:

[0037] 1) CWS gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com